High-Stability Laser Source

Delivers consistent, high-efficiency performance, ensuring stable machine operation.

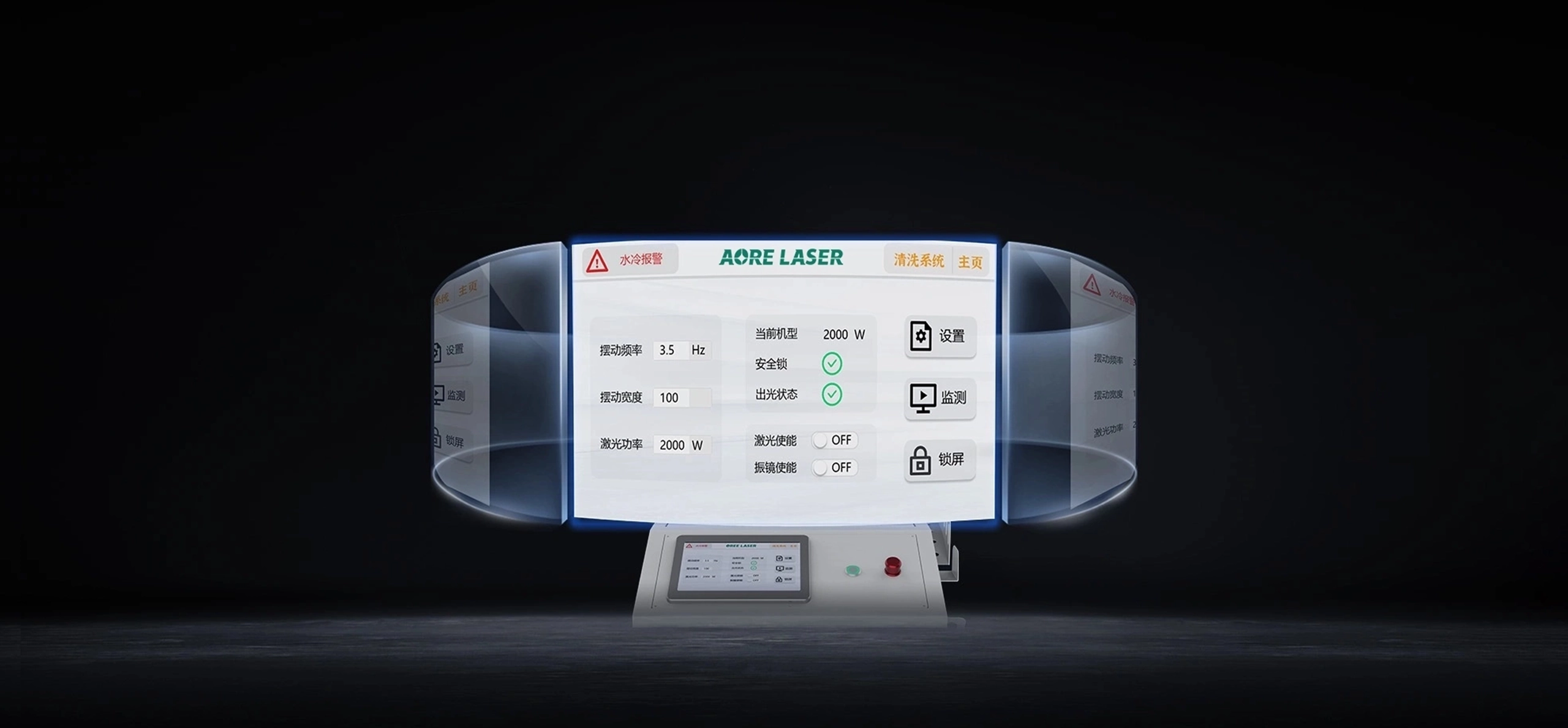

Intelligent Control System

Supports parameter customization to accommodate various materials and cleaning process requirements.

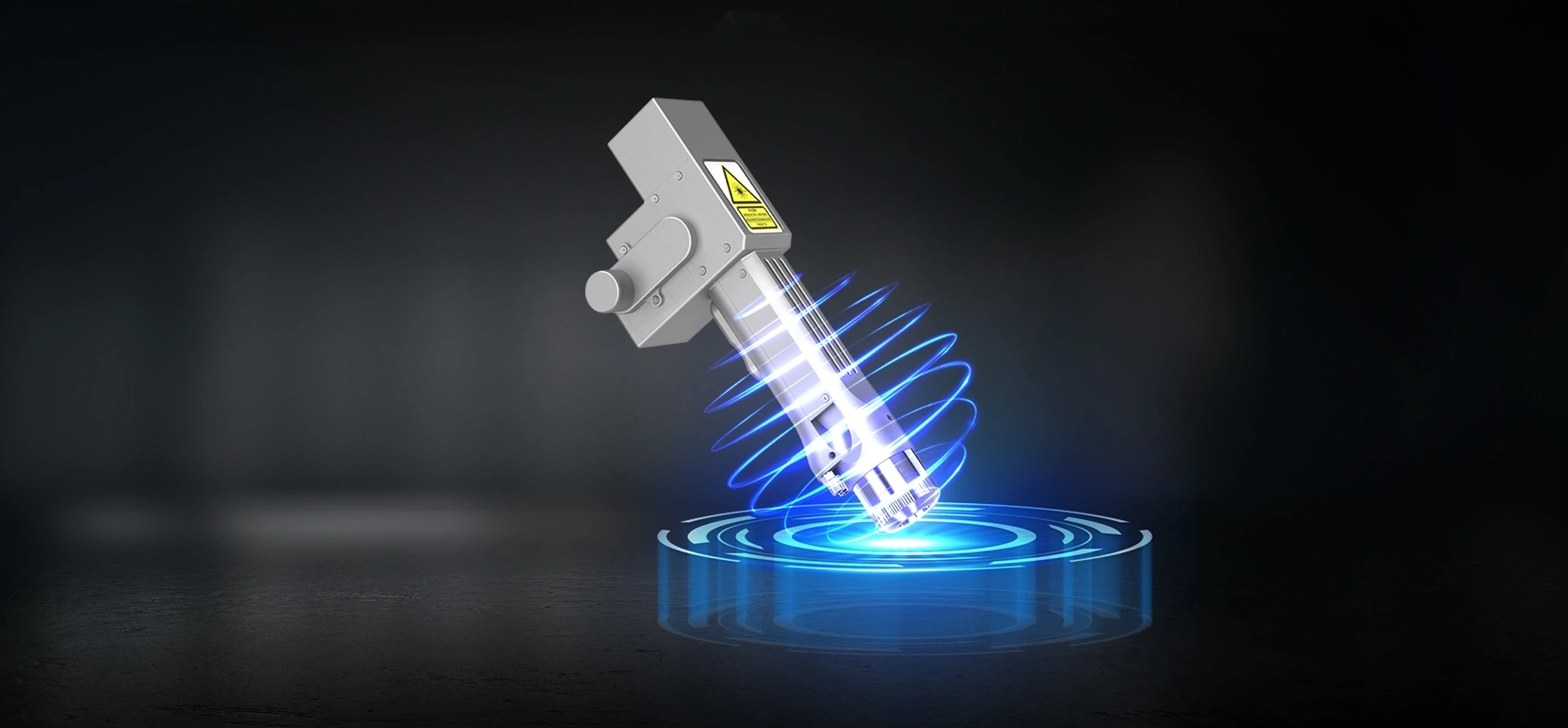

Handheld Operation Head

Compact and ergonomic design offers flexibility for multi-scenario applications and supports agile, on-site manufacturing needs.

Professional Cleaning System

Integrates multiple cleaning modes with one-click smart operation for efficient and simplified cleaning tasks.

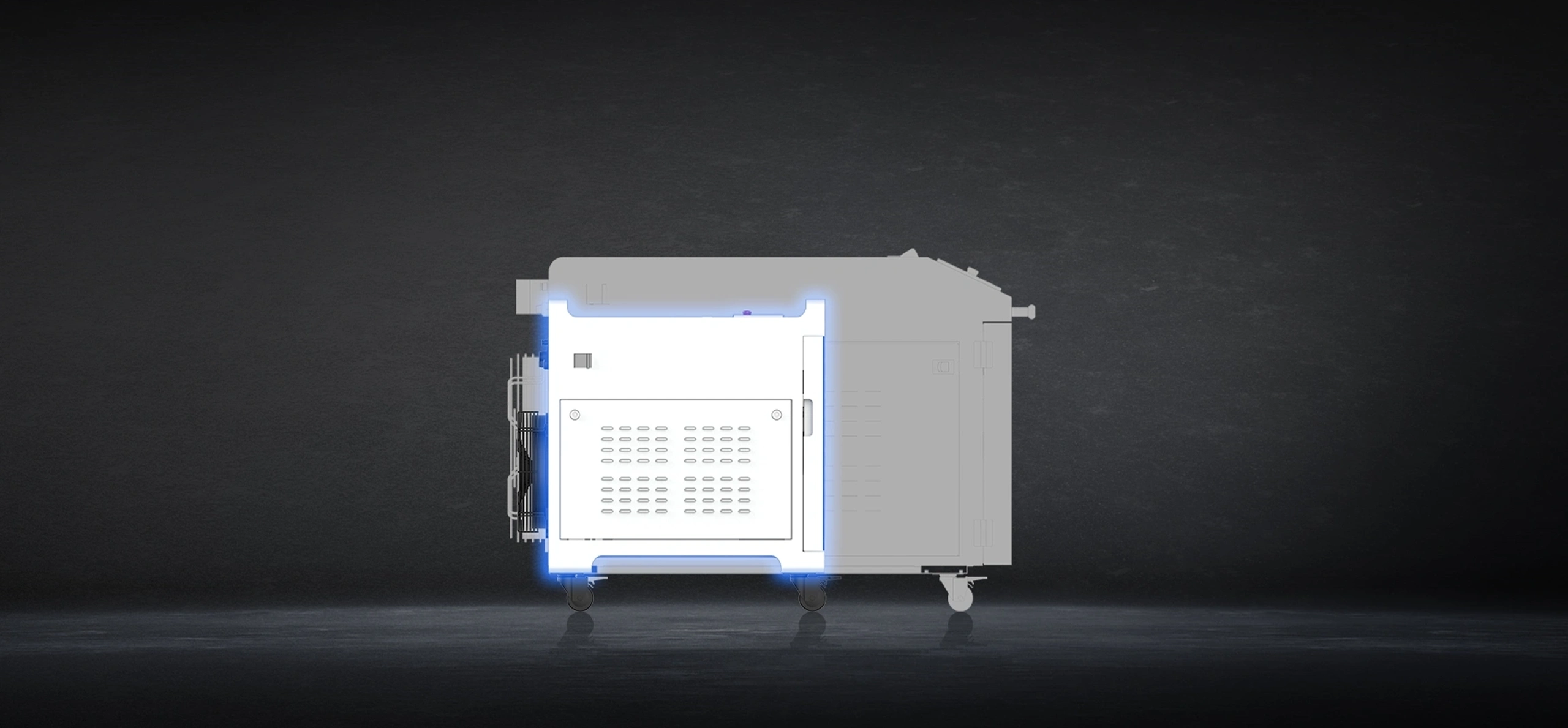

Smart Design, Safe and Stable

Compact and portable with user-friendly controls. Highly integrated system ensures reliable and safe performance.

Professional Cleaning Head for Efficient and Convenient Operation

Lightweight ergonomic design with smart sensing ensures responsive, precise, and user-friendly cleaning.

Applications

Railway Transportation

Automotive

Ship Repair

Cultural Heritage Restoration

Mold Manufacturing

Technical Parameters

| Model | LC-1500W | LC-2000W | LC-3000W |

|---|---|---|---|

| Power | 1500W | 2000W | 3000W |

| Equipment size | 950*660*930mm | 950*660*930mm | 1100*660*970mm |

| Weld seam requirements | 1080±10 nm | 1080±10 nm | 1080±10 nm |

| Welding speed | 8-40m²/h | 10-60m²/h | 20-80m²/h |

| Cooling method | Intelligent Dual-temperature and Dual-control Chiller | Intelligent Dual-temperature and Dual-control Chiller | Intelligent Dual-temperature and Dual-control Chiller |

| Operating temperature range | 5-40℃ | 5-40℃ | 5-40℃ |