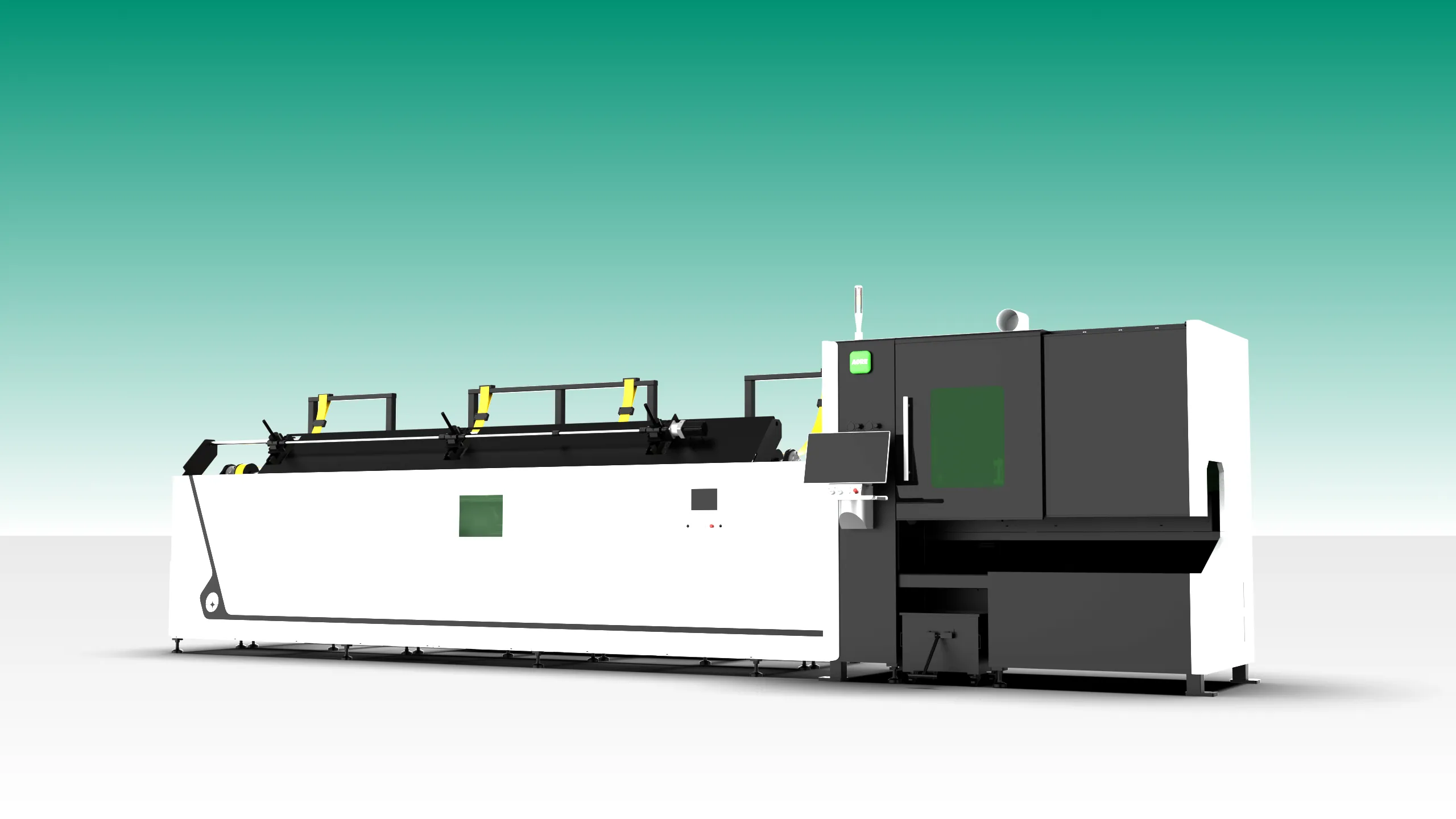

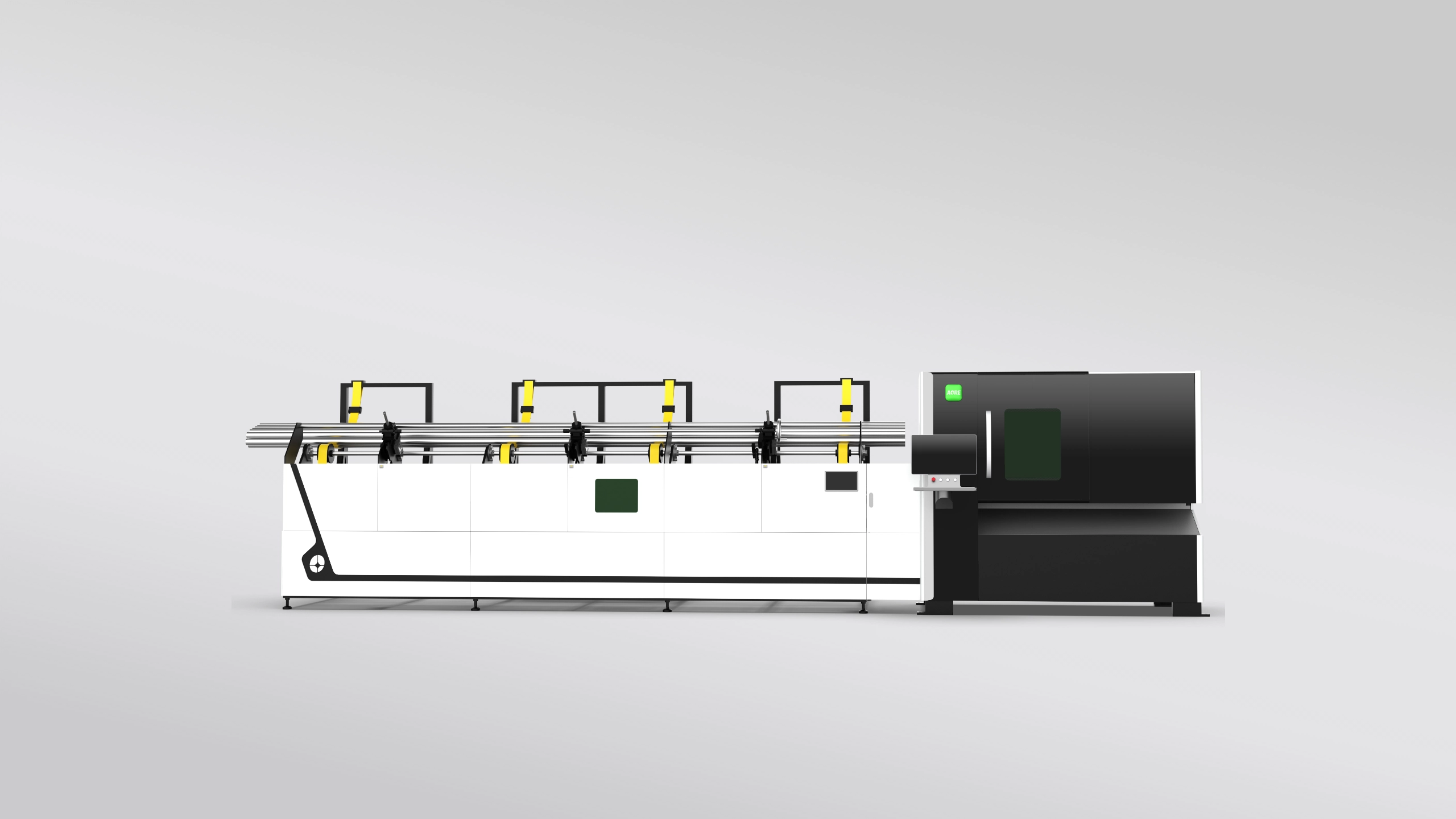

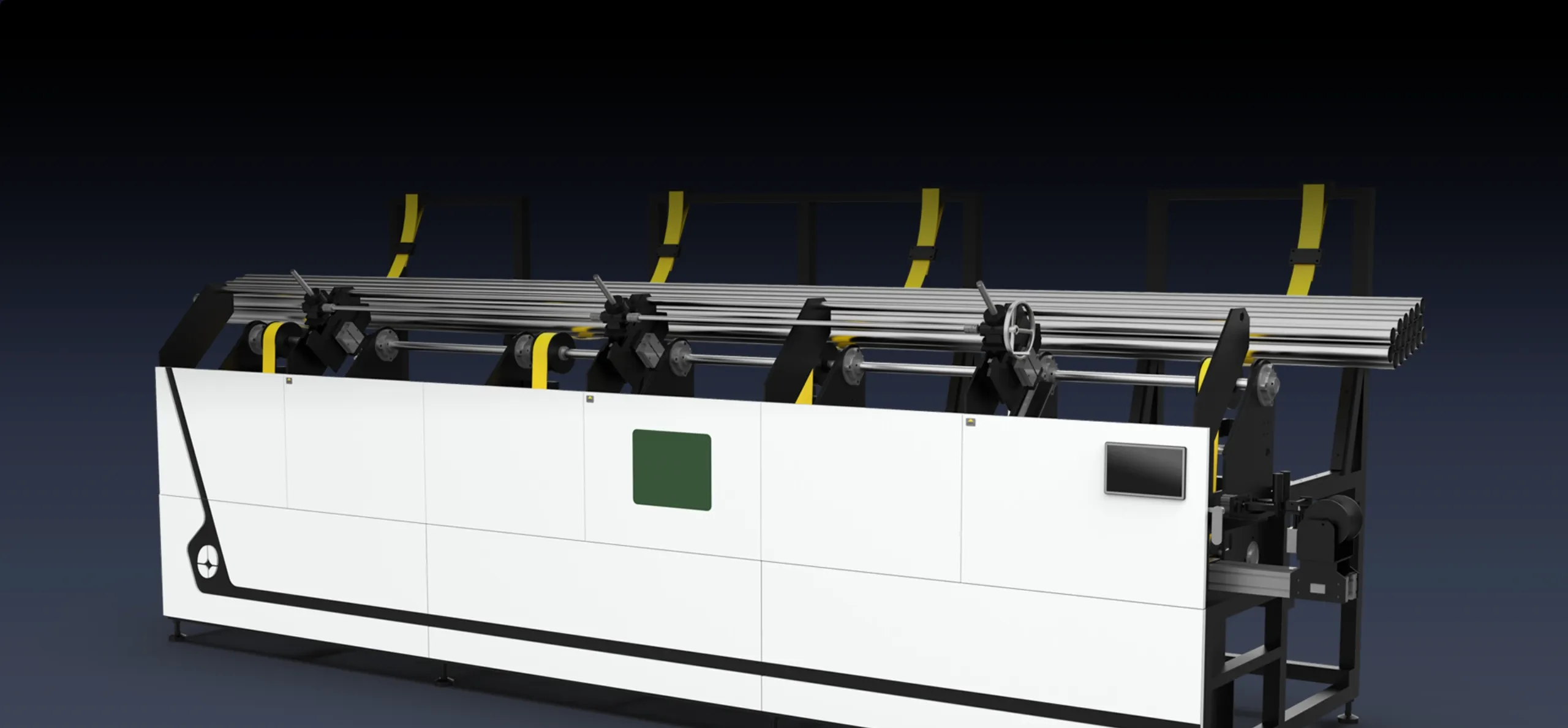

Compact Structure

Small footprint design that saves valuable floor space

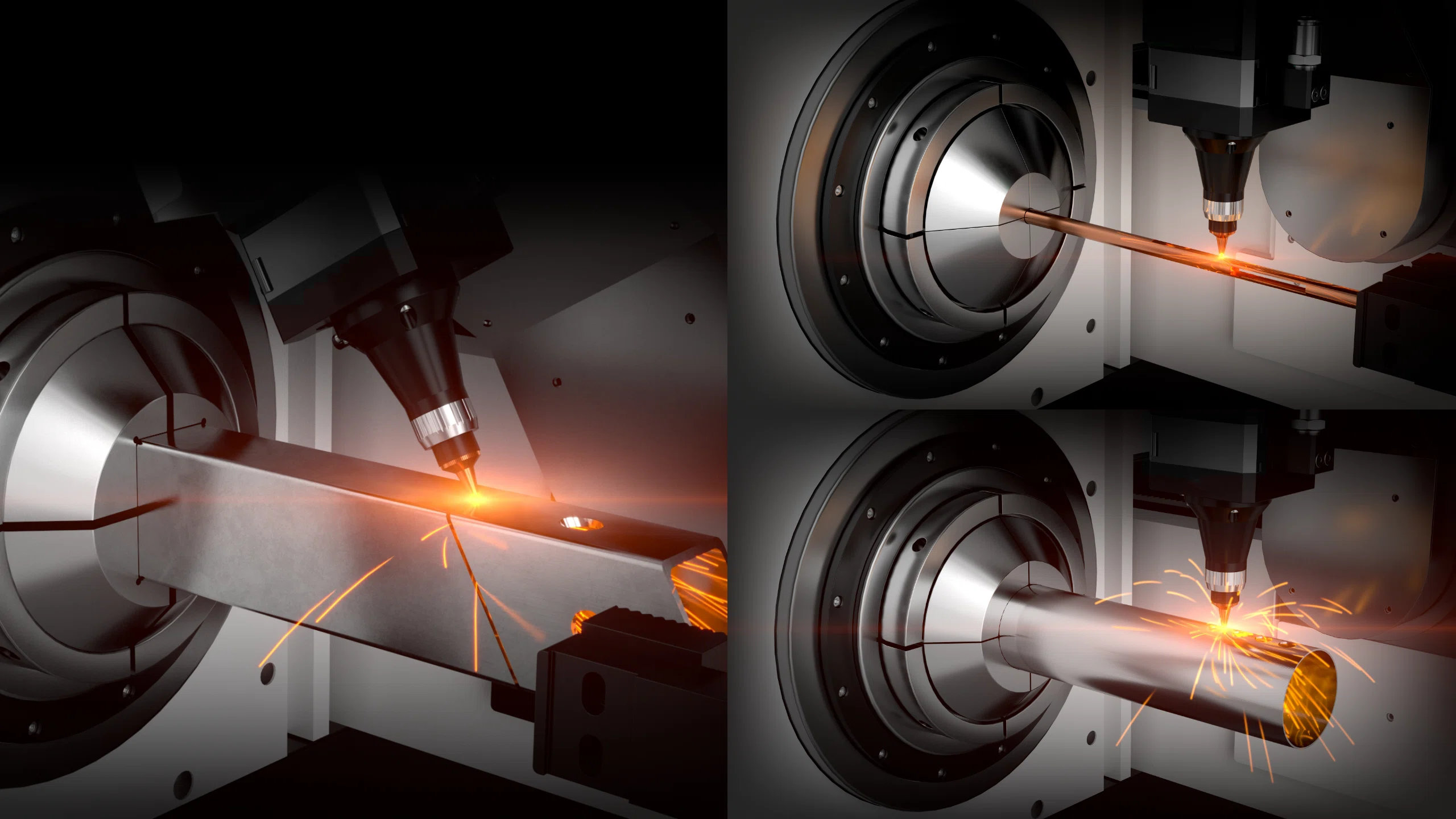

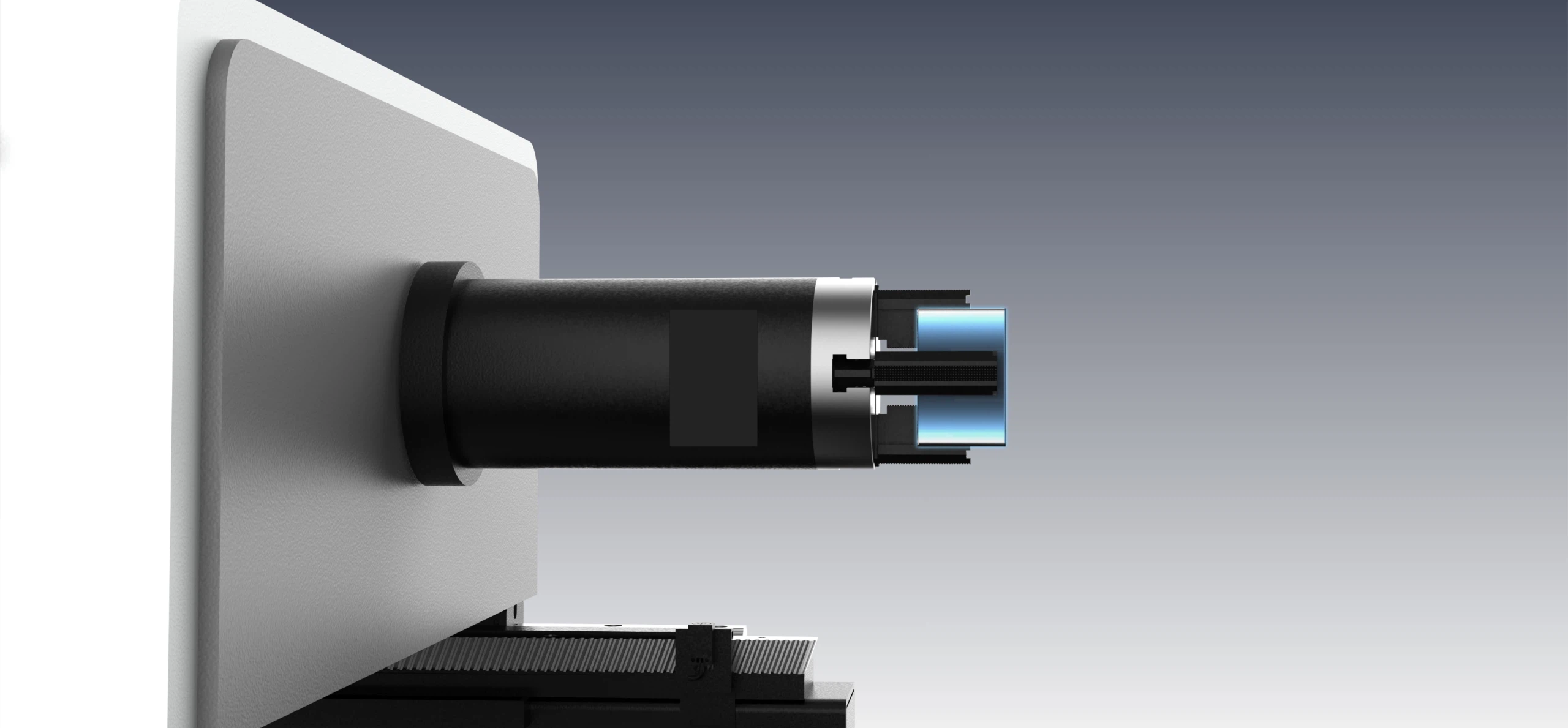

Chuck Clamping

Enables fast and precise cutting of small-diameter tubes in various shapes, including round, square, and oval profiles

High-Power Laser Source

Delivers high-speed, high-precision cutting performance for demanding tube processing tasks.

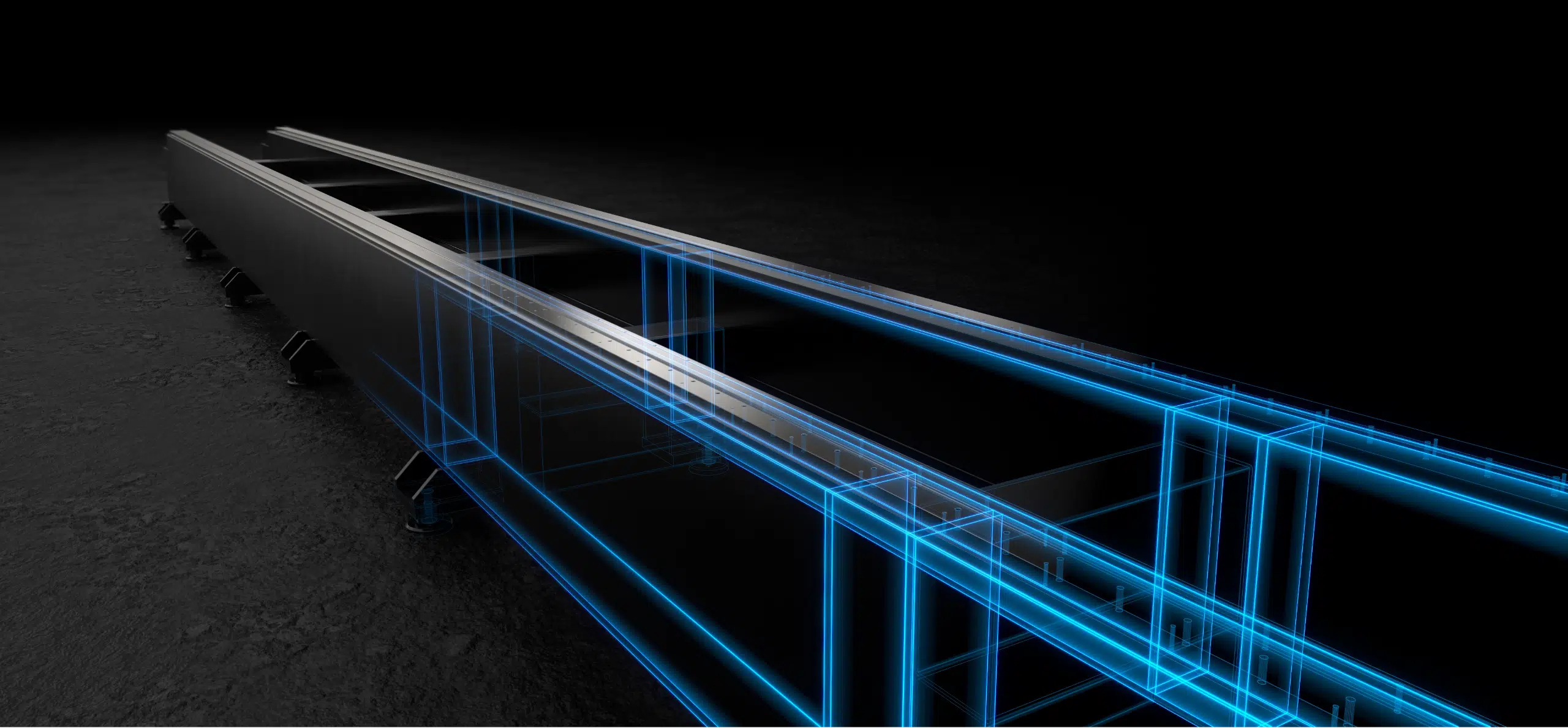

High-Rigidity Bed Structure

Horizontal twin-beam design with self-grinding stops ensures heavy-duty stability and enhanced cutting rigidity at high speeds.

Short Tail Cutting

Tail length can be reduced to as little as 80mm, maximizing material usage and minimizing production costs.

Standard Pneumatic Chuck

Equipped with a high-speed pneumatic chuck optimized for small-diameter tubes, offering strong clamping force, fast response, and rotational speeds up to 180 rpm for stable, efficient cutting.

Smart and Efficient Loading

Supports automated batch loading of small tubes, minimizing manual intervention and increasing continuous processing efficiency.

Applications

Furniture Manufacturing

Fitness Equipment

Medical

Steel Structure

Sheet Metal Processing

Technical Parameters

| Model | TM120 |

|---|---|

| Power | 1.5-3kW |

| Processing Diameter | Φ15-Φ100mm □15*15□70*70mm |

| Max Load Capacity per Piece | 100kg |

| Processing Length | 5000~7000mm |

| Maximum Acceleration | 1.5G |