The Ultimate Guide to CNC Fiber Laser Tube Cutting Machines

2025-09-15

In industrial manufacturing, precision, efficiency, and versatility aren't just advantages; they're necessities. For companies processing metal tubes, fiber laser tube cutting machines offer a radical change in inefficiency and poor cutting accuracy, boosting efficiency by 35%. Aore Laser is at the forefront of this innovation, providing advanced CNC laser tube cutting solutions that empower factories and workshops to boost productivity and creativity.

What is a Tube Laser Cutting Machine?

A fiber laser cutting machine is a high-precision processing device that uses a fiber laser as a light source to cut materials by focusing a high-energy-density laser beam. A tube laser cutting machine, based on fiber laser technology, is specialized for high-precision cutting, hole-making, and complex contour processing of various metal tubes (such as round, square, rectangular, special-shaped tubes, channels, and angles). Leveraging the laser's high energy density, high directivity, and high monochromaticity, tube laser cutting machine achieves efficient and precise tube processing, making it a core piece of equipment in modern tube processing applications, such as steel structures, automotive manufacturing, medical devices, and furniture hardware.

In industrial manufacturing, precision, efficiency, and versatility aren't just advantages; they're necessities. For companies processing metal tubes, fiber laser tube cutting machines offer a radical change in inefficiency and poor cutting accuracy, boosting efficiency by 35%. Aore Laser is at the forefront of this innovation, providing advanced CNC laser tube cutting solutions that empower factories and workshops to boost productivity and creativity.

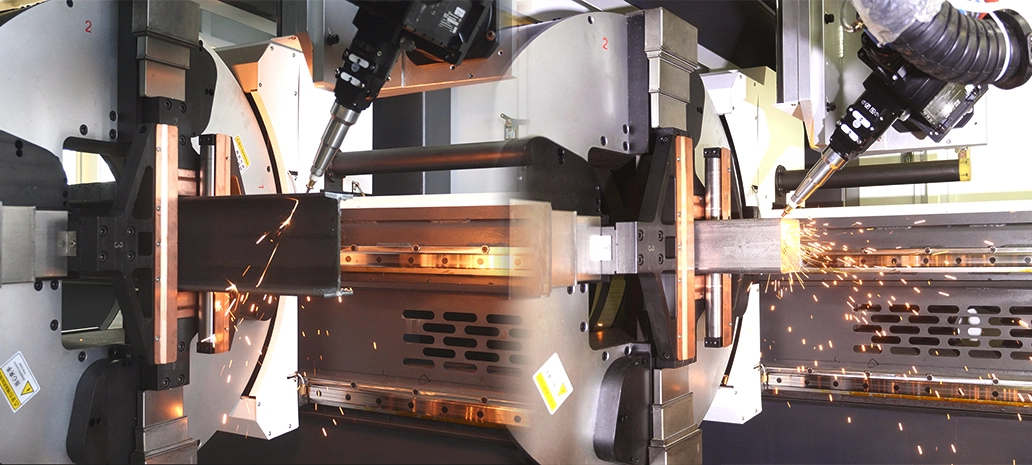

Several key components of tube laser cutting machine:

Fiber Laser Source: The heart of the tube laser cutting machine, generating a powerful and precise laser beam.

Intelligent control system: The brain that translates digital designs (e.g., CAD files) into precise cutting instructions.

Cutting Head: Contains lenses that focus the laser beam onto the material, often equipped with capacitive height sensors to maintain optimal distance.

Material Handling System: A set of chuckers, drives, and supports that securely hold and rotate the tube or pipe during the cutting process, allowing for complex cuts on all sides without repositioning.

This combination makes a laser pipe cutting machine capable of processing a wide range of shapes—including round, square, rectangular, and oval tubes—from various metals.

Advantages of cnc laser tube cutter

High-Precision Cutting: High-precision cutting accuracy, excellent verticality, and burr-free cuts eliminate the need for post-processing, reducing secondary processing costs.

High Processing Efficiency: Compared to traditional sawing and punching processes, cnc laser tube cutter speeds can be increased by 3-5 times.

Flexible Processing: Capable of processing any complex contour without changing molds; simply modifying the CNC program allows for switching between different processing options, making it suitable for small-batch, high-variety orders. Modern CNC tube laser cutting machine interfaces are intuitive and easy to learn, reducing the training time required for operators.

Wide Material Compatibility: Capable of cutting metal pipes such as carbon steel, stainless steel, aluminum alloy, copper alloy, and titanium alloy, with thicknesses ranging from 0.5 to 20 mm (depending on laser power).

Low Consumables and Low Maintenance: cnc laser tube cutter offer a lifespan of up to 100,000 hours (compared to approximately 10,000 hours for conventional CO₂ lasers). Without the frequent replacement of consumable parts like lamps and lenses, maintenance costs are reduced by over 60%. Additionally, low power consumption compared to other industrial cutting methods and reduced labor costs contribute to a lower cost-per-part.

Applications: Where Can a Laser Pipe Cutting Machine Be Used?

The versatility of our laser pipe cutting machine makes them ideal for a vast array of industries:

Steel Structure & Construction: Processing scaffolding tubes, guardrail tubes, and steel structural connectors (e.g., perforated square tubes, beveled round tubes).

Automotive & Rail Transit: Processing automobile exhaust pipes, frame tubes, chassis components, and high-speed rail seat frame tubes (processing complex, irregularly shaped holes).

Medical Devices: Processing surgical instrument tubes (e.g., stainless steel capillary tubing, high-precision, irregularly shaped cuts).

Furniture & Hardware: Processing modern furniture frames, bed frames, table and chair bracket tubes, and fitness equipment tubes (e.g., grooved round tubes, curved cuts).

Power & New Energy: Processing solar panel brackets, cable protection tubing, photovoltaic bracket tubes, and oil and gas pipeline components (batch drilling and long-distance continuous pipe cutting).

Architecture & Construction: Structural frames, handrails, stairs, and decorative elements.

Agriculture & Heavy Machinery: Processing hydraulic cylinders, tractor parts, and equipment frames.

How to Choose the Right CNC Laser Tube Cutter?

When selecting a laser cutting machine for tubes, consider these critical factors:

Laser Power (W): Determines cutting speed and capability. Higher power (e.g., 1000W-12000W+) can cut thicker materials faster.

Tube Capacity (Diameter & Length): The maximum tube diameter and length the machine can accommodate. Ensure it fits your standard workpiece sizes.

Cutting Range (Shape & Thickness): The types of profiles (round, square, etc.) and the maximum wall thickness it can process in various materials (mild steel, stainless steel, aluminum, copper).

Automation Level: Options range from manual loading to fully automated production lines with robotic arms for loading and unloading.

Software Compatibility: Ensure the machine's CNC software integrates smoothly with your existing design and ERP systems.

Why Choose Aore Laser as Your Partner?

At Aore Laser, we don't just sell machines; we provide complete manufacturing solutions. Our tube laser cutting machines offer superior performance, durability, and unparalleled support.

Expert Engineering: 120+ professional engineer with Years of industry experience are built into every machine.

Global Support & Service: Our network of technicians and spare parts ensures minimal downtime, no matter where you are located.

Comprehensive Training: We ensure your team is fully confident in operating and maintaining the new equipment.

Custom Solutions: We can tailor a CNC laser tube cutter system to meet your specific production needs and space requirements.