Fiber Laser Cutting Machines: Are They Worth It?

2025-06-07

In the highly competitive manufacturing industry, efficiency, precision and cost control are the key to laser cutting machine manufacturers' success. Laser cutting technology is becoming the preferred solution in the field of metal processing with its revolutionary advantages. The following are the significant values that choosing a high precision cnc fiber laser cutter brings to the company:

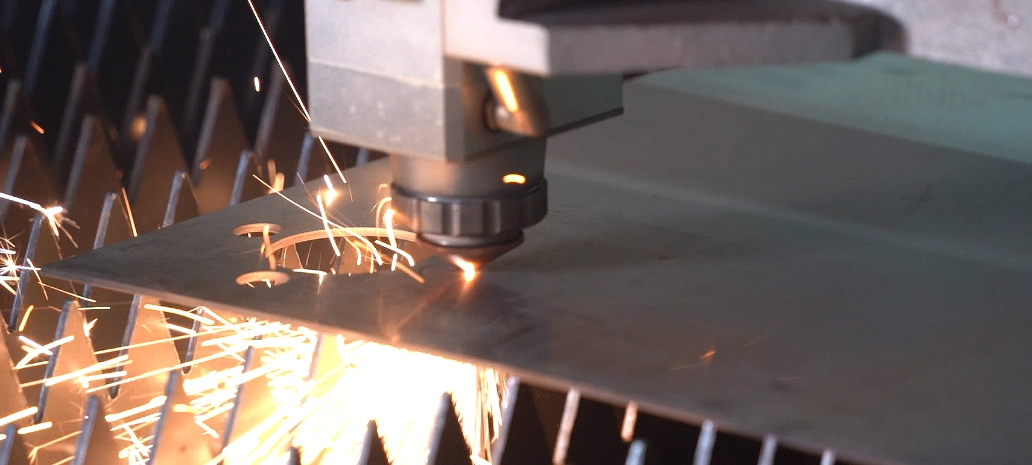

Precision and excellent cutting quality of Fiber laser cutting machines

Precision to the micron level:

The laser beam can achieve extremely fine focus, easily cutting complex graphics, small holes and sharp corners with minimal deviation.

Smooth burr-free edges:

cnc fiber laser cutter use high-energy lasers to melt or vaporize materials to form smooth, high-quality cutting edges, significantly reducing or even eliminating secondary processing (such as grinding and deburring), directly improving the aesthetics and functionality of products.

Low material loss:

Precise energy control greatly reduces the risk of material deformation, which is especially important for thin plate or precision parts processing.

Fiber optic laser cutting machine has strong adaptability and processing flexibility

Wide application:

Fiber optic laser cutting machines can efficiently process various metals (carbon steel, stainless steel, aluminum, brass, copper), and one machine can meet the needs of multiple materials.

Flexible processing:

It can switch different patterns instantly to achieve small batch customized production or complex prototype production without changing molds, accelerating product iteration.

CNC fiber laser cutter Excellent production efficiency and speed

High-speed cutting:

Laser cutting speed far exceeds traditional mechanical cutting (such as plasma and water jet), especially in thin plate processing, which greatly shortens the production cycle.

Automation:

Easily integrate automatic loading/unloading systems to achieve unmanned production, maximize equipment utilization, and reduce labor costs.

Quick start and stop:

The laser switch responds quickly and has no physical inertia. After optimizing path planning, it can further improve overall efficiency.

Cost-effectiveness and return on investment

Reduced operating costs:

Reduced secondary processing: High-quality cutting results save time and cost of subsequent processing steps.

Optimized material utilization: Advanced nesting software arranges parts tightly, maximizes material utilization, and reduces expensive metal waste.

Reduced loss and maintenance costs: The structure of fiber optic laser cutting machine is relatively simple, and the maintenance requirements are lower than traditional equipment.

High ROI: High efficiency, low operating costs and high flexibility work together to ensure that cnc fiber laser cutting machine brings considerable return on investment.

Environmental advantages

Compared to the smoke and noise generated by plasma cutting or the water stains and waste generated by water jet cutting, laser cutting is cleaner. Combined with an efficient dust removal system, it can create a safer and more environmentally friendly working environment and meet strict production standards.

Upgrade your manufacturing capabilities:

Fiber Laser cutting machines are not only metal processing tools, but also the key to improving the competitiveness of enterprises and realizing intelligent manufacturing. Whether you are pursuing precision parts, efficient mass production, or flexible customization, laser technology can provide reliable and efficient solutions. Contact our technical team to customize your own laser solution!