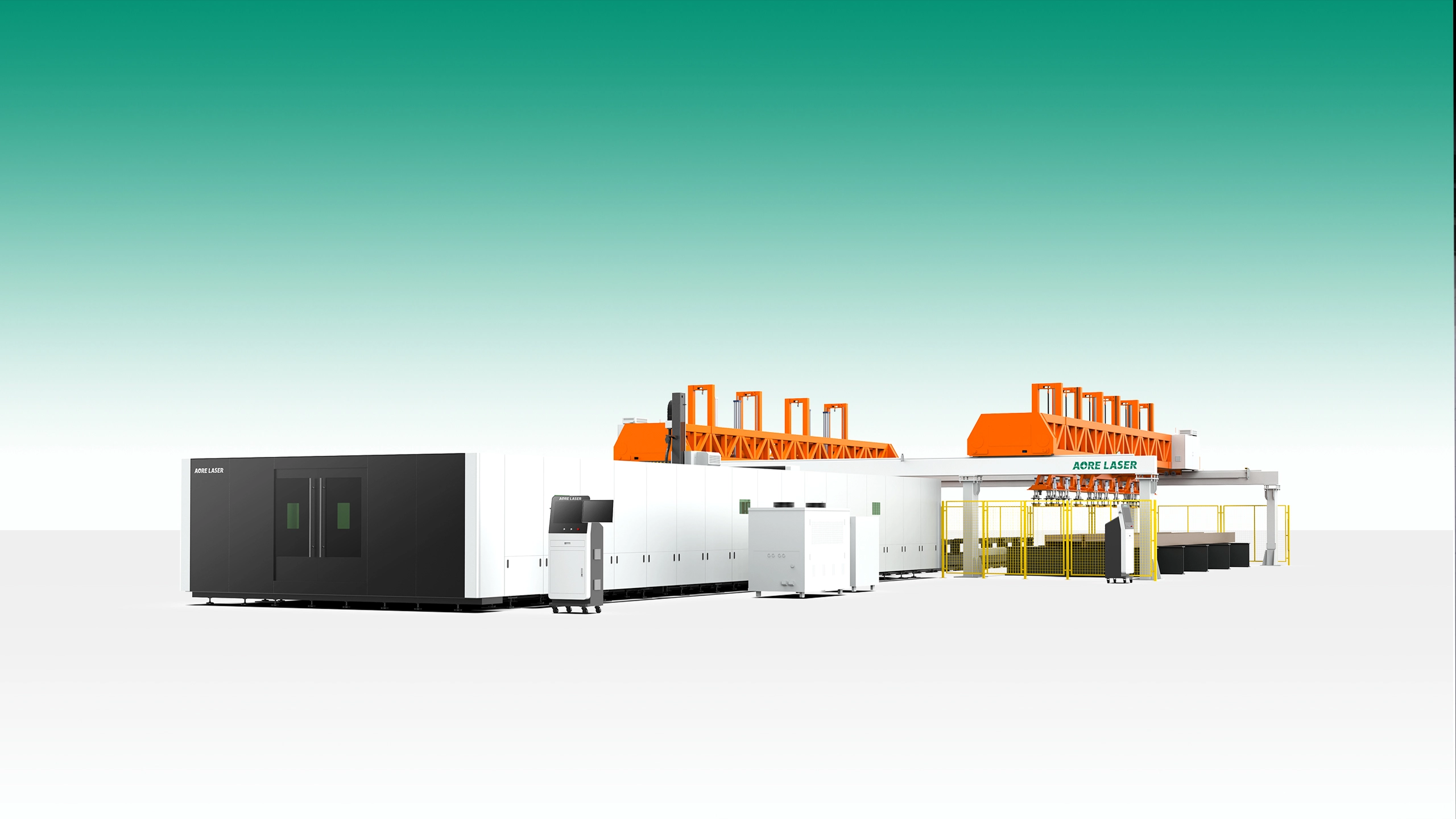

Automated Profile Loading & Unloading System

Revolutionizes production through automation, doubling both capacity and efficiency.

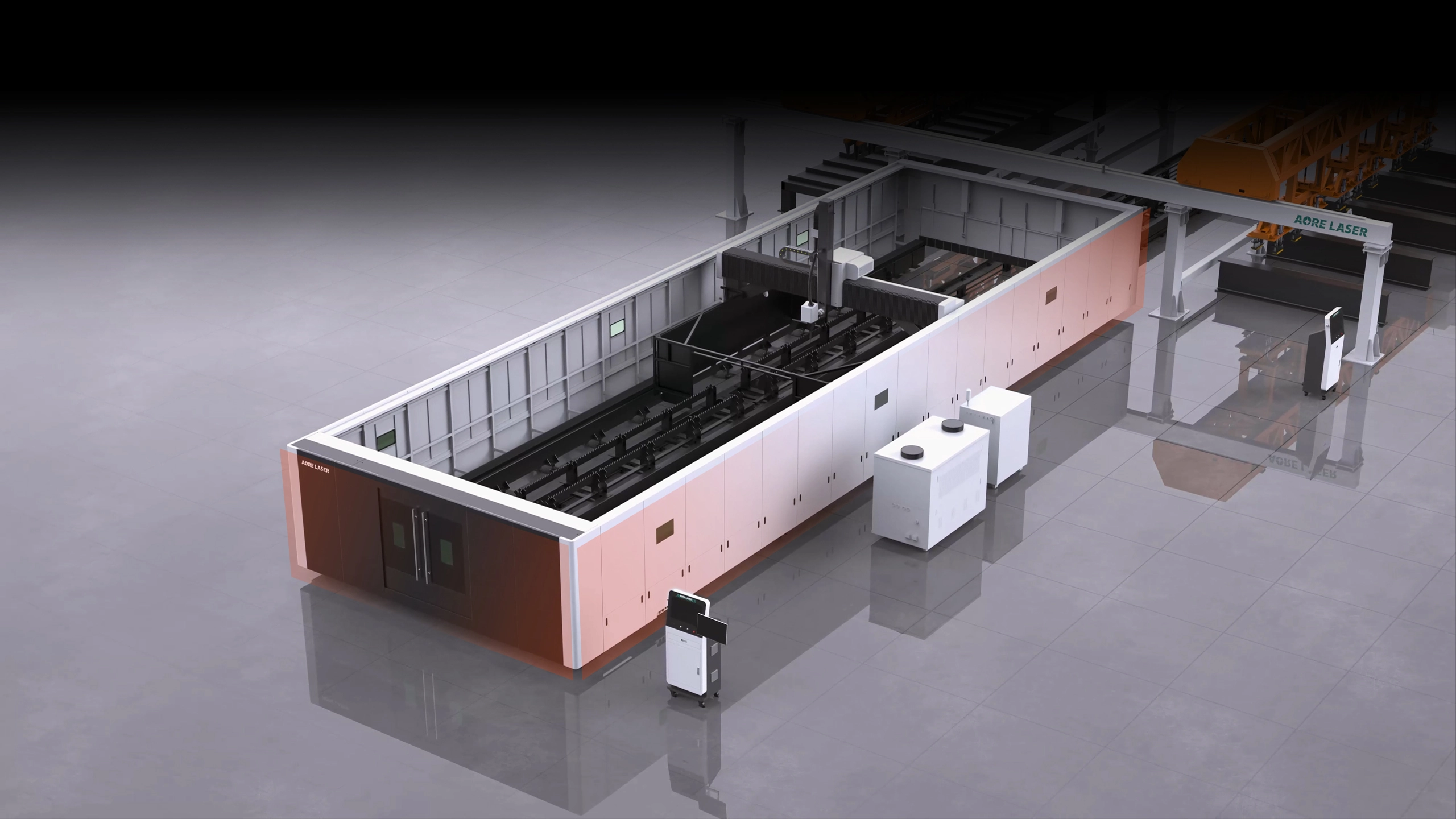

Fully-Enclosed Protection

A fully enclosed safety cover creates a sealed barrier for operator isolation, ensuring safe production.

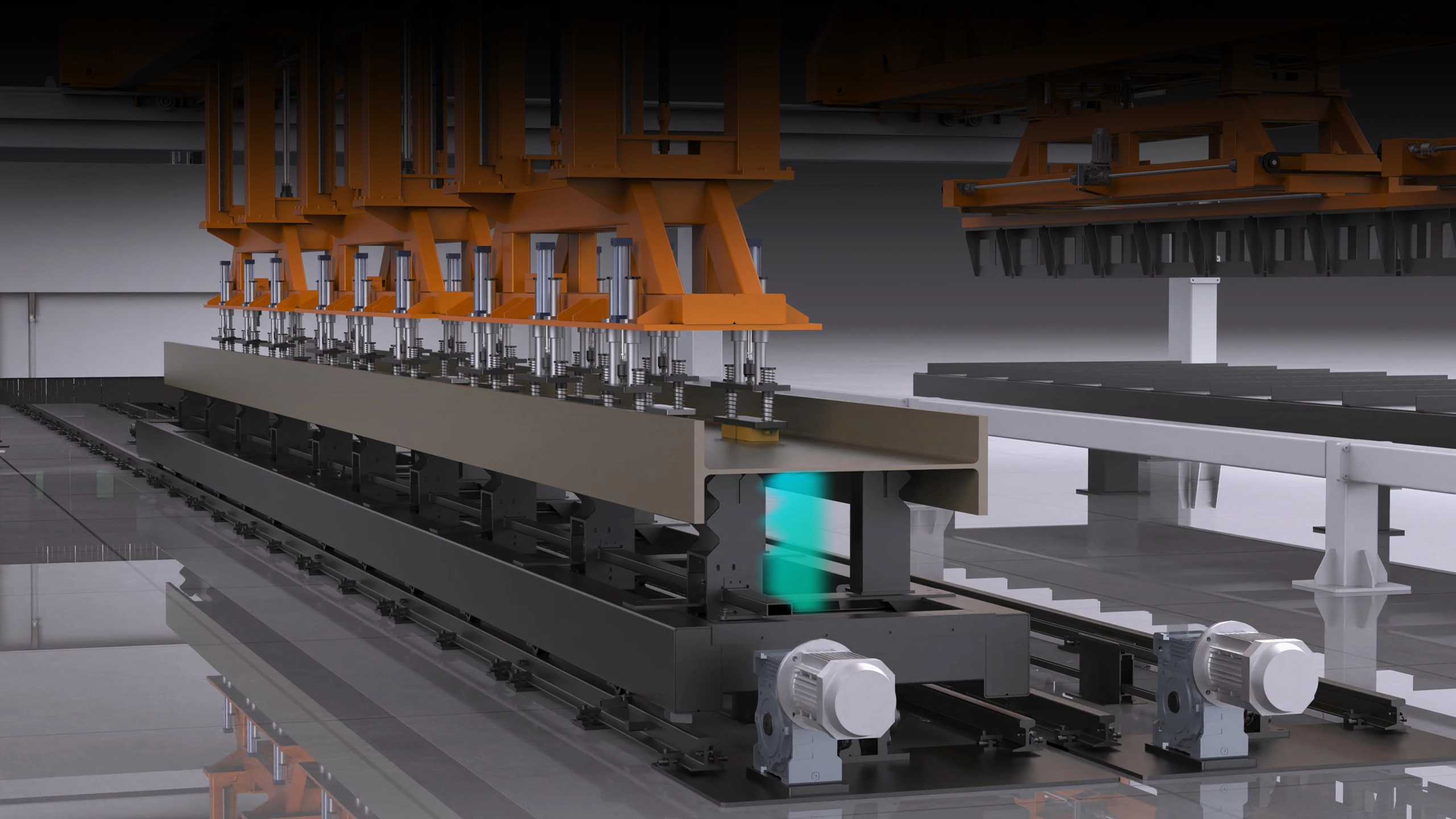

Vision-Centred Precision Positioning

High-precision 3D vision scanning enables unmanned, accurate alignment for efficient and precise processing.

Magnetic Loading

Magnetic adsorption allows adaptive, non-damaging loading of various profiles, meeting diverse production needs.

Pneumatic Adjustment System

Automatically adjusts the support width to ensure stable and high-precision processing.

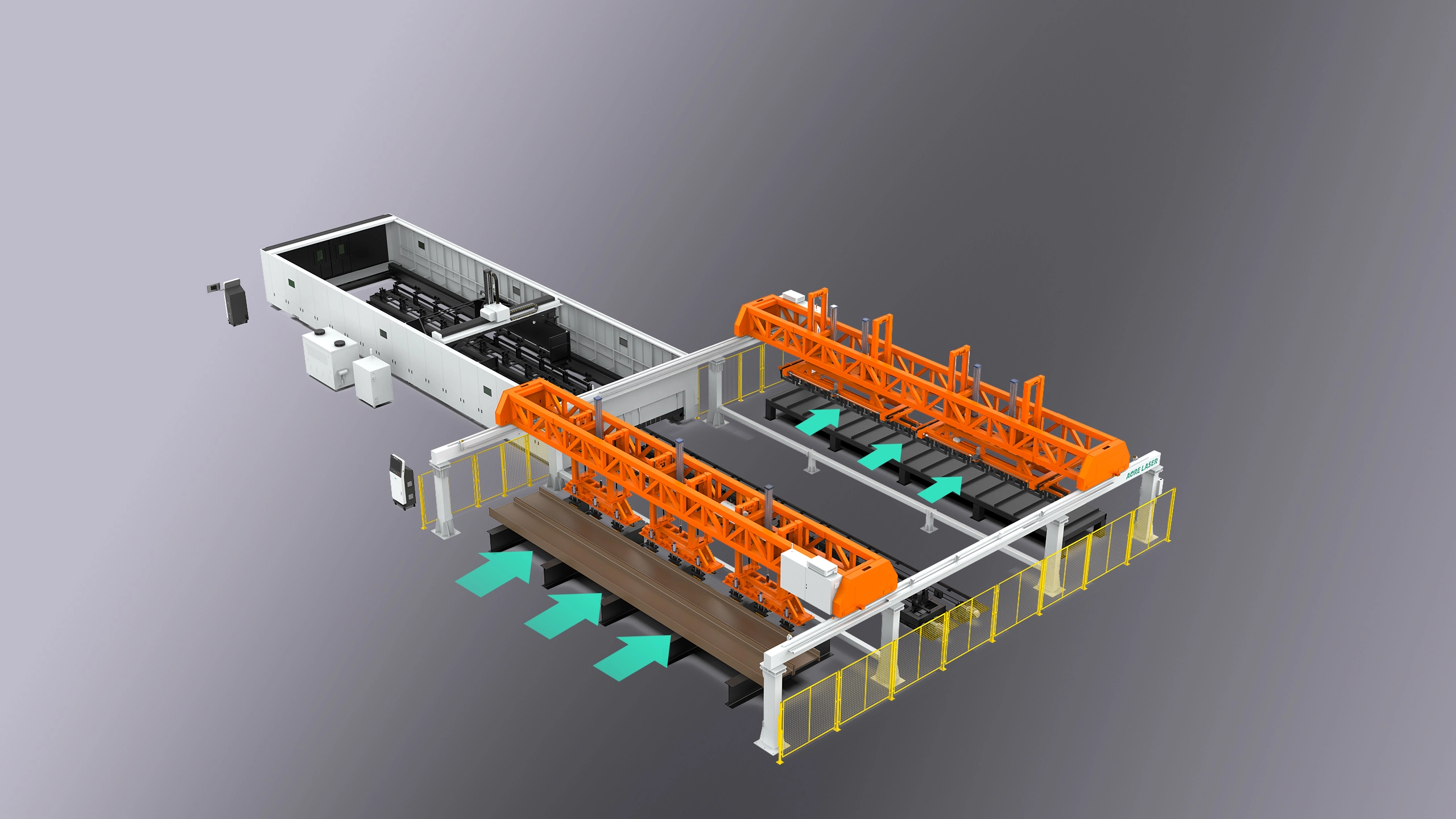

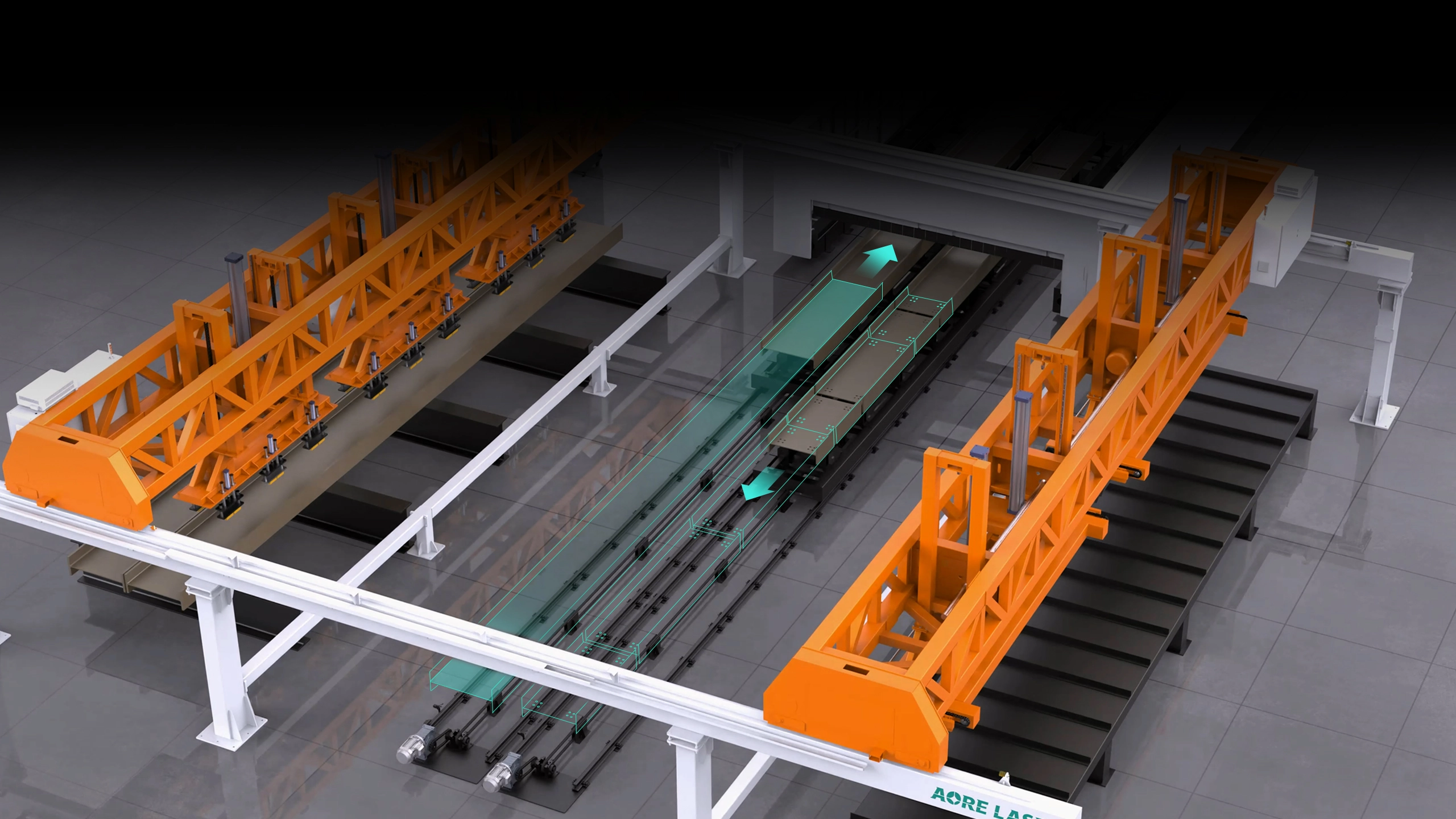

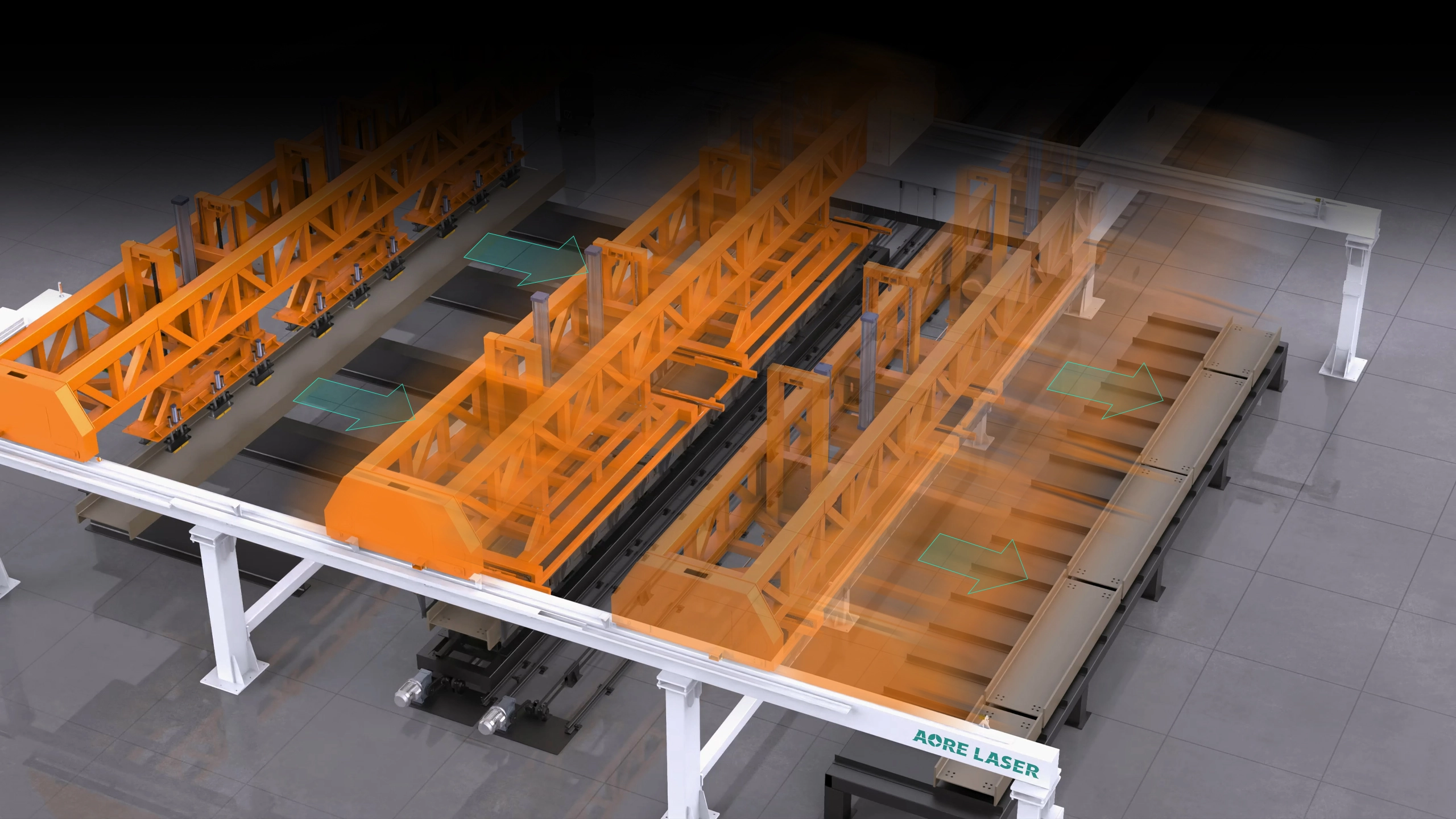

Smart Dual-Station Exchange Design

Dual-station coordination maximizes machine utilization and boots overall productivity.

Dual-Station Linked Operation

Automated alternating loading and unloading between two stations ensures seamless workflow continuity.

Applications

Bridge Construction

Rail Transit

Shipbuilding

Power Transmission Towers

Steel Structure

Technical Parameters

| Model | H-ALS |

|---|---|

| Power | 12-40kW |

| Section Size for Profile Processing | 300*150mm-800*500mm(Customization available upon request) |

| Max. Length of Profile | 12000mm |

| Max. Loading Capacity | 5T |

| Max. X/Y-Axis Linkage Positioning Speed | 80m/min |

| Max. X/Y-Axis Linkage Positioning Acceleration | 0.8G |