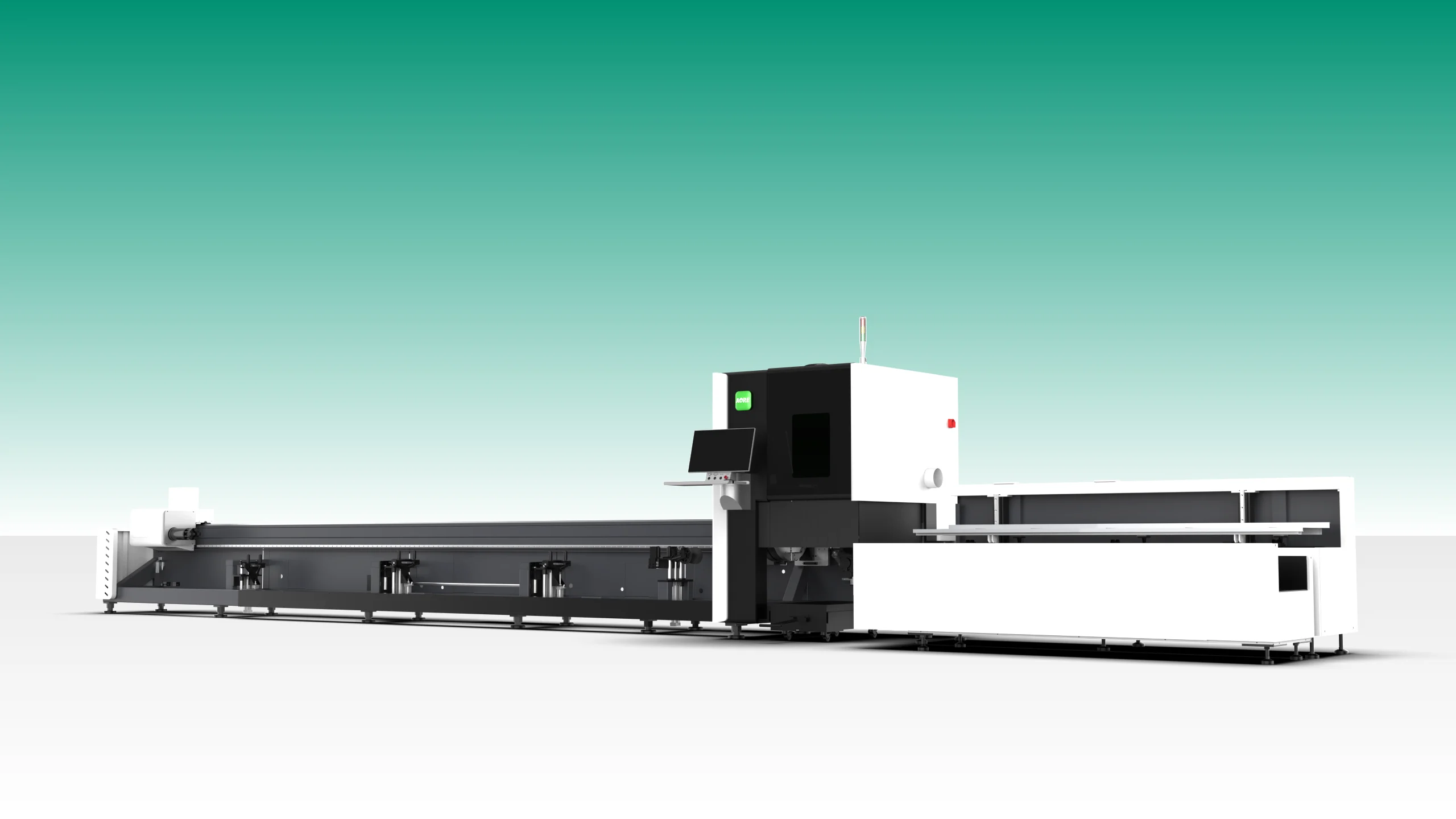

Ultra-Fast Cutting, Elevated Efficiency

Equipped with acceleration up to 2G and a high-speed chuck running at 200 r/min, the machine delivers exceptional dynamic responsiveness for ultra-fast tube cutting. It significantly shortens processing cycles, boosts production capacity, and empowers customers to deliver faster.

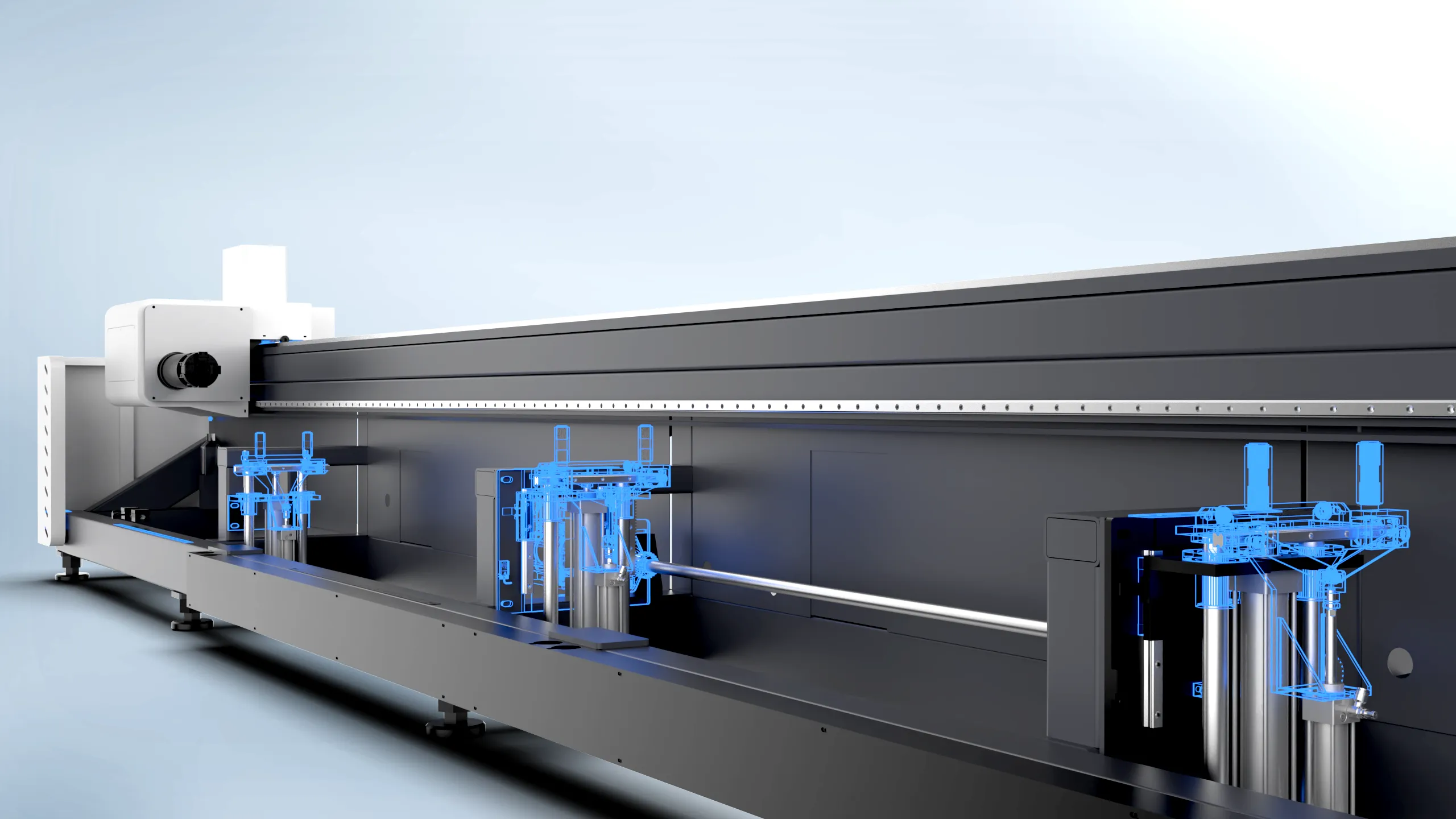

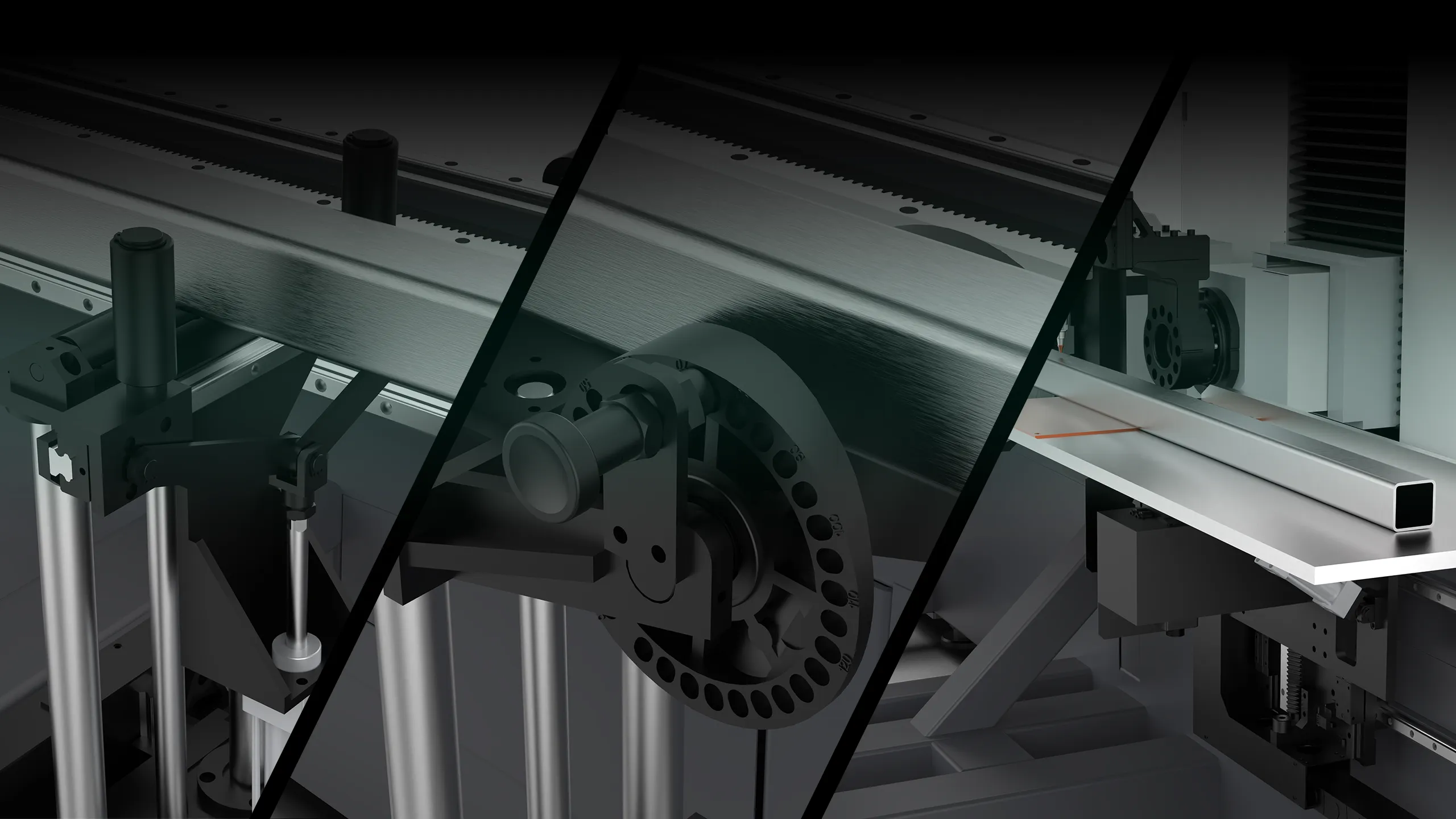

Intelligent Support, Precise Stability

A dual support system, comprising adaptive and concave roller supports, effectively suppresses tube movement during high-speed operation. The stable cutting process ensures high-precision finished parts.

Dynamic Support, Precision Guaranteed

From loading to unloading, the supports provides continuous, dynamic stability for long tubes. This ensures consistent cutting accuracy throughout the entire process, meeting the demands of high-standard applications.

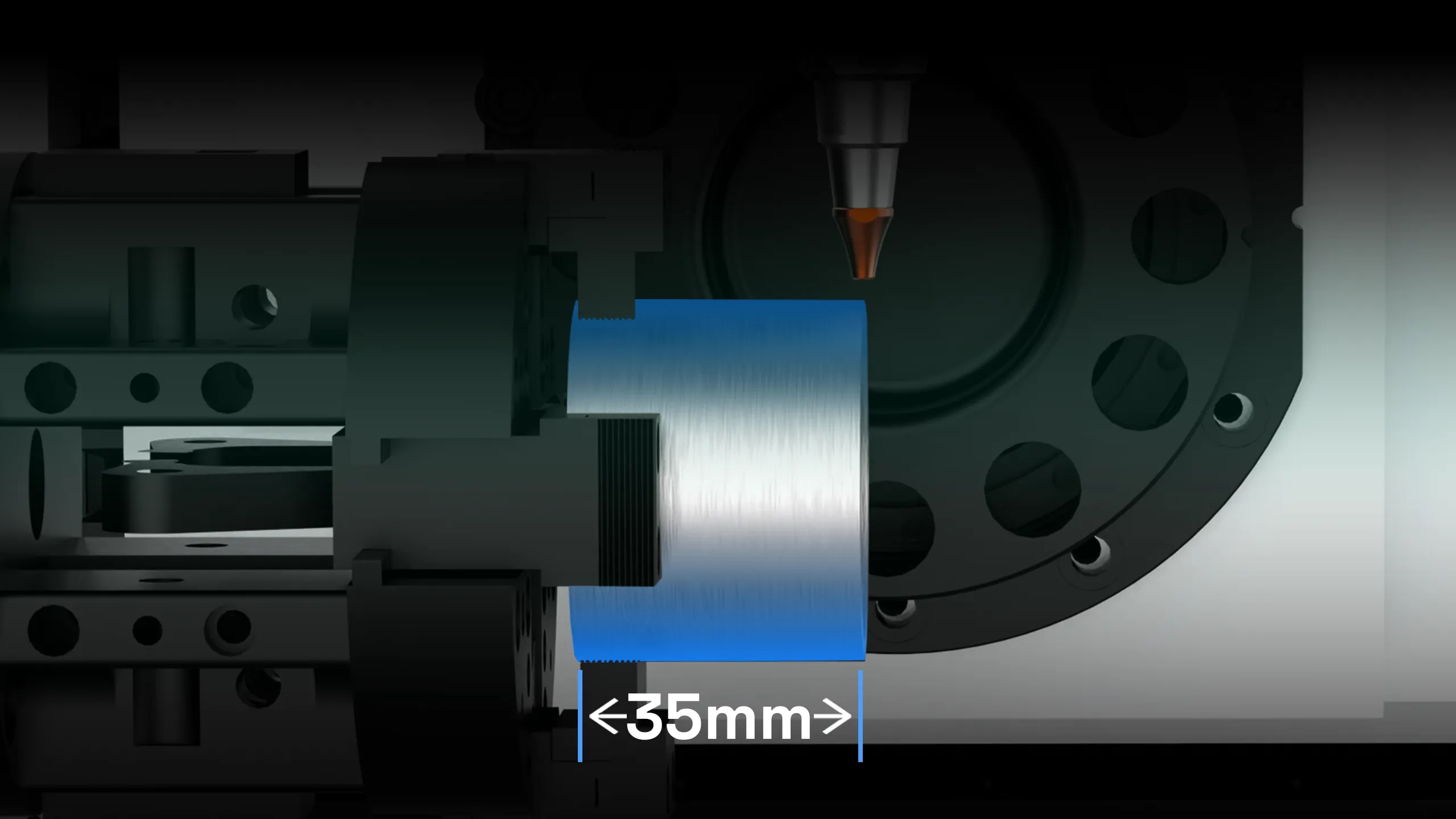

Minimal Tailing, Maximum Yield

With a front-shift chuck design, tailing length is precisely controlled, minimizing material waste. This not only extends the chuck’s lifespan by reducing wear but also improves overall production efficiency.

High-speed Cutting with Outstanding Performance

Boasting a maximum acceleration of 2G, a maximum chuck idle speed of 150m/min, and a maximum chuck rotation speed of 200r/min, the high-speed configuration delivers a leap-forward improvement in production efficiency and provides strong support for high-efficiency production

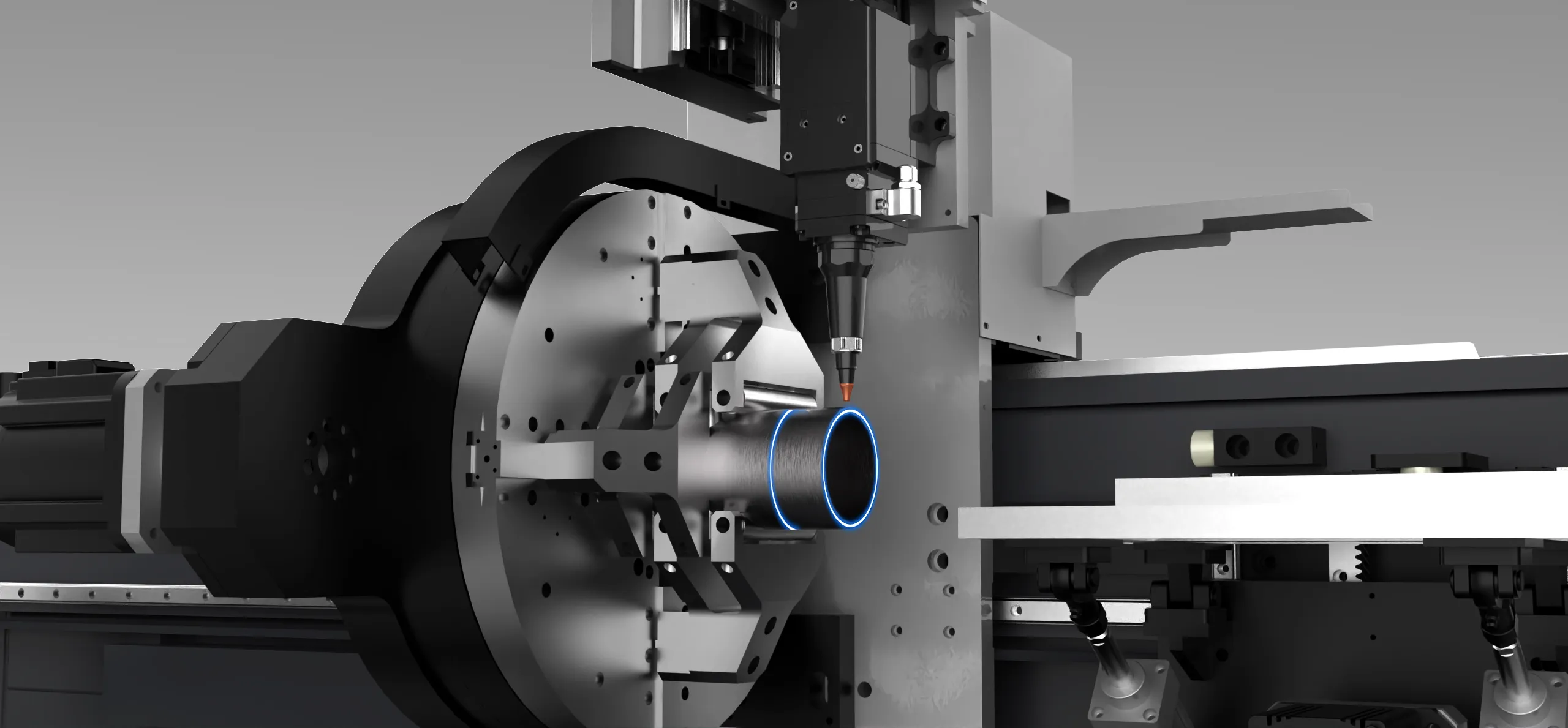

Front Chuck Displacement, Enhanced Performance

The servo-driven front chuck moves to position the laser head between the front and rear chucks during cutting. This setup ensures high precision for long workpieces and guarantees consistent end-product quality for our customers.

Intelligent No-Drawing Function, One-Click Processing

The built-in drawing-free operating system requires no manual drafting. Simply enter relevant parameters, and the system automatically generates 3D models, enabling one-click efficient processing tailored for industries such as guardrail manufacturing

±50° Bevel Cutting & Seamless Splicing

It enables ±50° bevel cutting of tubes. With the cutting nozzle located at the rotation center, higher cutting accuracy is achieved. There is no need for repeated tube feeding, preventing deformation of thin-walled tubes caused by repeated clamping and pulling, thus ensuring higher precision in small-diameter bevel cutting. It supports splicing of tubes at any angle, improving welding efficiency by 30%

Ultra-Short Remnant, Every Millimeter Counts

With a minimum remnant length of just 35mm, it significantly improves overall material utilization, effectively reduces costs, minimizes waste generation, and maximizes material value—providing solid support for enterprises in lowering costs and enhancing efficiency

Dual-Zone Intelligent Following, Unwavering Stability

The system features roller following support in the loading zone and tilting following support in the unloading zone. Servo-based intelligent control ensures dynamic support throughout the entire tube processing cycle, guaranteeing consistently high machining accuracy.

Applications

Metalworking

Office furniture

Guardrail manufacturing

Steel Structure

Sheet Metal Processing

Technical Parameters

| Model | V12 | V12 Pro |

|---|---|---|

| Power | 1.5-3kW | 1.5-3kW |

| Processing Diameter | Φ8-Φ120mm □8*8-□120*120mm | Φ20-Φ120mm □20*20-□120*120mm |

| Max Load Capacity per Piece | 80kg | 80kg |

| Processing Length | 6500mm | 6500mm |

| Maximum Acceleration | 2G | 2G |