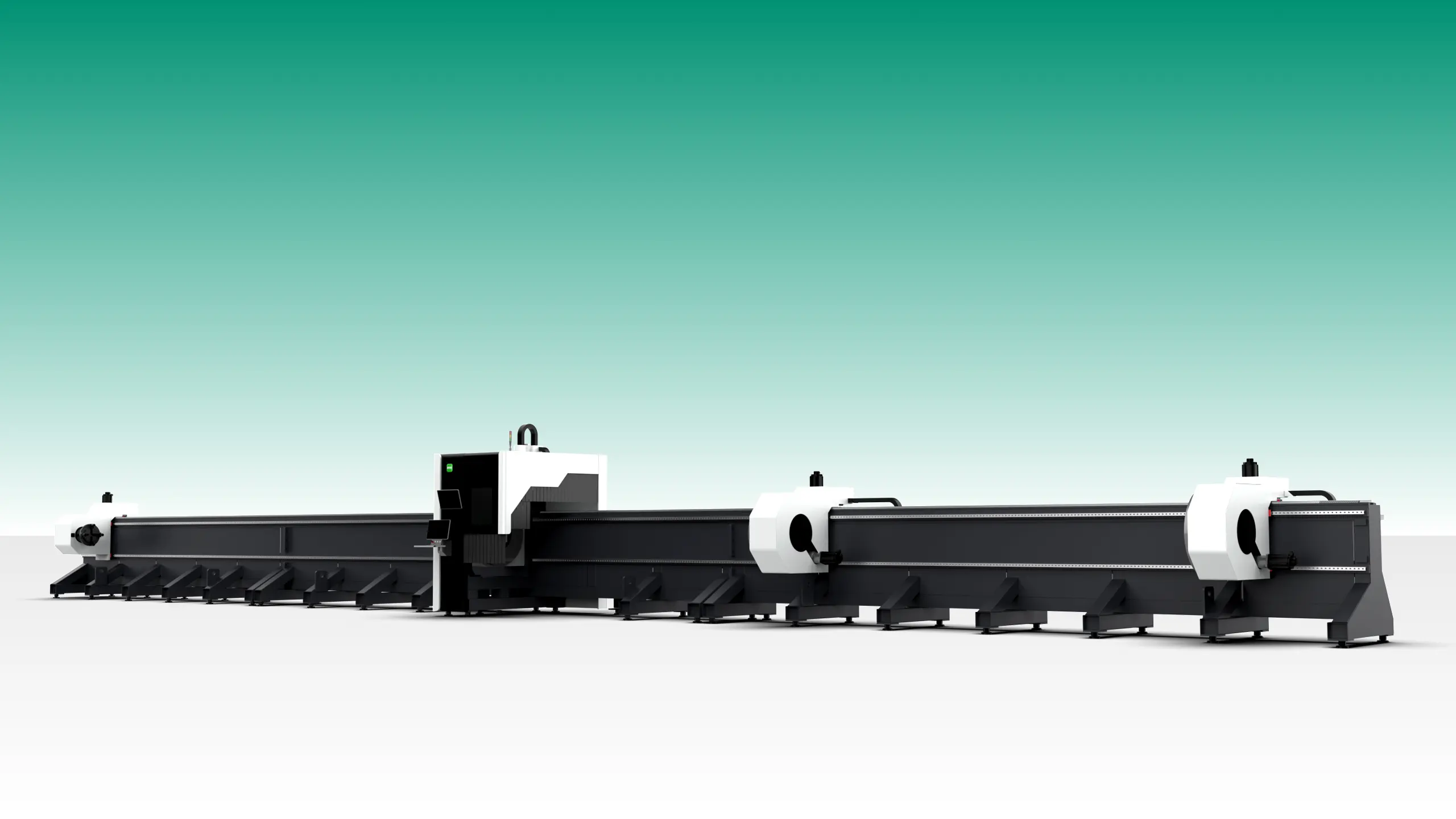

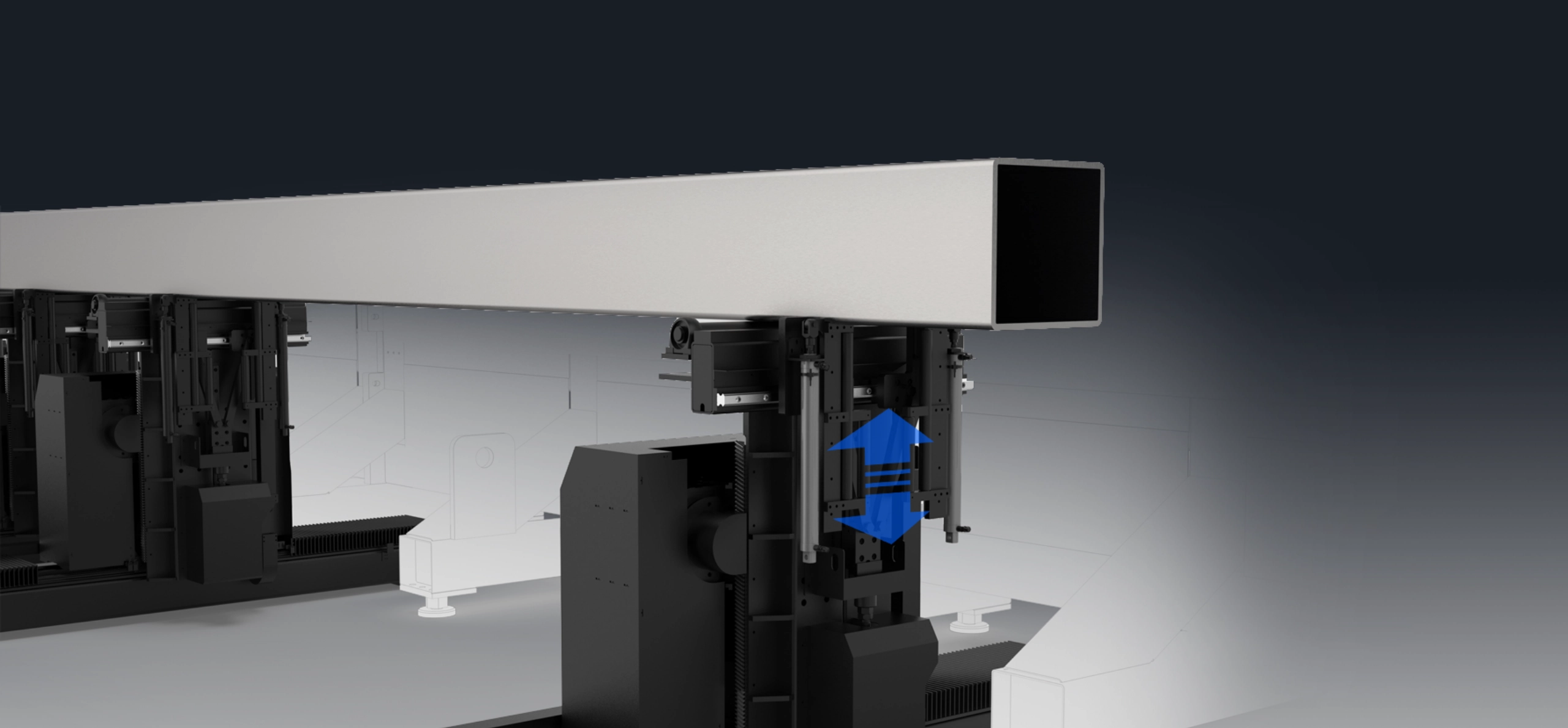

Automatic Loading and Unloading Device

Synchronic loading and unloading for better productivity

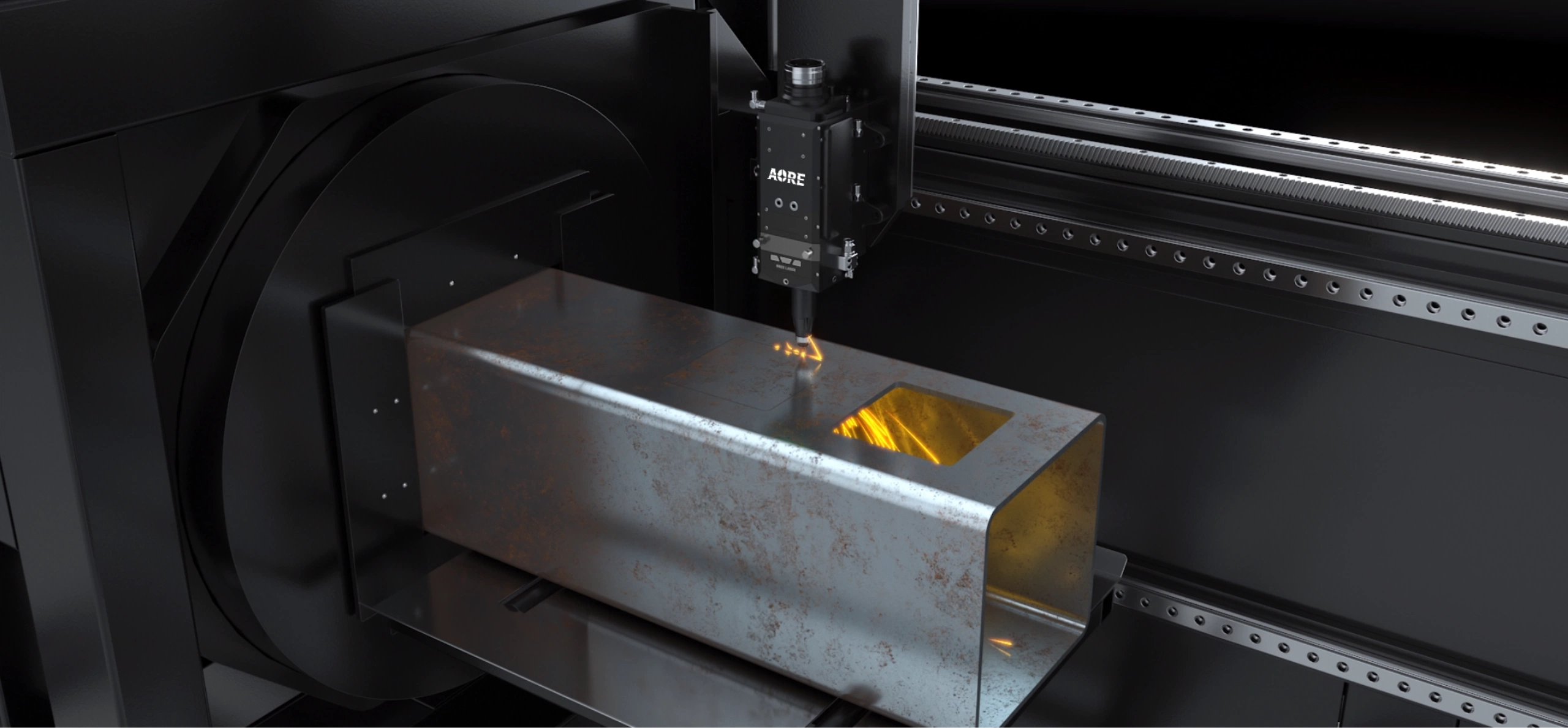

Engineered for Heavy-Duty Tube Cutting

Equipped with a high-strength four-chuck system, the TZ Series delivers exceptional load capacity, firm clamping, and wide material compatibility—ideal for processing large-diameter, thick-walled tubes with ease.

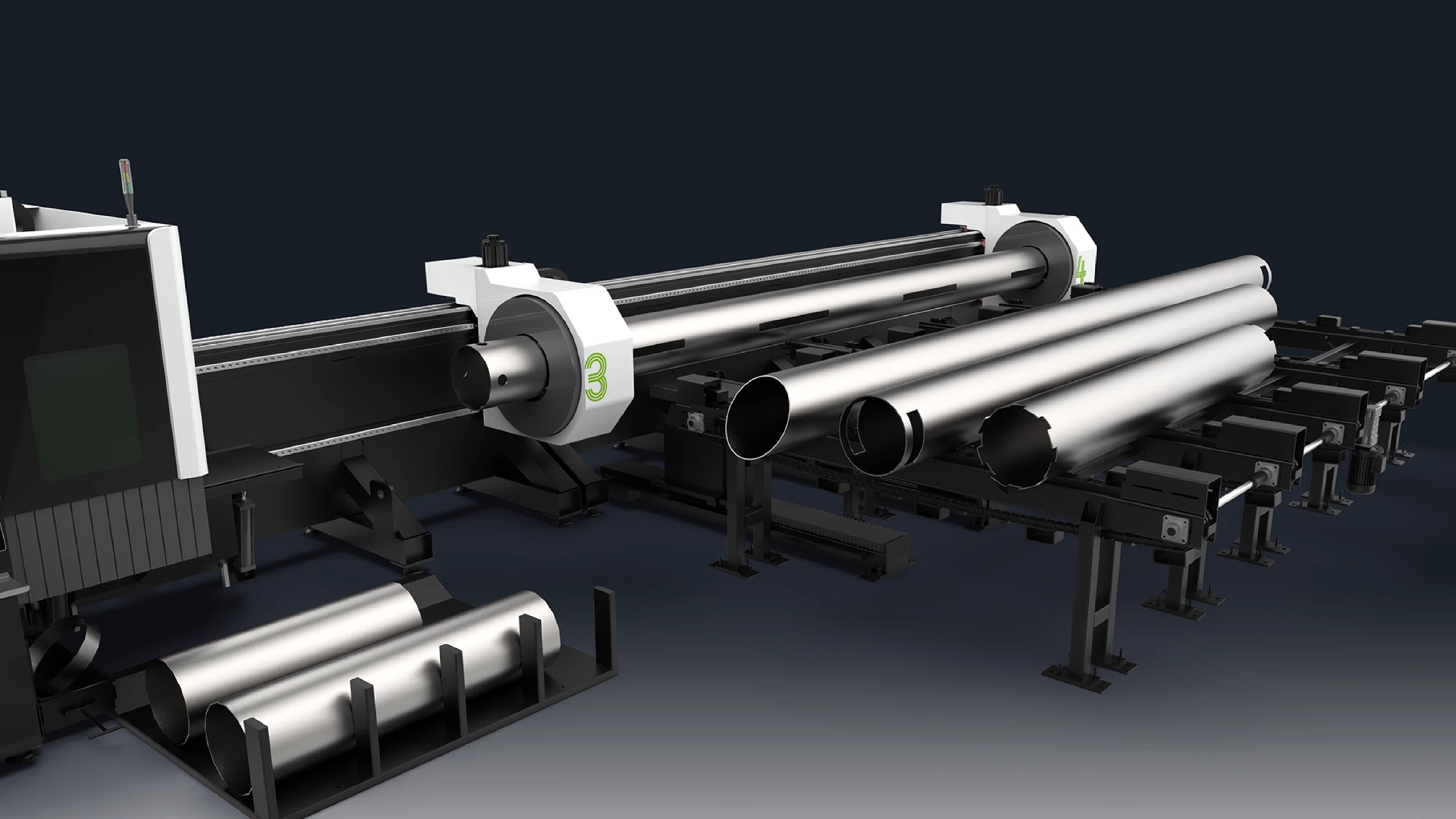

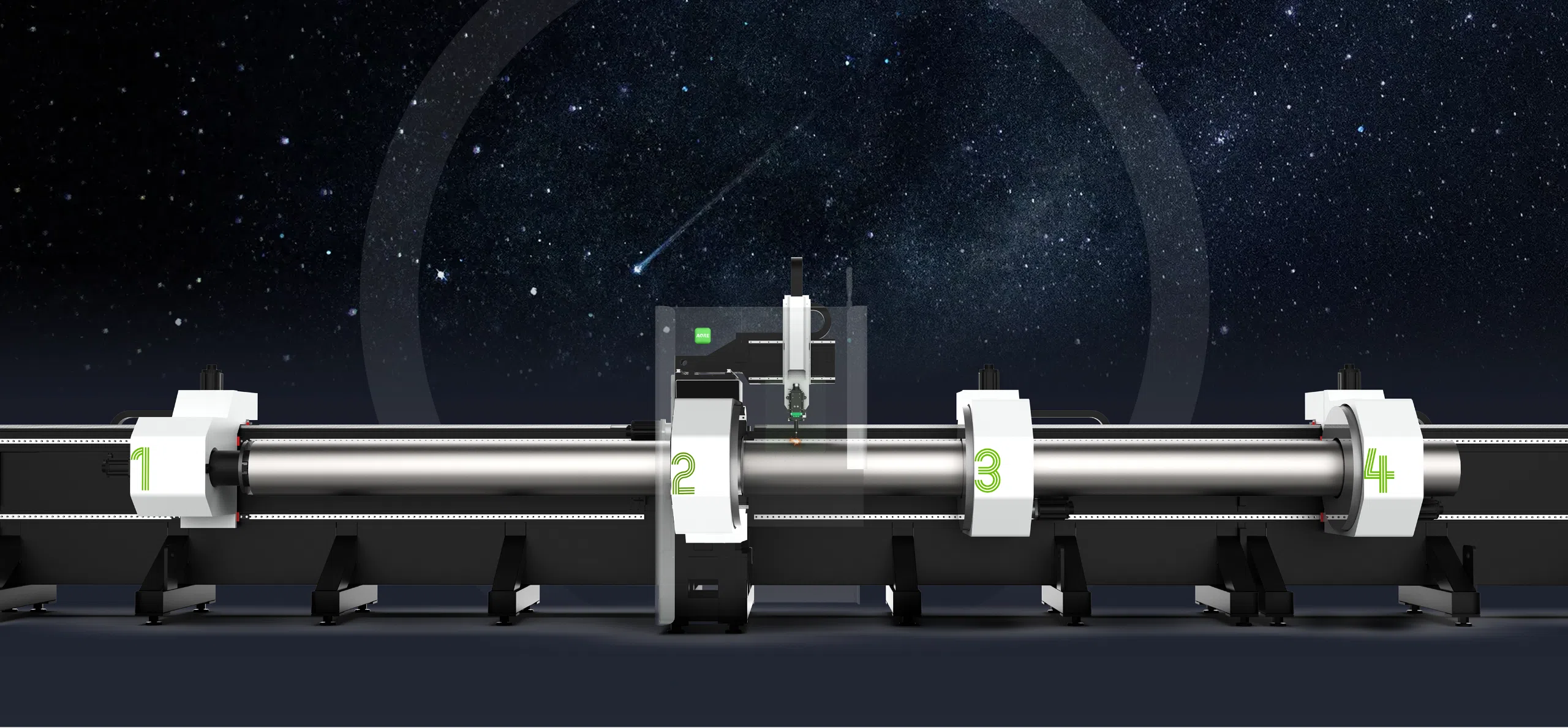

Synchronized Loading and Unloading for Non-Stop Production

The “2+2” four-chuck cutting mode allows simultaneous loading and unloading, keeping the production flow uninterrupted and boosting operational efficiency.

Full-Length Support for Accurate Cutting

The intelligent follow-up support system adjusts lifting height in real-time to prevent tube vibration and sagging, ensuring stable cutting and improved precision and product quality.

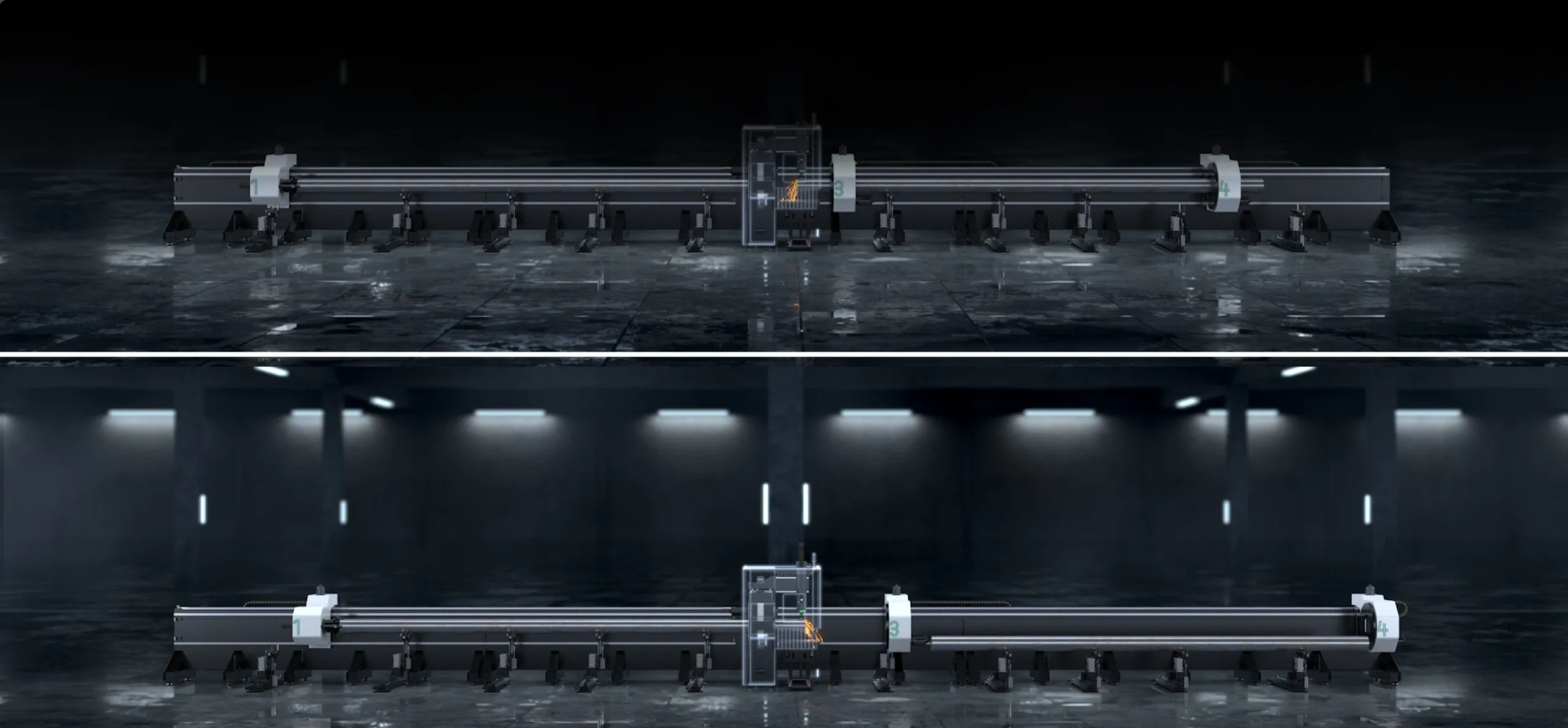

High-Efficiency Static Cutting

Heavy tubes remain stationary during processing, while the laser head moves at high speed to complete cutting—enhancing both cutting stability and accuracy.

Applications

Steel Structure

Construction Machinery

Shipbuilding

Bridge Construction

Heavy-duty Vehicle Manufacturing

Technical Parameters

| Model | TZ12055 | TZ12070 |

|---|---|---|

| Power | 6-20kW | 6-20kW |

| Max. Raw Material Length | Φ40-Φ550mm □40*40-□550*550mm | Φ50-Φ730mm □50*50-□520*520mm |

| Round Tube Diameter | 3000kg | 3300kg |

| Square Tube Side Length | 12000mm | 12000mm |

| Max. Acceleration | 0.3G | 0.3G |