The Ultimate Maintenance Checklist for Your Laser Pipe Cutting Machine

2025-10-23

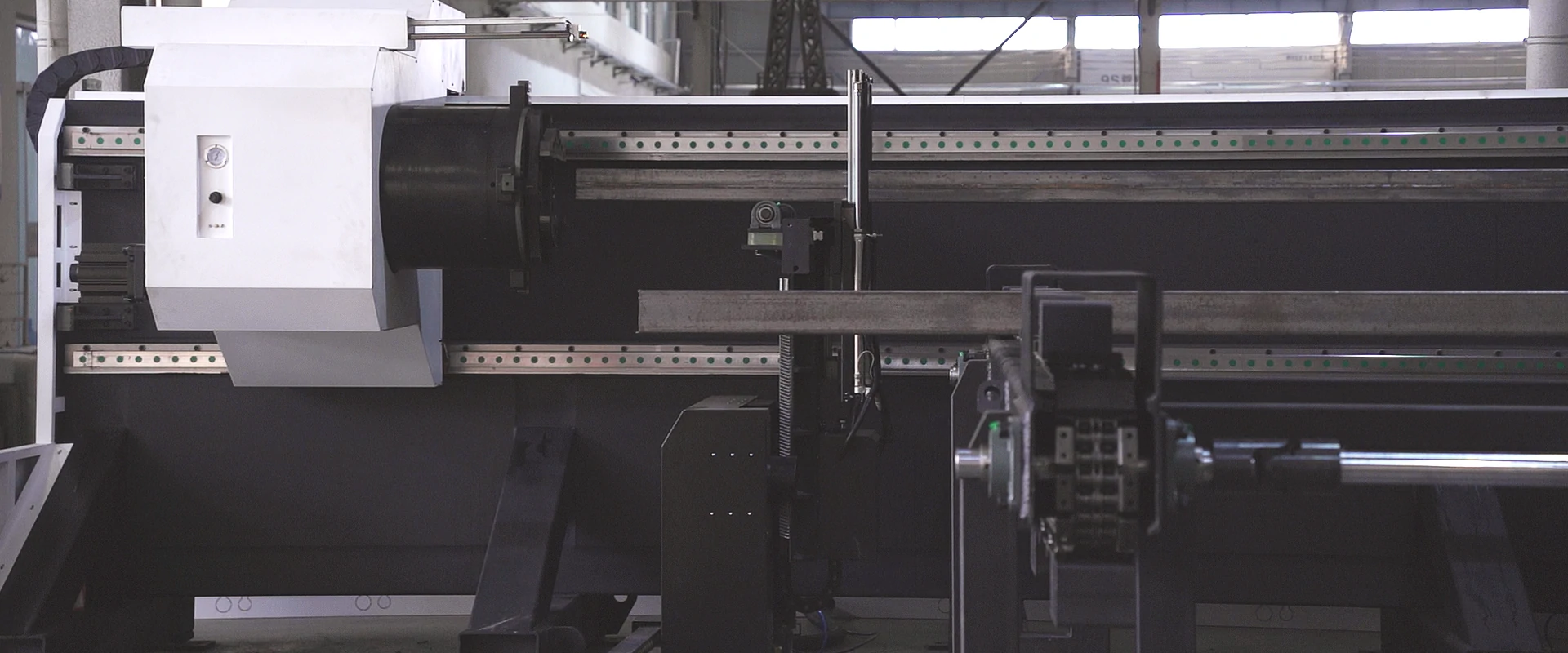

Your laser pipe cutting machine is a significant investment and the workhorse of your fabrication shop. Like any high-precision machinery, its performance and longevity are directly tied to one critical factor: a consistent and proactive maintenance routine.

Neglecting maintenance leads to declining cut quality, unexpected downtime, costly component replacements, and ultimately, a hurt to your bottom line. This comprehensive guide provides a step-by-step maintenance checklist to keep your machine running at peak efficiency.

Why Should We Regular Maintenance CNC Laser Tube Cutter?

Before we dive into the checklist, understand the "why":

Preserve Cut Quality: Contamination on lenses and nozzles directly causes poor edge quality, slag adhesion, and dimensional inaccuracies.

Extend Component Lifespan: Regular cleaning and inspection can double or triple the life of expensive parts like the laser source, focus lens, and nozzles.

Reduce Operational Costs: Preventing a major failure is always cheaper than repairing one. Minimize surprise downtime and keep production on schedule.

Ensure Operator Safety: A well-maintained machine is a safe machine. Proper upkeep prevents issues like gas leaks, electrical faults, and fire hazards.

Precautions when using the laser tube cutting machine:

Installation conditions

(1) Grounding requirements: the equipment installation floor should be level, flatness within ± 5mm, the entire installation surface of the concrete thickness of not less than 200mm.

(2) Space requirements: the distance between the left and back side of the machine tool and the workshop wall should be more than 1200mm; the distance between the laser and the wall should be more than 1000mm.

(3) Environmental requirements: the equipment should be stored in a dry, well-ventilated environment, the ambient temperature between -10 ℃ ~ 40 ℃. It is recommended that users with the conditions to provide constant temperature and humidity for the use of the equipment environment. The ambient temperature of the installation site should not be lower than 4℃ when the equipment is powered off.

Note:Direct sunlight or one side of the wind should be avoided to cause thermal deformation (such as installation can be installed in the window position to install shutters to avoid related situations).

(4) Inside the electrical control cabinet, users are not allowed to connect external wires and sockets, nor are they allowed to connect drills, angle grinders, etc. to the electrical control cabinet; otherwise, AORE Laser will not be responsible for the resulting damage to the components.

(5) It must be ensured that there are no particles or substances around the equipment that can absorb radiation with a wavelength of 1.064 μm, so as not to affect the quality of cutting. For example, solvent-containing vapors released during the painting process, or vapors generated by degreasing equipment.

(6) Checking the water lines

Turn the chiller switch knob, (due to different models of chiller, turn the knob, you may need to click the start button on the panel) at this time the chiller will work ,check the entire water circuit of the interface, if you find leaks, immediately turn off the chiller, and then go to the place of rectification of the leaks. Repair and then test to ensure that there is no water leakage .

(7) Check the air lines

First, make sure that there is corresponding gas in your gas supply device, and then check whether all gas circuits and interfaces are connected. Turn on the switches of each gas supply device, respectively unscrew the switches on the oxygen meter and nitrogen meter. It is recommended that the oxygen meter should be turned to 0.3-1.0Mpa, and the nitrogen meter should be turned to 1.0-2.5Mpa. If you hear the sound of air leakage, find its position and solve the problem of air leakage. After ensuring that there is no air leakage, click "N2", "Air" or "O2" in the operation software to check whether the air is out, and then click "N2", "Air" or "O2" to check whether the air is off. In case of any abnormality, it shall be properly solved.

Daily Maintenance (Before or After Each Shift)

These 10-minute checks can prevent the majority of common issues.

Visual Inspection: Do a quick walk-around. Look for any loose bolts, signs of wear on cables/hoses, or any obvious damage.

Clean the Chuck Jaws & Central Frame: Use a brush and cloth to remove metal dust, debris, and oil from the chucking area. Buildup here can cause misalignment and poor cutting.

Inspect & Clean the Nozzle: The nozzle is critical for gas flow and beam focus. Check for spatter, dents, or ovalization. Clean it carefully with a nozzle cleaning tool or a wooden stick (never metal!).

Check Gas & Air Pressure: Ensure your assist gas (Oxygen, Nitrogen) and compressed air are at the correct pressures as specified for your material and thickness.

Empty the Water Separator: If your machine uses compressed air, drain the water separator to prevent moisture from entering the laser path and optical components.

Weekly Maintenance

Set aside 30-60 minutes each week for these deeper cleaning tasks.

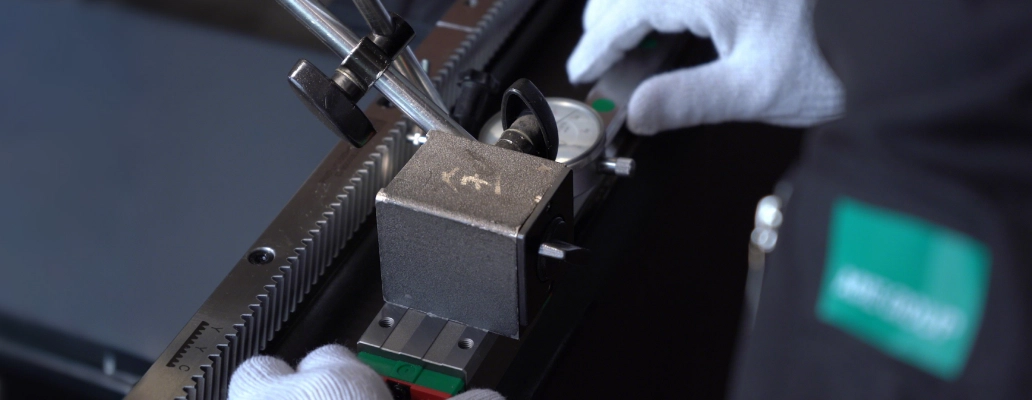

Clean the Optical Lens: This is a delicate but crucial task.

Carefully remove the lens holder. Use a lens cleaning solution and photographic-grade lens tissue or cotton swabs. Gently wipe in a circular motion from the center outward. Inspect for any scratches or coating damage.

Clean the Exhaust System & Filters: Check the pre-filter for large debris. A clogged exhaust reduces fume extraction, harming cut quality and creating a health hazard.

Lubricate the Guide Rails & Ball Screws: Wipe away old grease and dirt first, then apply a thin, even new layer to ensure smooth axis movement.

Inspect the Cooling System: Check the coolant level in the laser chiller. Look for any signs of algae growth or contamination. The chiller's external filter should be cleaned.

Need a Reliable Partner for Your Laser Cutting Needs?

At Aorelaser, we don't just sell high-performance laser tube cutters; we support them. From providing detailed maintenance guides to offering expert technical support and genuine spare parts, we're here to ensure your success.

Contact us today to learn more about our durable and easy-to-maintain laser tube cutting solutions.