Applications of Laser Tube Cutting Machines - Fitness Equipment Industry

2025-12-16

To address core challenges in the fitness equipment manufacturing sector—including inefficiency, material waste, inconsistent quality, and environmental compliance issues, laser tube cutting technology offers a revolutionary solution. With its flexible production methods, high precision, stable cutting performance, and clean process flow, laser cutting technology enhances product quality and sustainability. The next-generation intelligent heavy-duty tube laser cutting machine takes this further by integrating automated loading/unloading, a four-chuck stabilization system, and a smart control system. This not only enables highly efficient production but also empowers manufacturers to enhance their market competitiveness through superior cutting technology.

I. Outdated Traditional Processing Solutions

While the fitness equipment industry thrives, manufacturers face numerous challenges that constrain their development. One such challenge is the obsolescence of traditional processing solutions.

First, outdated traditional processing equipment not only has limited functionality but also a short service life, thereby increasing operational costs for fitness equipment manufacturers. Second, these machines exhibit low cutting precision and poor material utilization, resulting in significant material waste during processing.

Additionally, the production process generates substantial smoke and dust, causing severe environmental pollution.

II. Advanced tube Laser cutting machine Technology

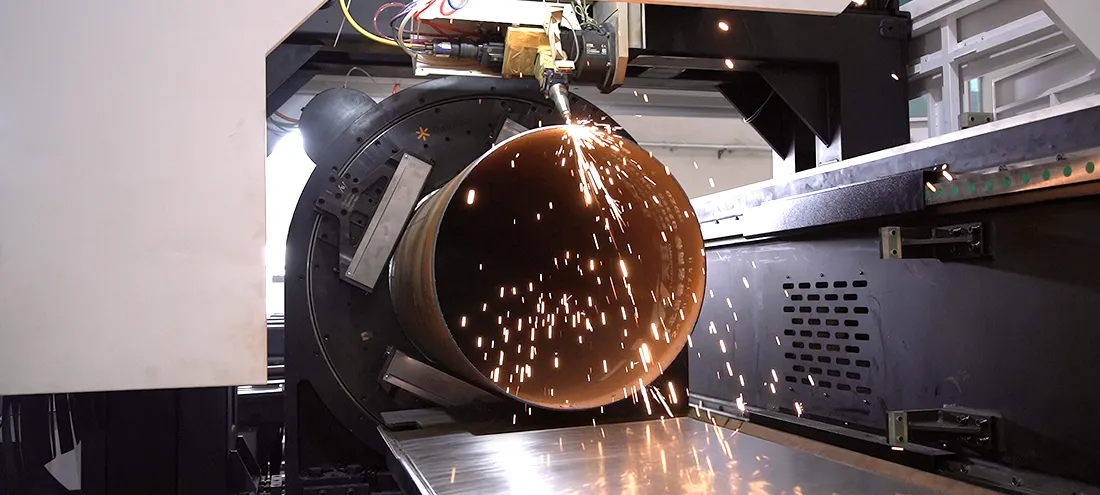

Today, with the continuous advancement of laser cutting technology, an increasing number of manufacturers are adopting CNC tube laser cutters for processing. Laser cutting offers a more efficient solution to the shortcomings of traditional processing methods in the fitness equipment industry.

1. High efficiency of laser tube cutting machine

In tube processing, laser cutting technology offers exceptional efficiency. Compared to conventional mechanical cutting methods, laser cutting eliminates the need for additional tools and molds. Cutting is achieved simply by adjusting laser beam parameters, enabling batch production. This not only reduces production time and costs but also enhances efficiency.

2. The tube laser cutting machine has high cutting precision.

High cutting precision represents a major advantage of the CNC tube laser cutter. Laser cutting uses a high-energy laser beam to achieve high-precision processing of tubular materials. Laser cutting consistently meets stringent requirements for both dimensional accuracy and precision, ensuring the manufacturing quality of fitness equipment.

3. Flexible, environmentally friendly, and sustainable

Pipe laser cutting machine offers flexibility and environmental sustainability. It cuts across all pipe materials, including stainless steel and aluminum alloy, without restrictions. Moreover, it effortlessly achieves complex shapes to meet diverse fitness equipment requirements. The process generates no harmful emissions or waste liquids, reduces environmental pollution, and enhances eco-friendliness.

4. High cutting quality and low maintenance cost

laser cutting guarantees superior processing quality and surface finish. Due to the extremely small heat-affected zone of laser cutting, deformation and damage to the tubing are minimized, ensuring dimensional stability and shape integrity. Additionally, laser cutting eliminates tool wear and cutting forces, preventing surface damage to tubes. Therefore, tubes processed via laser cutting exhibit superior machining quality and surface finish, reducing subsequent maintenance and repair costs.

In summary, within the field of tubular material processing, fiber laser tube cutting machine offers advantages including high efficiency, exceptional precision, superior processing and surface quality, flexibility, and environmental sustainability.

Ⅲ. About Aore Laser Fiber Laser Cutting Machine for tubes Solutions

For fitness equipment manufacturers prioritizing efficiency and quality, we recommend the following machine. It not only excels in precision and quality but also achieves more intelligent cutting capabilities.

Efficient Loading/Unloading for Time Savings:

Seamlessly integrates loading/unloading, pre-loading, and servo-driven post-support functions to enable dynamic continuous processing. Minimizes downtime while maximizing overall production efficiency.

Four-Chuck Design for Stable, Efficient Cutting:

The Four-Chuck fiber laser tube cutting machine design ensures vibration-free, full-length stable clamping, supporting both full-length and segmented cutting, enhancing processing speed and product quality.

Intelligent control for precision and stability: Combines advanced auto-centering, tube detection, intelligent autofocus, and closed-loop control to ensure precise positioning and stable operation, delivering consistent high-quality results across complex multi-material cutting for fitness equipment.

Full-Length Support for Accurate Cutting

The intelligent follow-up support system adjusts lifting height in real-time to prevent tube vibration and sagging, ensuring stable cutting and improved precision and product quality.

Engineered for Heavy-Duty Tube Cutting:

Equipped with a high-strength four-chuck system, the TZ Series pipe laser cutting machine delivers exceptional load capacity, firm clamping, and wide material compatibility—ideal for processing large-diameter, thick-walled tubes with ease

In the face of intense market competition, cutting precision has become a critical factor. Laser tube cutting machines can rapidly respond to market changes, helping you produce higher-quality fitness equipment such as treadmills and elliptical trainers. If you have any questions about the application of fiber laser tube cutting machines in the fitness equipment industry, or require further information regarding model selection, technical support, or services, please feel free to contact us. Explore advanced laser cutting solutions today to inject new competitiveness into your factory.