CO2 Laser vs. Fiber Laser: What Are Your Options?

2025-08-13

How do I choose a laser cutting machine? How does a metal laser cutter differ from other types of machines? These simple questions can highlight the confusion users face when choosing equipment. They are common questions for purchasing managers and engineers in manufacturing companies, as well as small business owners new to laser processing.

Fiber laser cutting machines are currently the mainstream model on the market, but CO2, plasma, and water jet lasers still have specific applications. Different laser cutting machines vary significantly in cutting capacity, energy consumption, and maintenance.

Laser cutting machines differ primarily in several aspects, and choosing the right machine depends on your specific needs (such as material, thickness, precision, budget, and production volume). The following are the key differences:

What is the difference between a metal laser cutter and a CO2 laser cutter?

Fiber laser cutting machine:

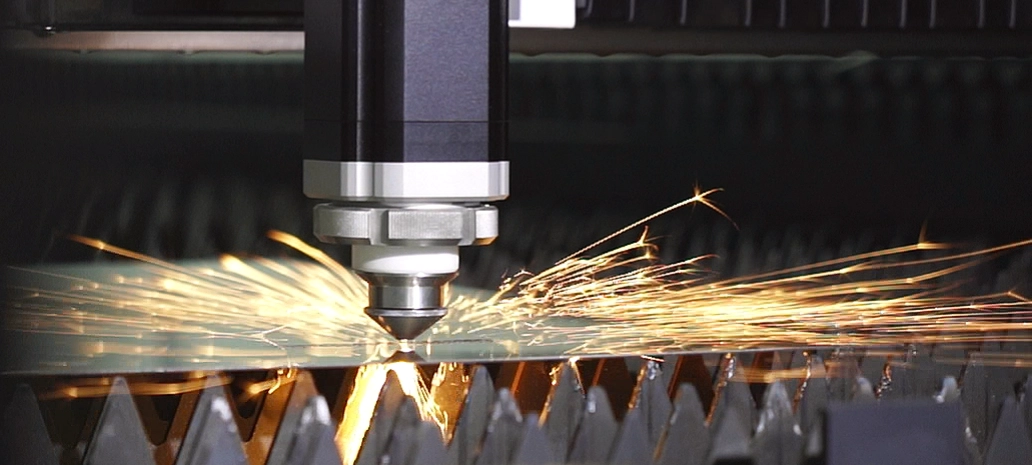

Operating Principle: Laser light is generated by semiconductor diode pumping. The laser light is transmitted to the cutting head via a flexible optical fiber.

Advantages:

High electro-optical conversion efficiency (30-50%): Metal fiber laser cutting machines are extremely energy-efficient and have low operating costs. Good Cutting Quality: Laser cutting machines offer narrow kerfs, minimal heat-affected zones, and smooth cut surfaces (especially for thin plates).

Low Maintenance: Their simple structure eliminates consumable parts like reflective lenses, turbines, or gas laser tubes, making them virtually maintenance-free (primarily due to the protective lens on the cutting head).

High Cutting Speed: Metal laser cutting machines significantly outperform CO2 cutting machines, especially when cutting thin and medium-sized plates (<15mm).

Good Beam Quality: Their small focused spot and high energy density make them suitable for fine cutting.

Stable Operation: Lasers are insensitive to ambient temperature and vibration.

Disadvantages:

Initial Investment: Previously high, but with the maturity of the technology, prices have dropped significantly in recent years, reaching prices comparable to or even lower than CO2 in the low- to medium-power range (<6kW).

Applicable Materials: They can cut highly reflective materials such as copper, brass, and aluminum (thanks to their wavelength characteristics). They offer excellent cutting results on metals such as carbon steel, stainless steel, and alloy steel. However, they are not suitable for cutting non-metals (such as wood, acrylic, and fabric).

CO2 Laser Cutting Machine:

Operating Principle: In a resonant cavity filled with a mixture of CO2, N2, and He gases, high-voltage discharge excites gas molecules to generate laser light. The laser light is transmitted to the cutting head via a system of mirrors.

Advantages:

Good Cross-Section Quality When Cutting Thick Plates: When cutting thick carbon steel plates (>15-20mm), the cut surface is typically smoother and more perpendicular (this has traditionally been its advantage, but high-power fiber laser cutting machines can now achieve this).

Ability to Cut Non-Metals: Its wavelength (10.6μm) is effectively absorbed by non-metallic materials, allowing it to cut wood, acrylic, plastic, leather, cloth, ceramics, and more.

Disadvantages:

Low electro-optical conversion efficiency (10-15%): High power consumption and high operating costs.

Slow Cutting Speed: Especially when cutting thin metal plates, the speed is much lower than that of a fiber laser cutting machine. High and Complex Maintenance: Gases, reflective lenses, turbine bearings, and other consumable parts require regular replacement, and the optical system requires precise calibration, making maintenance labor intensive and highly specialized.

Noisy Operation: High-speed turbines generate considerable noise.

Difficulty Cutting Highly Reflective Metals: Cutting highly reflective materials such as copper and brass is extremely difficult and may even damage the equipment.

How to Choose a laser cutting machine?

Identify the Main Processing Materials: Is it primarily metal? What metals? Are there any non-metals? Are there a high proportion of highly reflective metals (copper, aluminum)?

Determine the Material Thickness Range: What is the most commonly cut thickness? What is the maximum thickness requirement?

Evaluate Production Volume and Budget: What is the production volume? What is the initial investment budget? Do you prioritize equipment price or long-term operating costs?

Precision Requirements: What are the requirements for part dimensional accuracy and cut quality?

Sheet Size: What is the maximum sheet size commonly used?

Other Considerations: Factory conditions (power and gas supply), whether automated loading and unloading is required, etc.

AORE Laser cutting machine PU: Your Best Choice

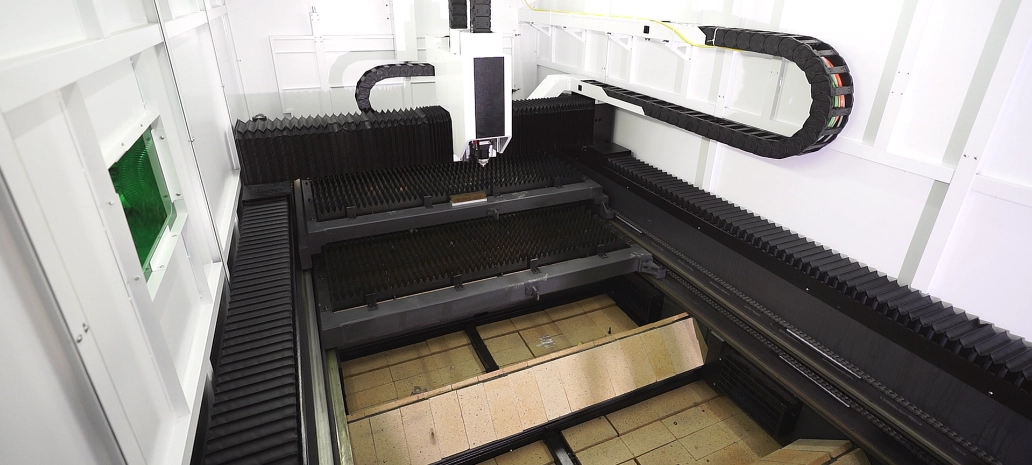

PU-3015 Fully Enclosed High-Speed Laser Cutting Machine, Accelerated Efficiency. Smarter Production. Reliable Performance.

Achieves up to 50%–80% Higher Efficiency: Cutting speed increased significantly, maximizing output and throughput

Low-Gravity Design for Stable Cutting

Ensures smooth operation under heavy load with exceptional structural stability

Lightweight Beam, Speed Optimized

Reduces motion inertia and boosts dynamic response for faster, more efficient performance

Follow-Up Zoned Dust Removal

≥95% dust removal efficiency keeps your workspace cleaner and machine healthier

Intelligent Safety Light Curtain (Optional)

Real-time protective sensing with no blind spots for full operator safety

Smart Line Integration (Optional)

Seamless connection to AORE's loading/unloading system for full-process automation

Application Industry:

Sheet Metal Fabrication、Metal Furniture Production、Electrical Cabinets & Enclosures、Construction Machinery Parts