How to Choose the Right Fiber Laser Cutting Machine?

2025-09-29

Fiber Laser cutting machines are a core component of modern intelligent manufacturing. With their high precision, efficiency, and flexibility, they have revolutionized traditional processing methods. They are becoming increasingly important in both large-scale heavy industry and sophisticated creative industries. With the continuous advancement of technology, the cost of laser cutting machines is decreasing while their cutting capabilities are increasing, promising even broader applications.

What is a laser cutting machine?

A laser cutter machine is a CNC machine that uses a laser (energy source) to generate a high-power laser beam. This beam is transmitted and focused through a series of lenses (reflectors and focusing lenses), resulting in a tiny spot of light with extremely high energy density. This spot rapidly melts, vaporizes, or reaches a ignition point. A high-speed airflow then blows away the molten material, achieving cutting.

Simply put, laser cutting machine's like an extremely precise and sharp "knife" made of light. Controlled by a computer, it can cut any complex pattern into a variety of materials.

What is the main difference between a fiber laser vs a CO₂ laser?

The main types of laser cutting machines are: CO2 laser cutting machines can cut metals and many non-metallic materials, such as acrylic, wood, leather, and cloth. However, they are slow and consume a lot of power, so they are currently mainly used for non-metallic materials. Fiber laser cutting machines are the fastest, most energy-efficient, and easiest to maintain, making them the best choice for cutting metals (such as iron, steel, aluminum, and copper).

How to Choose the Right Fiber Laser Cutting Machine in China?

Buying a fiber laser cutting machine in China can be an excellent decision due to the competitive prices and wide variety, but it requires careful planning to avoid costly mistakes. Don't know how to choose a laser cutting machine? Aorelaser will teach you 4 key steps from power, brand, configuration to after-sales service to help you buy the most suitable and cost-effective equipment and save costs.

Step 1: Define Your Own Requirements (Before you contact suppliers)

This is the most critical step. You need to have a deep understanding of your processing needs, including cutting material type and thickness, cutting quality and accuracy, production volume, budget, etc.

Material Type and Thickness:

Plates: What material (Mild Steel, Stainless Steel, Aluminum, Copper)do you want to cut ? What is the maximum thickness and size (e.g., 6mm mild steel, 1500mm x 3000mm sheets)?

Pipes: What material and diameter? Are they round, square, or rectangular tubes? What is the maximum wall thickness?

Primary Function:

Plate-Only: A standard flatbed laser cutting machine.

Pipe-Only: A dedicated pipe laser cutting machine (rotating chuck type).

Pipe and Plate (Combined): This is key. You have two options:

Double-use metel laser cutting Machine: A single machine that can be configured with different fixtures for plates and pipes. (More versatile, can be a compromise on speed).

Two Separate laesr metal cutting Machines: A flatbed plate laser cutting machine and a separate pipe laser cutter. (Higher productivity and optimization, but higher cost and floor space).

Production Volume and Speed:

Job Shop / Low Volume: A manual or semi-automatic laer metal cutting machine might be cost-effective.

Medium/High Volume: You need a fully automatic CNC fiber laser cutting machine with a loading/unloading system..

Budget:

This will heavily influence the technology you choose. Be realistic about both the initial purchase price and long-term operating costs (power, gas, consumables).

Step 2: Understand the Key Technical Choices

Based on your requirements, you can now focus on the technical specifications.

1. Laser Source: Fiber Laser is the Default Choice

For metal cutting, Fiber Laser cutting machine is the undisputed king today. It's highly efficient, reliable, and has low maintenance compared to CO2 lasers.

Brand: This is a major part of your cost and performance. main incloud: IPG Photonics (USA), Raycus (China), Max (China).

Choosing Power: For cutting both plates and pipes up to 20mm, a 3kW to 6kW laser is a very common and versatile starting point. Higher power (e.g., 6kW) allows you to cut thicker materials faster, but costs more.

2. Machine Configuration: The Biggest Decision for Plates & Pipes

If you only cut sheet metal or tube, you can choose a standard laser cutter. If you need to cut both, but only a small amount of one, a dual-purpose metal laser cutting machine is more suitable.

Option A: Standard Metal Laser Cutting Machine

Advantages: High precision and efficiency for single sheet or tube processing.

Disadvantages: Inability to cut both sheet and tube simultaneously. The total cost of purchasing a plate laser cutting machine and a tube laser cutting machine is higher than that of a multi-purpose laser cutting machine.

Option B: Dedicated Multi-Purpose Machine (Sheet and Tube Laser Cutting)

Working Principle: An all-in-one machine with one cutting head and two systems: one for the flatbed and the other for the tube rotation system. They operate on the same machine frame.

Advantages: Maximizes productivity. You can cut both sheet and tube simultaneously, eliminating the need to waste time switching between modes. Ideal for high-volume production of both.

Disadvantages: Higher initial investment. Takes up more space.

3. Other key configurations

Control System: This is the "brain" of the machine. like CypCut, They are very capable and user-friendly, with good local support.

Servo Motors and Drives: like Yaskawa (Japan)

Guide Rails and Gear Racks: Look for brands like THK or HIWIN for guide rails.

Chiller: A good chiller (like S&A or Teyu) will protect your most expensive component—the laser source.

Step 3: The Supplier Selection Process in China

Identify Manufacturers: Use platforms like Made-in-China.com, Alibaba.com, or industry-specific B2B sites. Focus on companies from key industrial hubs: Wuhan, Jinan, Guangdong, Jiangsu; China's top 6 laser cutting machine suppliers: HGLASER, Han's, Bodor, Senfeng Laser, gweike Laser, Aorelaser,etc.

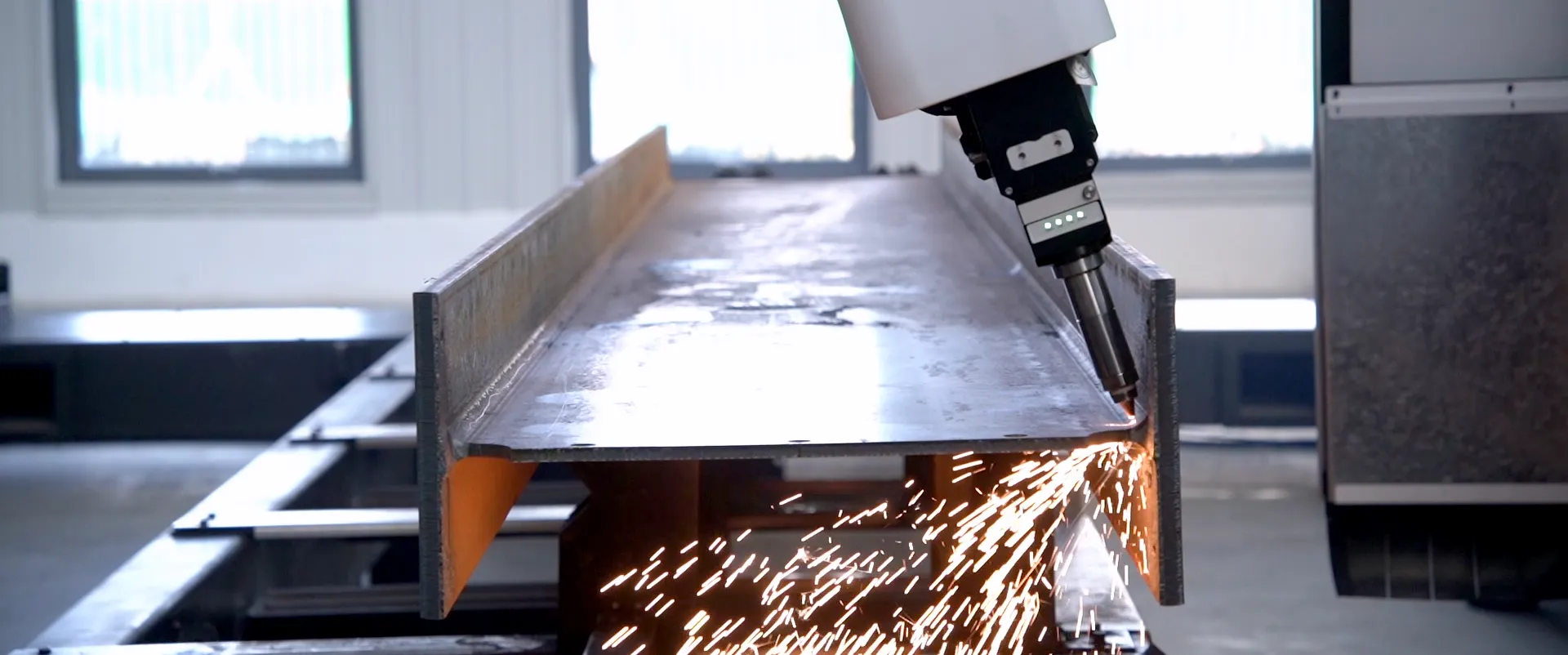

Aore laser All-in-One Laser Cutting Machine

Multi-station machining, the all-round expert in the field of steel processing; power: 12kw-40kw

Wide range of processing: H-beam, I-beam, Channel, Angle, Reducing Beam, Plate, Square Pipe, Round Pipe and so on.

All-purpose cutting: It can perform one-stop processing of opening, beveling, over-welding holes, marking, and truncation for profiles; it can also perform processing of opening, vertical cutting, and beveling cutting for plates; if you also have processing needs for square and round pipes, they only need to configure the corresponding pipe processing device, which can meet the needs for processing of opening, truncation, beveling cutting and through-line cutting for pipes.

Multi-station design: It can realize the “mix and match” processing of different metal materials, for example, when the section steel is cut in the processing area, the pipe which has been processed earlier can be discharged at the same time, and the loading area can be used for loading the plate at the same time. Not only is there no need for frequent stoppages because of a single station, but the synchronized cycle of loading, cutting and unloading can also be realized.

Improve efficiency and increase production : Conventional plasma undercutting requires a flow of 8 processes. Laser doweling requires only 4 processes, which improves the doweling efficiency and increases the processing output.

Reduced labor costs: Compared with the traditional plasma doweling, laser doweling process is reduced, the corresponding staff demand is also reduced, laser cutting machine with its high degree of automation not only enhances the production efficiency, but also simplifies the operation process, thus reducing the number of required labor, reducing the enterprise's labor costs.

Freedom to customize ultra-large format :the bed has been completed with a standardized design, which can be added to the basic standard width by a length of 4 meters and freely customized according to the customer's needs.

Safety is no trivial matter : In order to protect the personal safety of the staff, we have installed surround protection and safety grating in the beam, and at the same time, we have also added a burn board inside the surround, double protection to ensure that the staff are not hurt by the laser and mechanical injuries.

Step 4: After-Sales Service

Is installation and training included? What is the response time for a service engineer?

Aorelaser provide online and offline installation services and training, 24*7 hours online after-sales service.

What is the warranty period for the machine and the laser source?

laser source: 3 year warranty.

Do they have English-speaking engineers?

Our laser metal cutting machines have been sold to many countries around the world, including the United States, Canada, Mexico, Brazil, Bulgaria, South Korea, India, Turkey, Saudi Arabia, etc. After-sales engineer has more than 3 years of work experience and can speak English.

AORE Laser is a global high-tech enterprise specializing in intelligent metal processing solutions. We’re committed to delivering advanced metal processing solutions that enable smart, efficient, and sustainable manufacturing. If you have any questions about the machine, please feel free to contact us.