How to Select Fiber Laser Cutter Power? - Buyer's Guide

2025-12-29

When selecting a sheet metal laser cutting machine, laser power is almost always the first concern for most sheet metal processing shops.

Many people believe that higher power is always better. However, in actual production, whether the power setting is appropriate depends on the material type, sheet thickness, and daily processing methods. Choosing an unreasonable power setting may increase costs without delivering significant benefits.

This article provides a practical overview of how different power levels apply to sheet metal cutting, serving as a reference for sheet metal processing users.

1.What effect does laser power have on the cutting process?

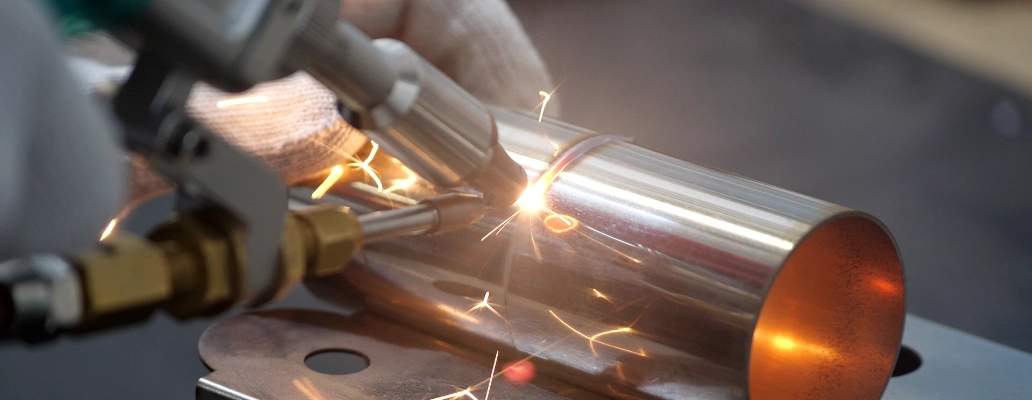

The principle of laser cutting is to use a high-energy-density focused laser beam to expose materials, causing local rapid melting, vaporization, or ablation. Meanwhile, a high-speed auxiliary gas coaxial with the beam blows away the molten material, thereby forming a cut in the material to complete the cutting process.

The power of a sheet metal laser cutting machine not only determines whether cutting is possible but also impacts cutting speed, edge quality, processing stability, energy consumption, costs, and long-term equipment efficiency.

Too low power may result in incomplete cuts or slow speeds.

Too high power often does not significantly improve efficiency when processing thin sheets.

In conclusion, higher laser power sheet mtel laser cutting machine can improve cutting efficiency and allow for processing thicker materials, but it is not a universal solution.

2. Is higher power always better?

Not always. In most sheet metal workshops, daily production mainly involves thin to medium-thin sheets. In these cases, cutting speed is often no longer limited by laser power. Instead, overall efficiency is usually affected by material loading, unloading, sorting, and part handling.

Because of this, ultra-high-power fiber laser cutters do not necessarily increase total output. The machine may finish cutting faster, but the production line as a whole does not move faster.

In addition, high-power laser equipment typically comes with:

Higher initial investment

Increased electricity consumption

More demanding cooling and maintenance requirements

For many fabrication shops, a laser power level that matches real production needs is more practical and cost-effective. In daily operation, a well-balanced metal laser cutting machine often delivers better long-term performance than simply choosing the highest power available.

3. Laser Power vs. Cutting Thickness

1.5-3kW fiber laser cutter: Suitable for cutting thin materials like stainless steel, aluminum, and carbon steel from 1mm to 5mm thick.

6-12kW lasers: Suitable for cutting medium-thickness metals from 5mm to 15mm thick, such as thicker alloy plates or steel plates.

Lasers above 12kW: Suitable for cutting thick plates of titanium, stainless steel, or low-carbon steel exceeding 15mm thickness.

This range is more suitable for daily continuous production, offering a balanced trade-off between cutting quality and efficiency.

4. Laser Power vs. Cutting Material

The physical and chemical properties of different materials vary significantly, directly affecting the ease of laser cutting. Therefore, cutting different metal plates of the same thickness presents different levels of difficulty and requires varying amounts of power.

Carbon Steel

Characteristics: Carbon steel is one of the most common and easiest materials to laser cut, featuring good thermal conductivity and a low melting point.

Cutting Difficulty: Relatively low, but heat input must be carefully controlled to prevent deformation from overheating.

Recommendation: Use a medium-power laser, adjust cutting speed and gas flow to ensure quality cuts.

Stainless Steel

Characteristics: Stainless steel offers high corrosion resistance and hardness, with high reflectivity. Typically demands high edge consistency.

Cutting Difficulty: Medium to high. Requires higher laser power and precise parameter settings. Cutting speed is slower than carbon steel.

Recommendation: Employ a high-power laser, typically using nitrogen or oxygen as the assist gas.

Aluminum Alloy

Characteristics: Lightweight and corrosion-resistant, but exhibits excellent thermal conductivity.

Cutting Difficulty: High, prone to porosity and cracking.

Recommendation: Use a high-power laser with argon gas shielding to minimize the heat-affected zone.

5. How to Choose the Right Sheet Metal Laser Cutting Machine for Your Needs

To choose a suitable fiber laser cutter, you must first clarify your processing requirements.

What metal can a laser cutting machine cut?

First, determine if carbon steel is the primary material. What is the proportion of stainless steel? Is an aluminum sheet a commonly processed material? After all, stainless steel, carbon steel, aluminum, and copper all respond differently to laser power.

How thick can a laser cutter cut metal?

With the same power, different materials can be cut to different thicknesses. Review your order history to determine the most frequently processed sheet thickness range and the proportion of orders exceeding 10 mm in thickness.

Material Processing Area:

The size of the material area relates to the machine bed width. Common processing areas include 3000mm*1500mm and 6000mm*2000mm.

Production Intensity:

If the equipment is to operate continuously for extended periods, stability and consistency are paramount. Appropriate power helps reduce long-term operational risks.

It is generally recommended that the power of a CNC laser cutting machine meet 90% of daily processing needs.

Conclusion:

Laser power is important, but selection should never be divorced from actual processing requirements. Before purchasing a cnc laser cutter for metal, we recommend clearly defining your specific needs to truly enhance efficiency and long-term value. If you have any questions about fiber cutting laser machine applications in the sheet metal processing industry, or require more information regarding model selection, technical support, or services, please feel free to contact us. Explore advanced laser cutting solutions today and inject new vitality into your factory.