Buyer’s Guide: How to Choose the Best Tube Laser Cutting Machine

2025-05-16

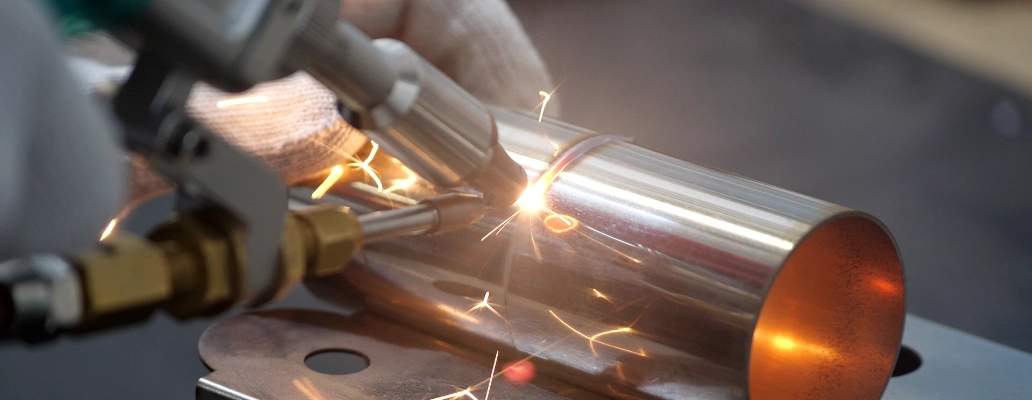

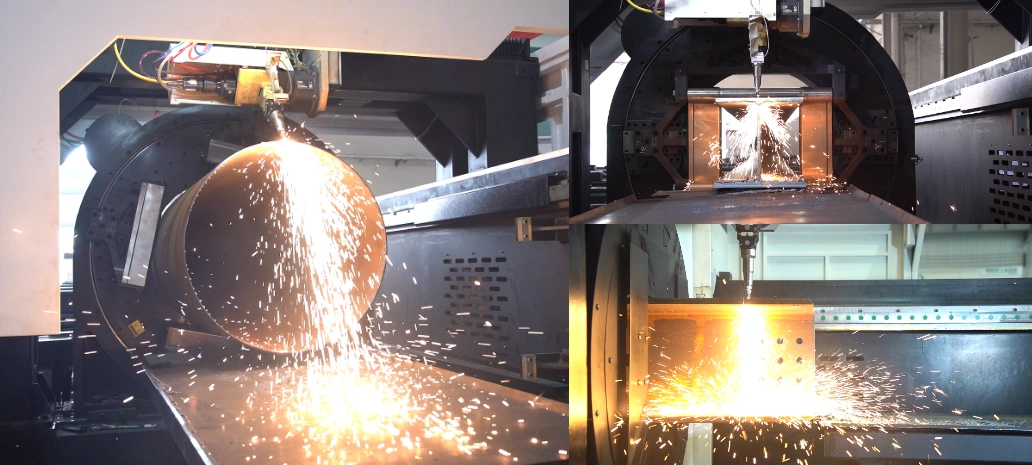

In the fast-evolving metal fabrication industry, fiber laser tube cutting machines have become indispensable for businesses aiming to boost productivity, precision, and profitability. Whether you’re cutting round pipes, square tubes, or complex profiles, choosing the right machine can make or break your ROI.

This guide will walk you through the critical factors to consider when purchasing a fiber laser tube cutting machine, tailored for manufacturers, workshop owners, and procurement managers worldwide.

1. Understand Your Production Needs

Before investing, define your core requirements to avoid overspending or underperformance:

Material Compatibility

What metals do you work with? (e.g., stainless steel, carbon steel, aluminum, copper)

Tube dimensions: Max/min diameter (e.g., 10mm–300mm) and wall thickness (e.g., 0.5–25mm).

Production Volume

High-volume factories need high-power lasers (6kW+) and automated loading/unloading systems.

Small workshops may prioritize 3kW–4kW tube laser cutting machines with manual handling.

Cutting Complexity

Basic 2D cuts vs. 3D profiling for bent tubes or intricate designs.

2. Key Technical Specifications to Evaluate

A. Laser Power & Type

Fiber Lasers dominate the market due to: Higher efficiency vs. CO₂ lasers. Faster cutting speeds .

Power Recommendations:

1–2kW pipe laser cutting machine: Thin-walled tubes (<5mm) for decorative or HVAC applications.

3–6kW laser pipecutting machine: Balanced for medium thickness (up to 15mm) and speed.

8kW+ laser tube cutting machine: Heavy-duty industrial use (20mm+ steel).

B. Precision & Stability

Positioning Accuracy: Look for ±0.05mm or better.

Motion System: Servo motors + gear racks outperform stepper motors.

Chuck Design: Auto-centering chucks reduce setup time for varying tube sizes.

C. Software & Automation

Cutting Software: Ensure compatibility with CAD/CAM files (DXF, STEP) and features like nesting optimization.

Smart Sensors: Collision detection and adaptive feed rate control minimize errors.

Automation Options: Robotic arms or conveyor systems for 24/7 production.

3.FAQs

Q1: What safety certifications should a fiber laser tube cutter have?

Look for CE, or ISO compliance to meet global standards.

Q2: How to reduce operating costs?

Opt for energy-efficient fiber lasers and schedule regular maintenance.

Q3: Can one machine handle both tubes and flat sheets?

Yes! you can choose double-use laser cutting machine

Q4: What’s the typical ROI period?

1–3 years, depending on workload and machine utilization.

4. Pro Tips for Buyers

Request Demos: Test the machine with your own materials.

Check Local Support: Ensure the supplier has technicians in your region.

Future-Proofing: Choose upgradable lasers

Conclusion

Investing in a fiber laser tube cutting machine is a strategic move to stay competitive in metal fabrication. By aligning technical specs with your production goals, evaluating total costs, and partnering with reliable brands, you’ll secure a machine that delivers precision, speed, and long-term value.

Ready to upgrade your workshop? Contact us for a personalized quote!