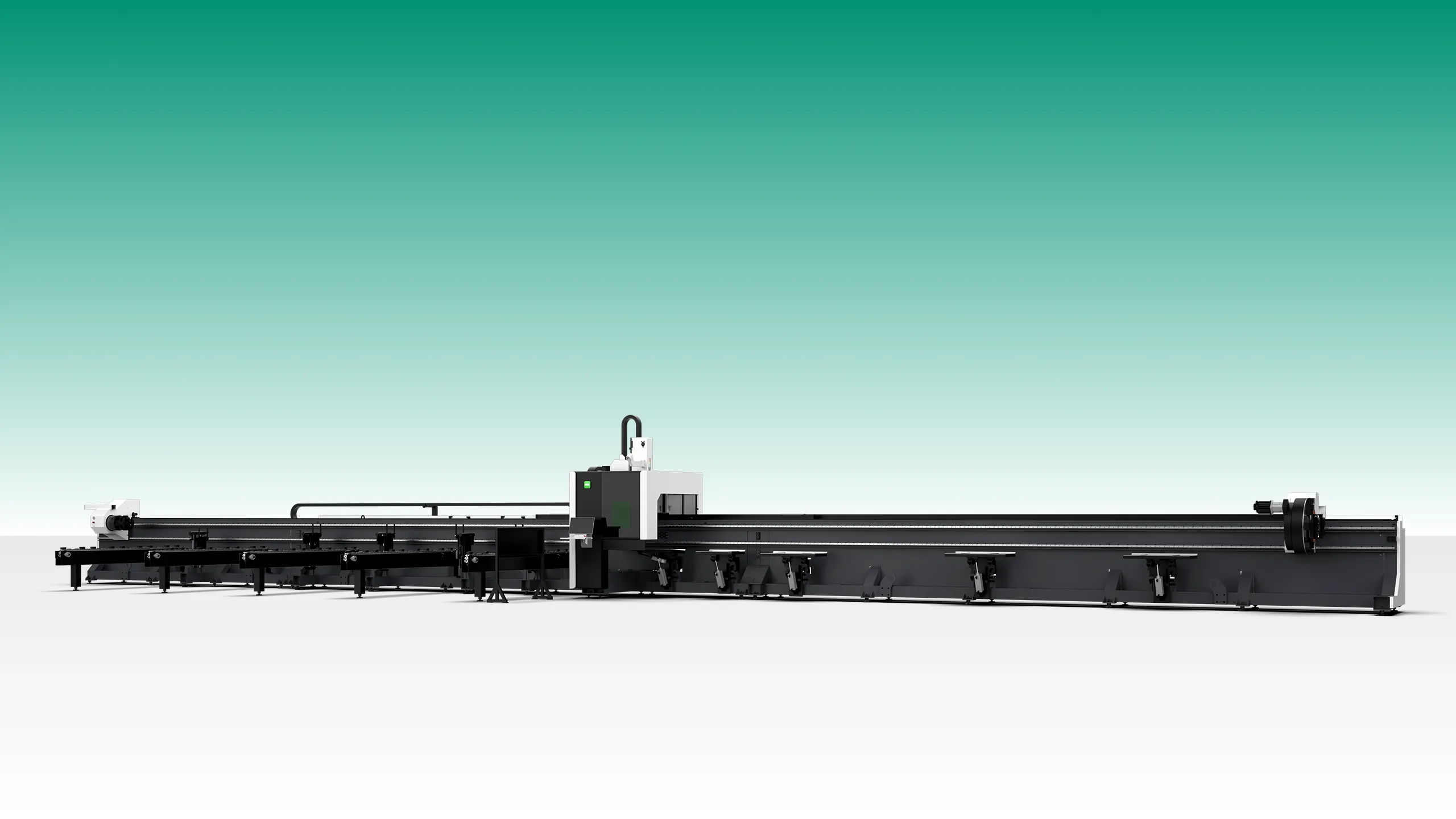

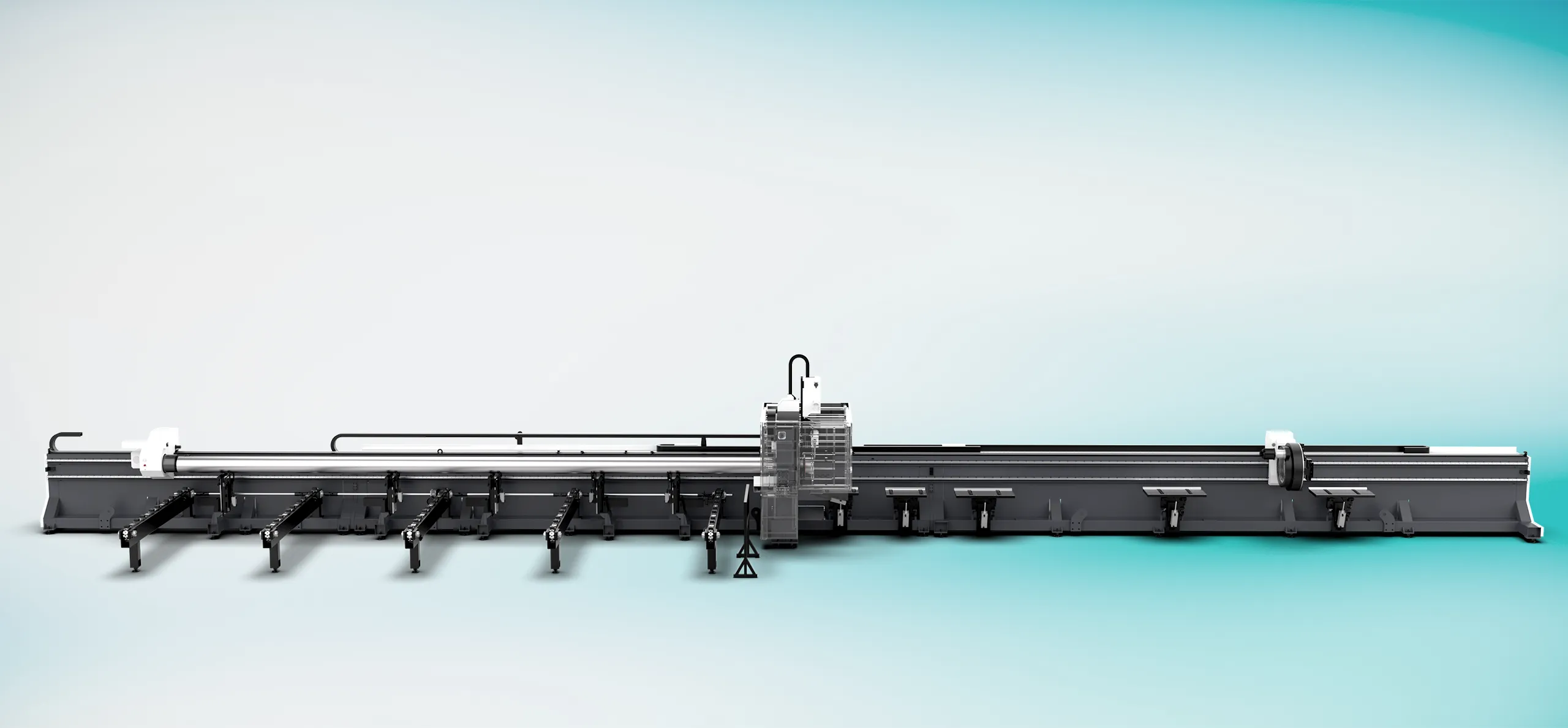

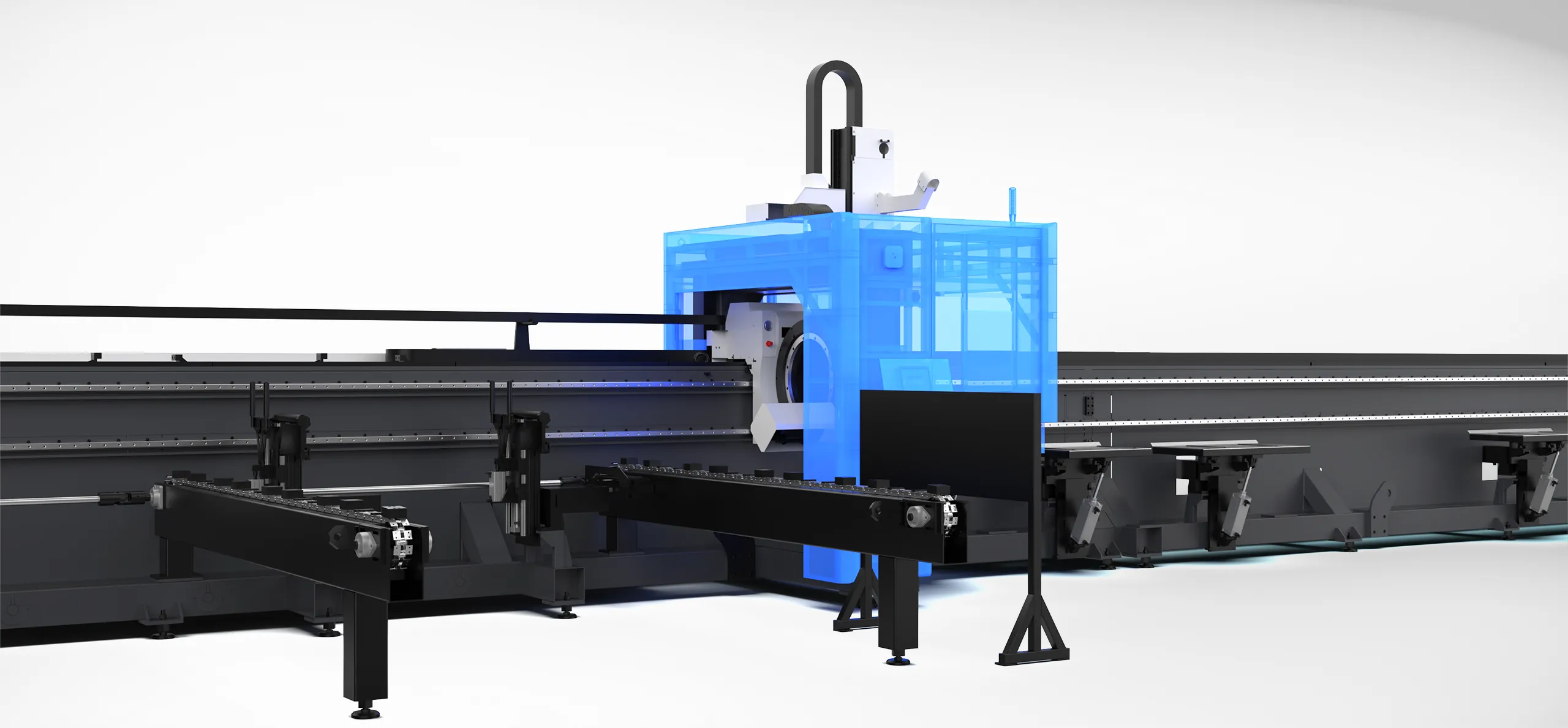

Efficient Loading & Unloading, Time-Saving Operation

Seamlessly integrates loading and unloading, preloading, and servo-driven following-up support for dynamic continuous processing. Minimizes downtime, enhances cutting precision, and maximizes overall productivity.

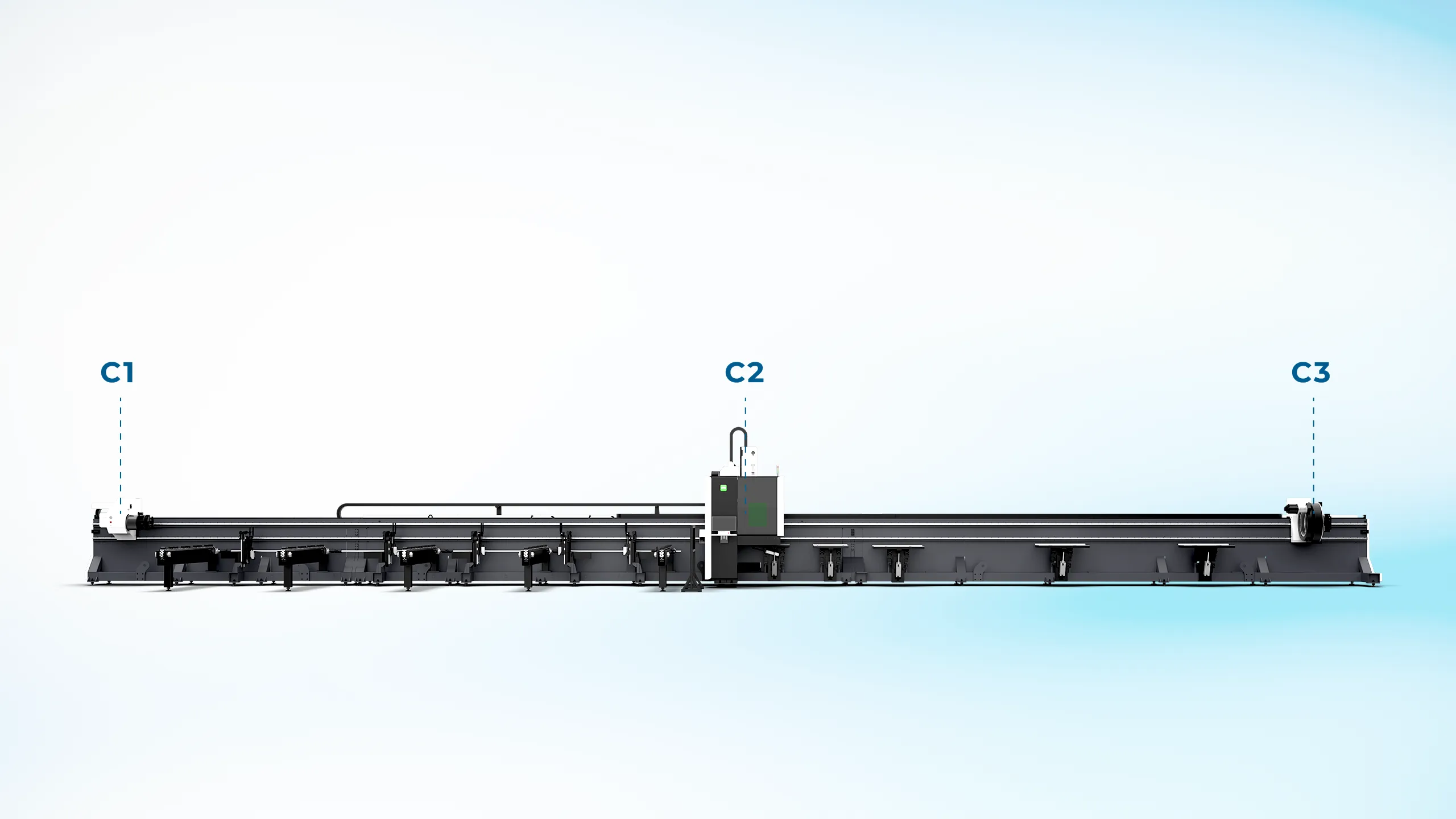

Three-Chuck Design for Stable & Efficient Cutting

The three-chuck design delivers vibration-free, full-length stable clamping, and supports both full-length and segmented cutting, with an efficient third chuck enabling material reversal to boost processing speed and product quality.

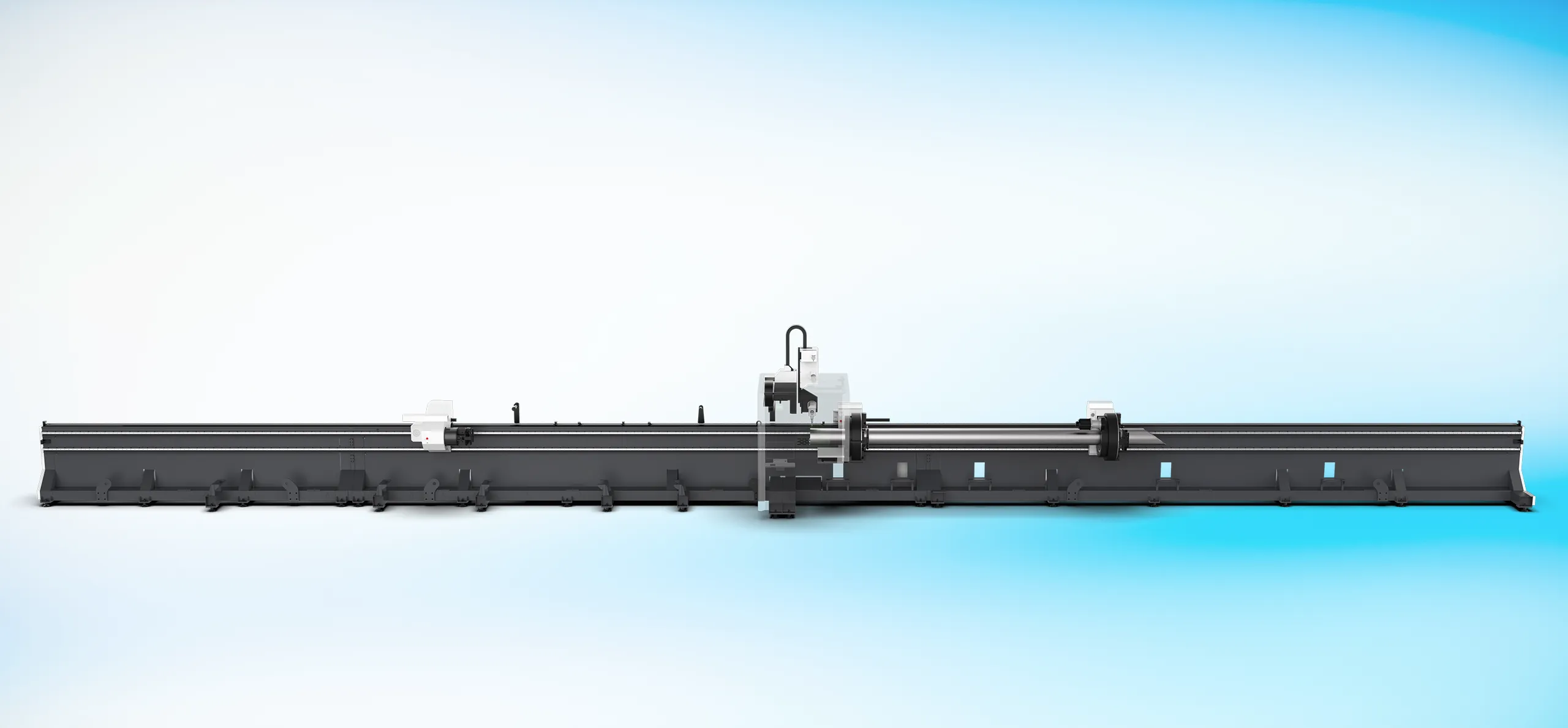

Intelligent Control with Precision and Stability

Combines advanced auto-centering, tube detection, intelligent autofocus, and closed-loop control to ensure precise positioning and stable operation, delivering consistent high-quality results across complex multi-material cutting.

Zero Tailing for High-Efficiency Production

Innovative zero tailing cutting technology maximizes material utilization and empowers sustainable, high-efficiency production.

Double/Three Chuck Switching, Flexible Processing

During operation, the third chuck remains in standby position without engaging in motion, maximizing overall processing efficiency.

Fully-Enclosed Safety System, Long-Lasting Reliability

Features temperature management, automatic lubrication, and fully enclosed safety systems to guarantee safe, stable operation under varied conditions, extend equipment lifespan, and support efficient, continuous production.

Applications

Construction Steel Structure

Engineering machinery

Shipbuilding

Fitness Equipment

Agricultural Machinery

Technical Parameters

| Model | M28 | M36 | M52 |

|---|---|---|---|

| Power | 6-12kW | 6-12kW | 6-12kW |

| Processing Diameter | Φ20-Φ280mm □20*20-□280*280mm | Φ20-Φ360mm □20*20-□360*360mm | Φ20-Φ360mm □20*20-□360*360mm |

| Max Load Capacity per Piece | 500kg | 1200kg | 2500kg |

| Processing Length | 12000mm | 12000mm | 12000mm |

| Maximum Acceleration | 1G | 0.8G | 0.3G |