How to clean industrial laser cutting machine laser lenses?

2025-04-27

Unstable cutting performance of fiber cutting laser machine? Dirty internal lenses could be sabotaging your industrial laser cutting precision! This essential maintenance guide reveals 3 professional troubleshooting methods to diagnose and solve lens contamination problems. Learn how to solve:

1.Quickly test lens cleanliness using the simple white paper method

2.Systematic inspection of protective lenses (upper/lower/middle lenses)

3.Check for contamination sources between the fiber head and laser head

We break down complex optical maintenance tasks into actionable steps and provide key preventive measures recommended by manufacturers. Protect your equipment investment and maintain peak cutting performance with these proven industrial laser maintenance strategies!

Problem description:

To confirm whether the industrial laser cutting machine internal lens of the laser head is clean, you can place white paper under the laser head to check whether there are dirty spots to determine the condition of the internal lens.

Problem cause analysis:

By observing the red light state, you can determine whether the internal lens of the industrial laser cutting machine laser head is clean or abnormal. However, if you need to confirm which specific lens is damaged, you need to disassemble it separately for confirmation.

Solution:

1. Check the upper or lower protective mirror of the industrial laser cutting machine:

According to the instructions and in accordance with the standard operation, remove the upper and lower protective mirrors. If you find that the fiber cutting laser machine protective lens has dirty spots, you need to use anhydrous alcohol and dust-free cotton swabs to gently wipe it in one direction. If it cannot be wiped clean, you need to replace a new lens.

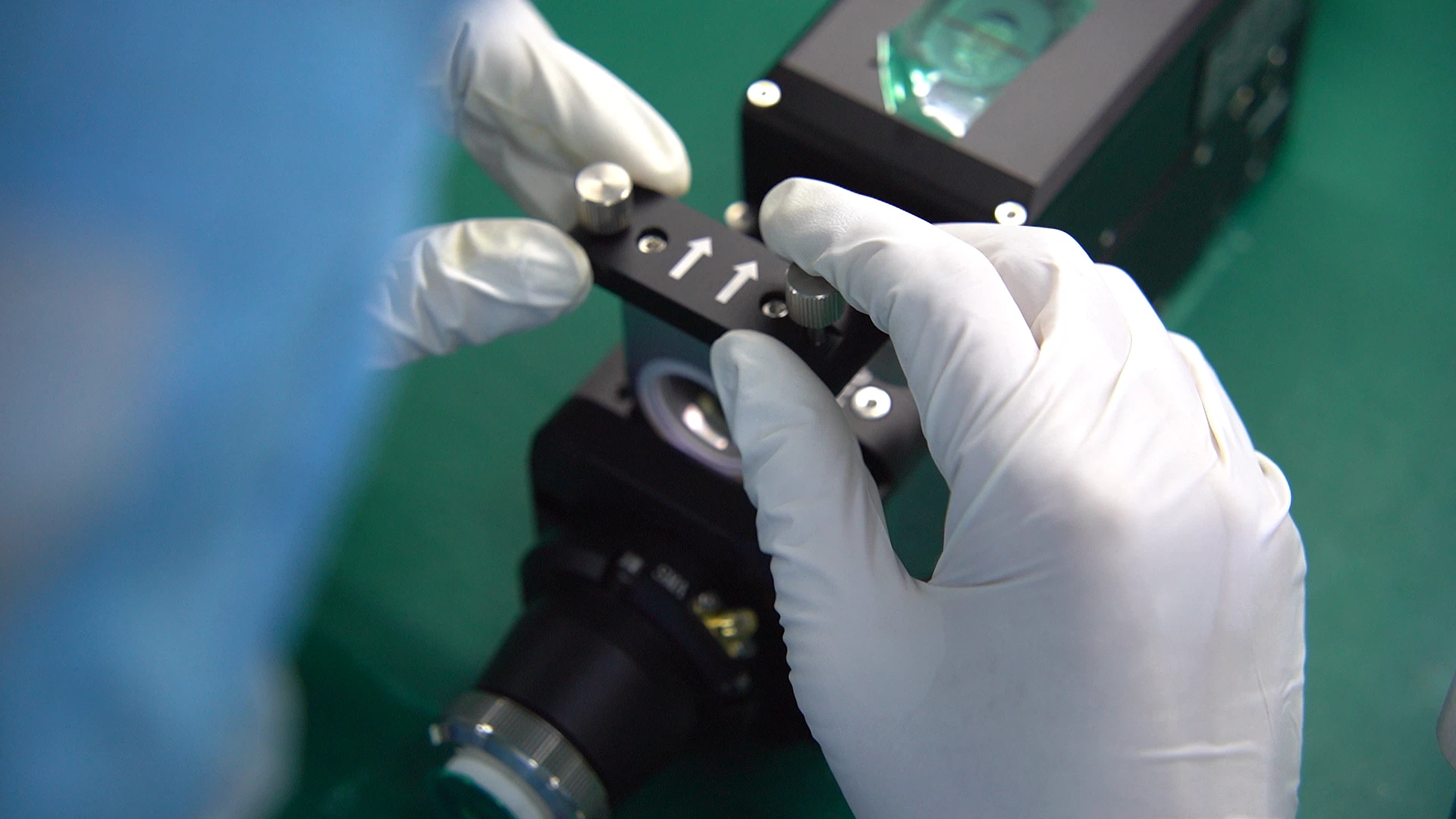

2.Check the focusing protection lens of the fiber cutting laser machine (middle protective mirror):

If the dirty spots still exist after the upper and lower protective lenses are replaced as mentioned above, you need to give priority to checking the status of the middle protective lens. Without disassembling the laser head, you can remove the nozzle and ceramic ring of the laser head, observe the condition of the internal lens of the laser head from the bottom of the laser head, and quickly determine whether it is a problem with the fiber cutting laser machine middle protective connection. If it is confirmed that the protective lens is damaged, you need to clean or replace the lens according to the video specifications.

3. Separate the industrial laser cutting machine fiber head and laser head for inspection

If the black spot still exists after the above lens is replaced, you need to separate the fiber head and the laser head, check them separately, and determine the specific source of the dirty spot.

By placing the laser head horizontally, facing the glasses at one end of the laser head, and using a flashlight to illuminate the light at the other end, observe the inside. If it is confirmed that the dirty spot comes from the laser head, you need to contact the fiber cutting laser machine manufacturer's engineer. With knowledge, remove the anti-tear label and disassemble the inside of the laser head for inspection, and check the focusing lens group and the collimating lens group in turn. And clean the lens according to the specifications. If the lens cannot be wiped clean, it needs to be replaced.