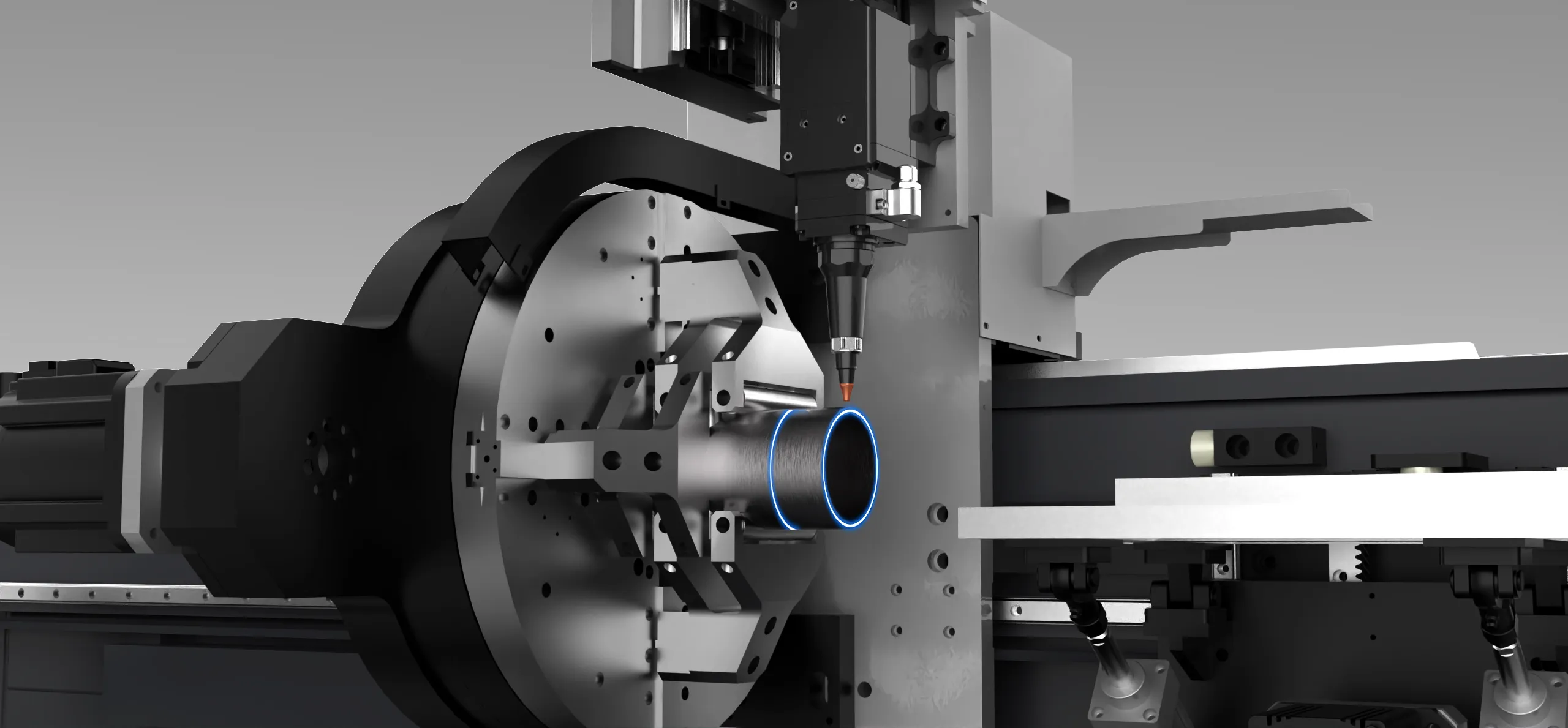

Dynamic Support, Precision Guaranteed

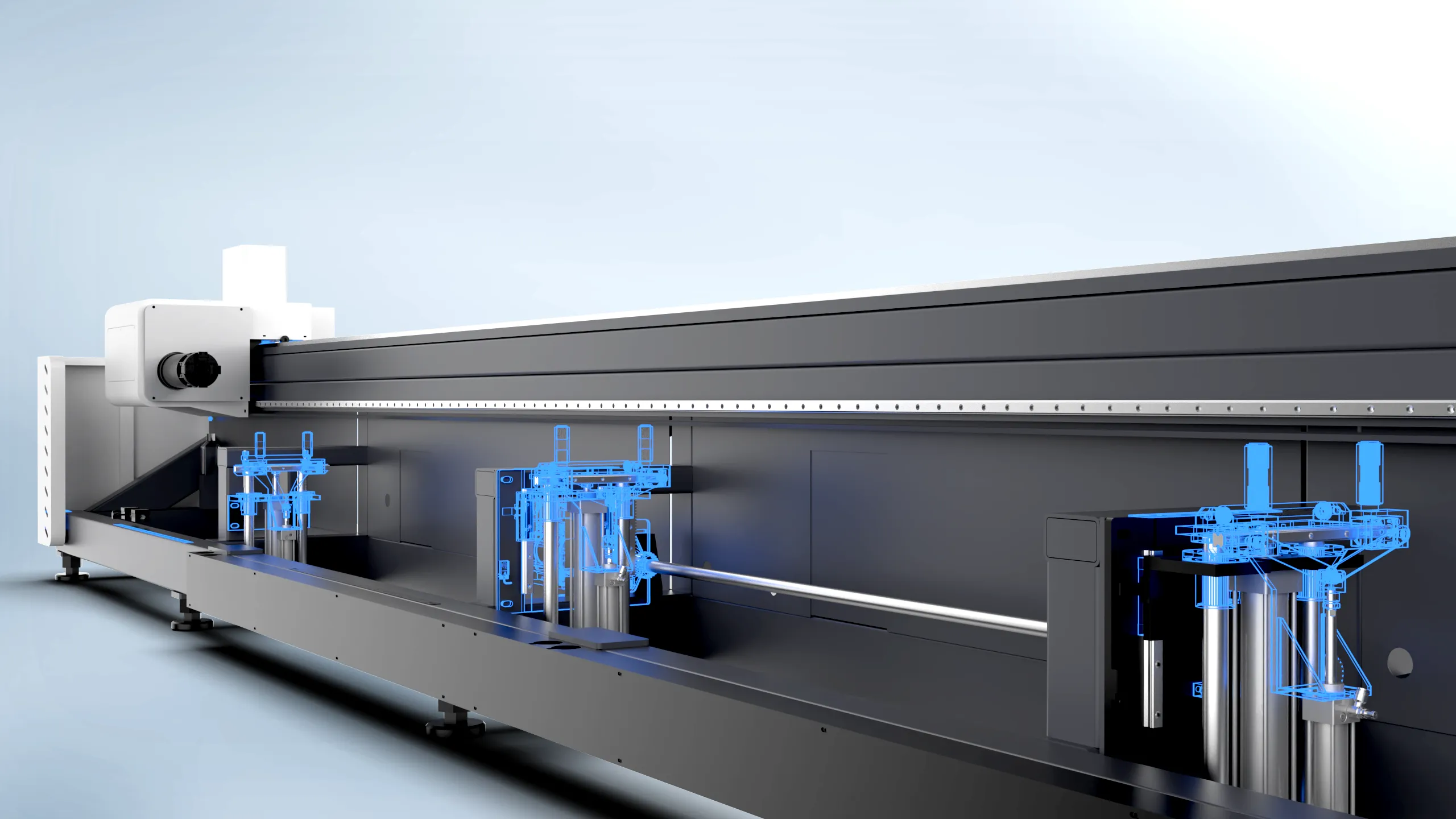

Minimal Tailing, Maximum Yield

Equipped with acceleration up to 2G and a high-speed chuck running at 200 r/min, the machine delivers exceptional dynamic responsiveness for ultra-fast tube cutting. It significantly shortens processing cycles, boosts production capacity, and empowers customers to deliver faster.

A dual support system, comprising adaptive and concave roller supports, effectively suppresses tube movement during high-speed operation. The stable cutting process ensures high-precision finished parts.

Metalworking

Office furniture

Guardrail manufacturing

Steel Structure

Sheet Metal Processing

| Model | V12 |

|---|---|

| Power | 1.5-3kW |

| Processing Diameter | Φ8-Φ120mm □8*8-□120*120mm |

| Max Load Capacity per Piece | 80kg |

| Processing Length | 6500mm |

| Maximum Acceleration | 2G |