Metal Fiber Laser Cutter Maintenance Manual

2025-05-30

Professional maintenance to maintain the normal operation of the premise of the equipment, Industry data: Regular maintenance can reduce unexpected downtime by 40% and extend equipment life by 3-5 years!

Before putting into operation:

Before the metal laser cutting machine tool equipment is put into operation, the steel laser cutting machine tool must be carefully lubricated according to the lubrication diagram. For ocean transportation and other export products in the equipment

into operation before the first must be cleaned before the factory brush coated with antirust oil, and at the same time must check the entire steel laser cutting machine tool lubrication; if necessary, must be thoroughly removed from all lubrication points and piping in the solidified lubricant.

Note on cleaning operation:

Clean the whole set of equipment regularly; sweep off large dirt or vacuum it off with an industrial vacuum cleaner.

Fiber Laser Cutter Daily maintenance list

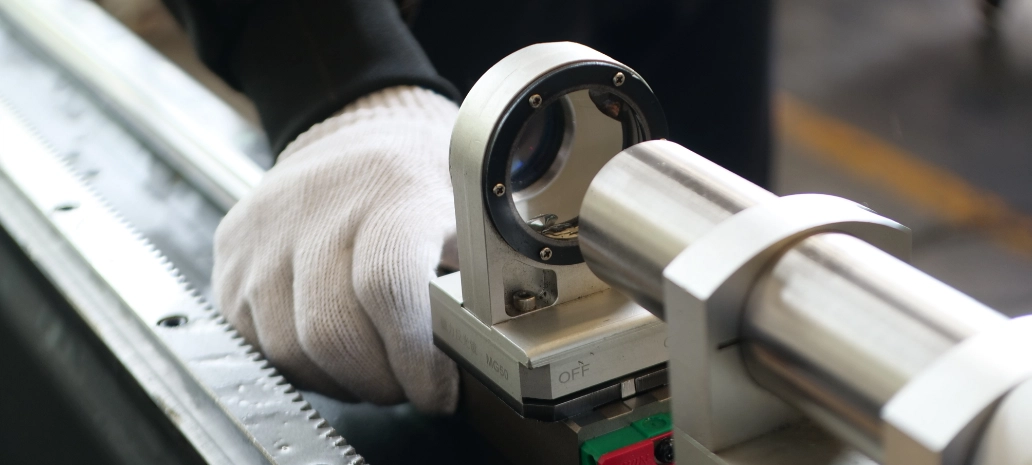

1. Lens cleaning

Frequency: every 8 hours (increased to 2 times in high production)

Steps:

① with anhydrous ethanol + dust-free cotton swabs one-way wipe Metal Fiber Laser Cutter lenses (prohibit back and forth friction)

② check the Metal Fiber Laser Cutter lens coating whether there are scratches (scratches are immediately replaced to avoid damage to the equipment by laser refraction)

2. gas and cooling system monitoring

gas line check:

to confirm that the air pressure is stable

regularly empty the air compressor tank water (to prevent water vapor into the cutting head)

Cooling water maintenance:

Water temperature to maintain 22 ± 2 ℃

Monthly testing of water conductivity

3. Guide and transmission system maintenance

Rack and pinion: Apply white grease after removing metal dust weekly

Steel Laser Cutting Machine Parts

This section focuses on the maintenance of the mechanical components involved in the care and maintenance points. Regular mechanical maintenance in accordance with this manual can significantly increase the service life of the Metal Fiber Laser Cutter 's wear parts and reduce the cost of use.

1. Maintenance of metal laser cutter accuracy

X, Y axis verticality verification and X, Y axis rack and pinion meshing clearance verification

Interval: 1 time/5000h

Tools/materials: Percentage meter, micrometer, square ruler, internal and external hexagonal wrench, cleaning cloth, backlash tooling

Work content: take off the X-dustproof cloth and crossbeam, remove the X-axis protection board and crossbeam left and right guards for X, Y-axis vertical inspection, X, Y two-way meter tolerance ≤ 0.03mm/500mm, to ensure that the X, Y-axis mutually perpendicular to ≤ 0.03mm/500mm, X, Y-axis rack and pinion backlash calibration of ≤ 0.02mm.

Safety precautions: Pay attention to safety during operation.

2. Cleaning chiller filters

Interval: 1 time/quarter

Tools/materials: water hose, cleaning tools, cleaning cloths

Work content: hand press the Metal Fiber Laser Cutter chiller screen “claw”, remove the screen,

use water to rinse and clean the steel laser cutting machine screen to clean.

About Aore Laser After-sales service

After sales service refers to the repair and maintenance services provided to solve equipment or facilities. Aore Laser provides 7 * 24 hours of exclusive one-on-one customer service, which is non-stop all day, quick response 0.5H, quick response to emergency problems, to ensure the first time to solve problems.

In addition, Aore Laser also provides "After-sales Service Manual", which is believed to solve any of your after-sales concerns.