Robust Load Capacity, Versatile Tube Processing

Full-Length Tube Cutting with Zero Scrap

Full-Stroke Intelligent Support

Flexible Solution for Diverse Cutting Needs

End-to-End Automation (Optional)

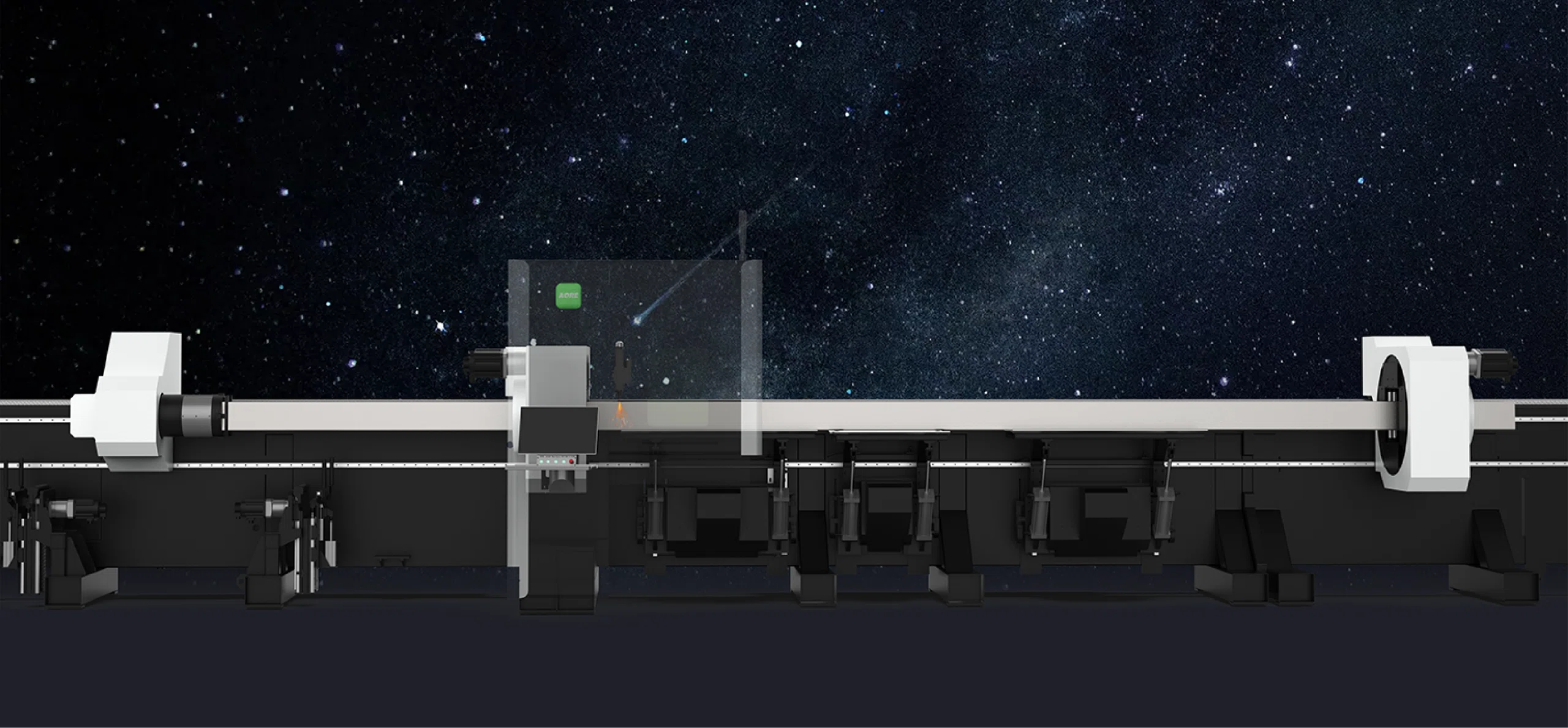

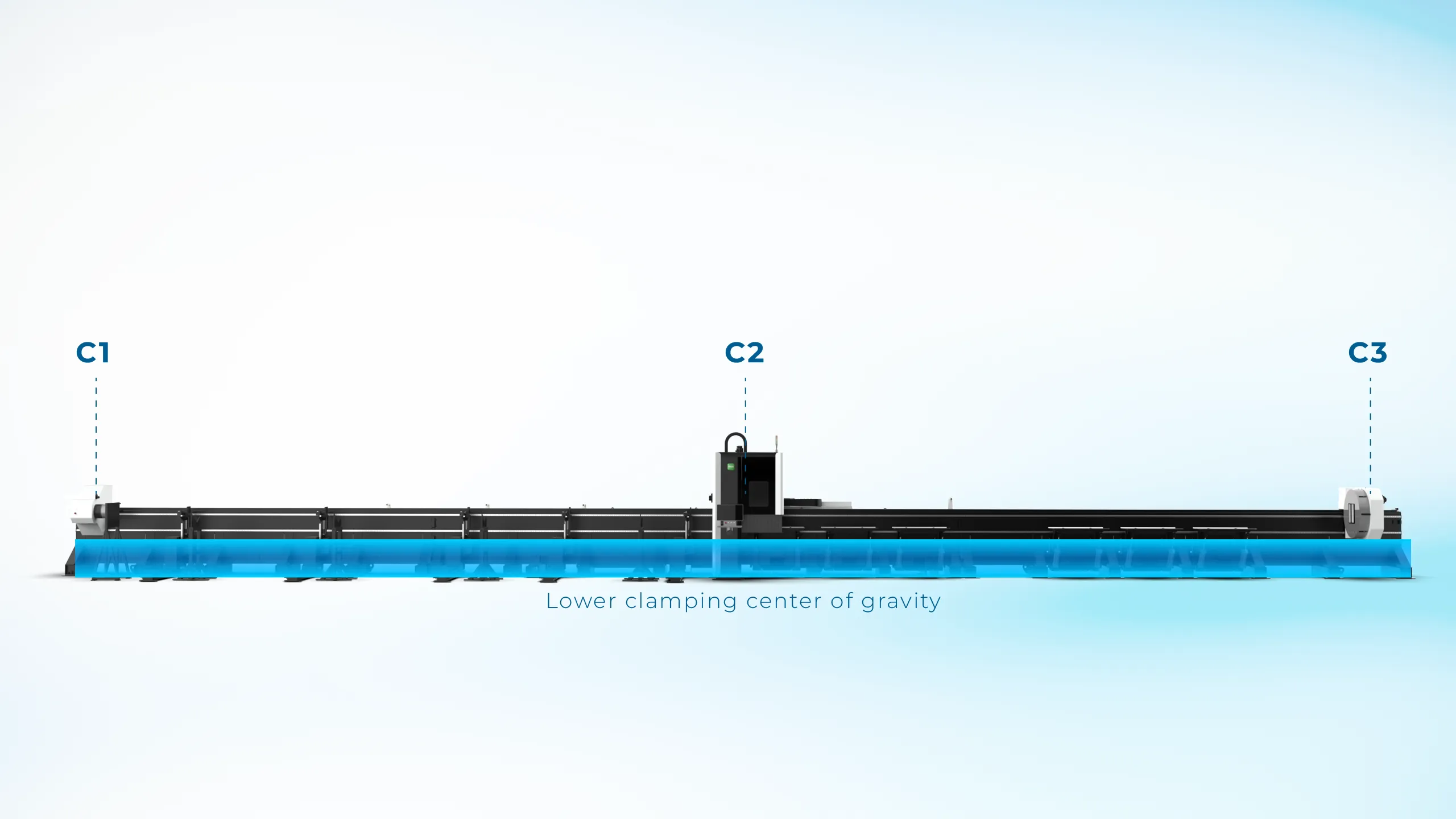

Engineered with a heavy-duty side-mounted bed design, the machine offers a low center of gravity and exceptional structural stability, ensuring outstanding load-bearing performance. Equipped with a three-chuck clamping for large-diameter tubes, it securely holds tubes of various sizes and materials—supporting a wide range of processing applications while enhancing production efficiency and machining precision.

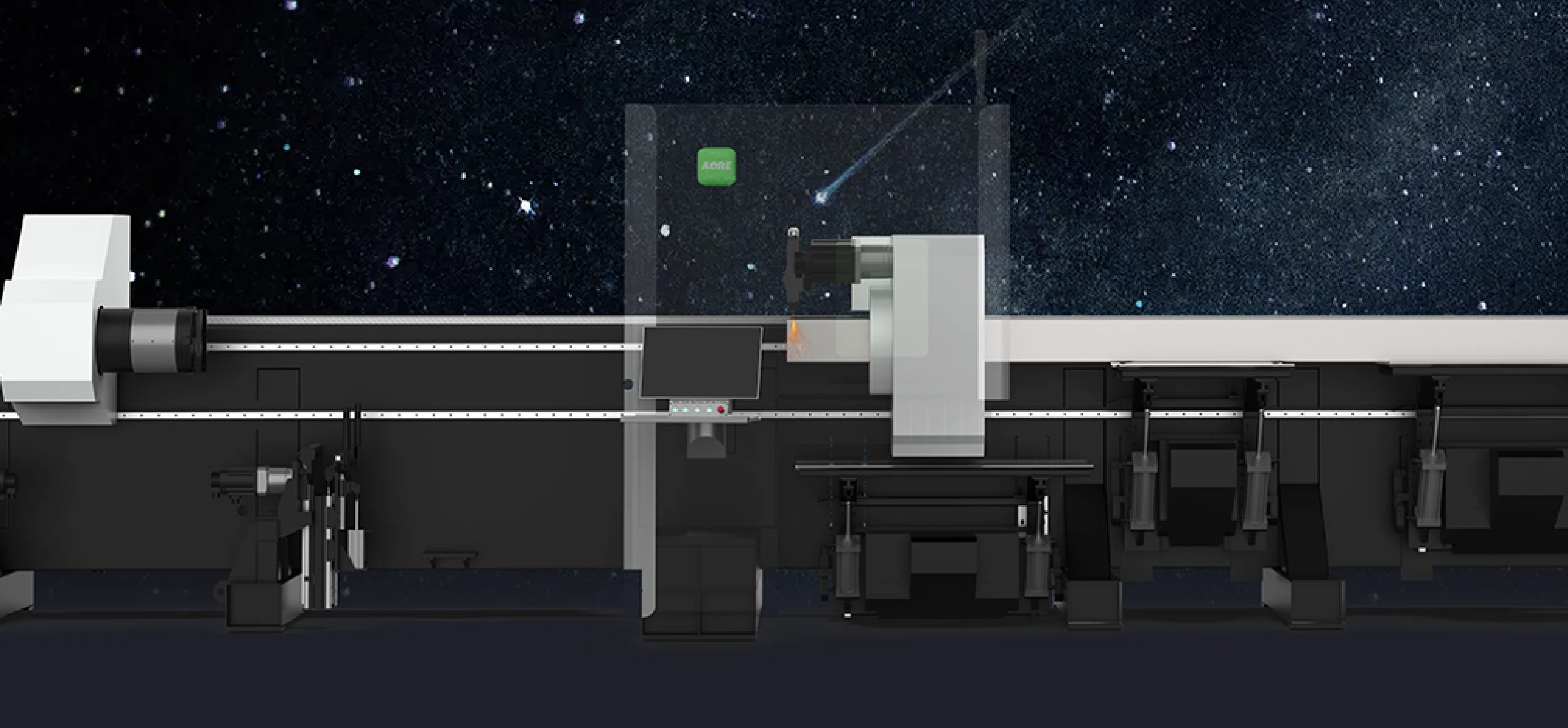

Featuring a triple chuck system with independently movable chucks, the machine enables unrestricted cutting of long and full-length tubes. This innovative design ensures highly precise clamping and cutting with zero tail material, maximizing material utilization and significantly reducing production costs.

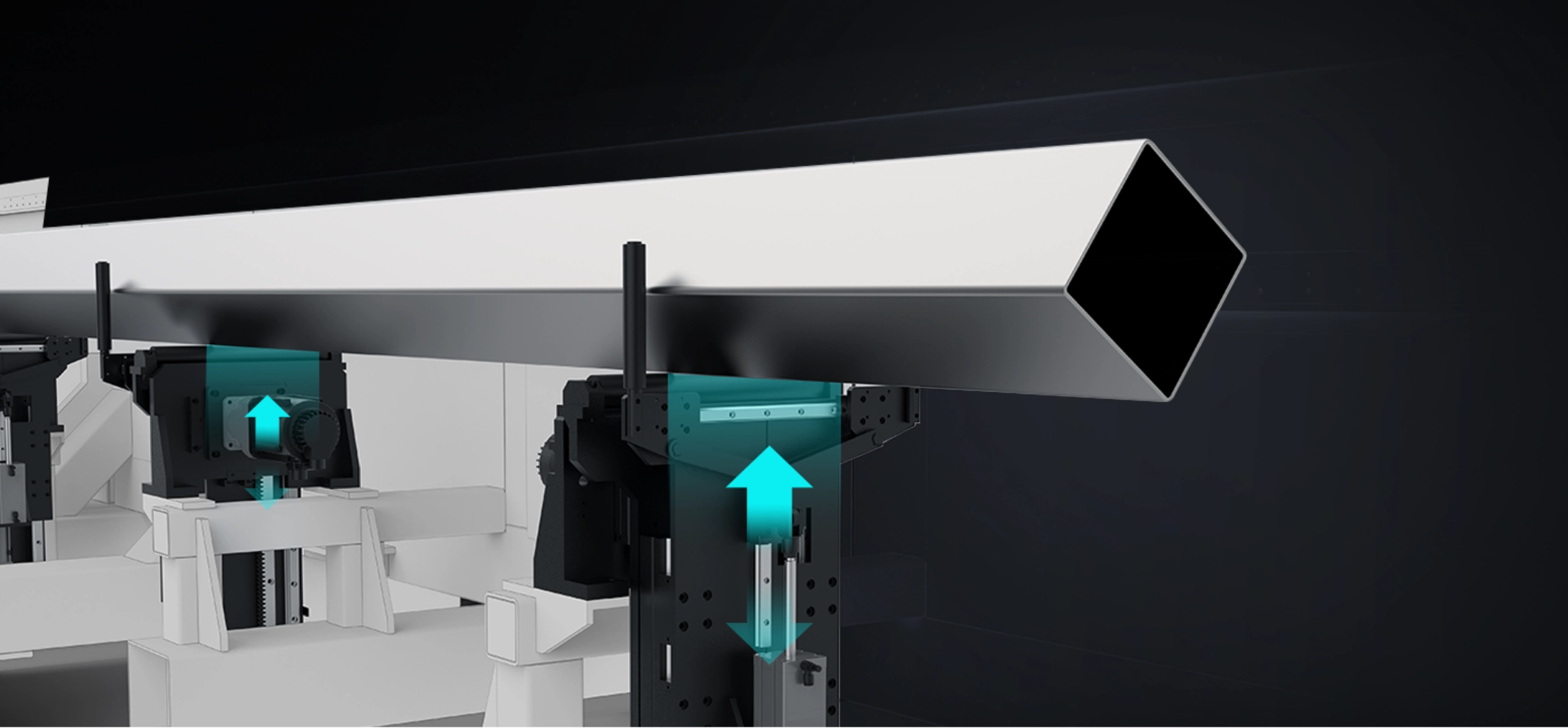

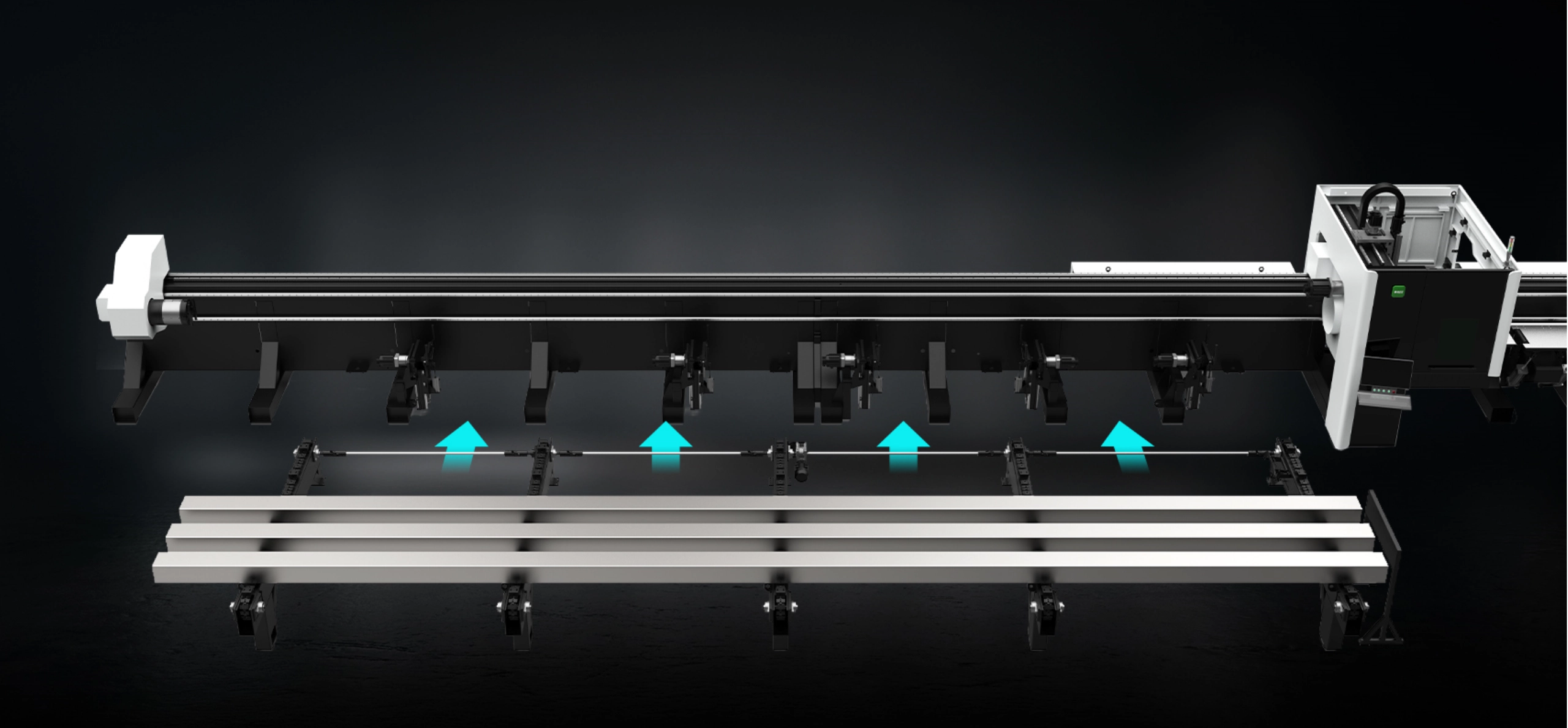

The intelligent follow-up support dynamically adjusts the support height in real time based on the cutting process. This prevents tube deflection or vibration during high-speed rotation, maintaining optimal tube alignment and ensuring consistent cutting accuracy and stability throughout the operation.

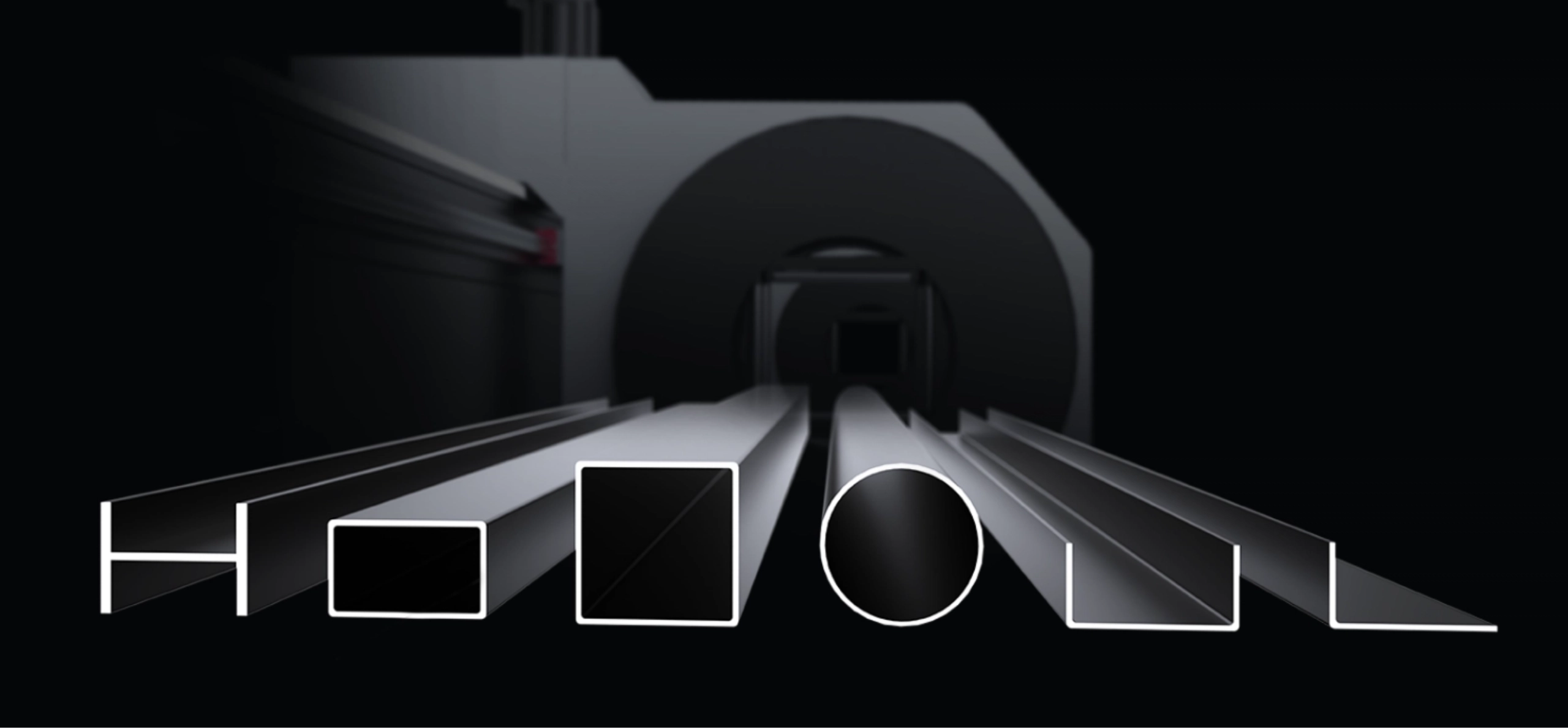

Capable of processing work-pieces up to 12 meters in length, the machine accommodates larger dimensions and supports both high-volume and customized production scenarios. With a tube diameter range of Ø20–350 mm, it handles a wide variety of specifications and materials—offering true multi-purpose functionality for flexible and efficient manufacturing.

Compatible with automated loading and unloading modules, it enables a fully automated workflow covering material loading, machining, and unloading. This reduces reliance on manual operations and enhances overall throughput.