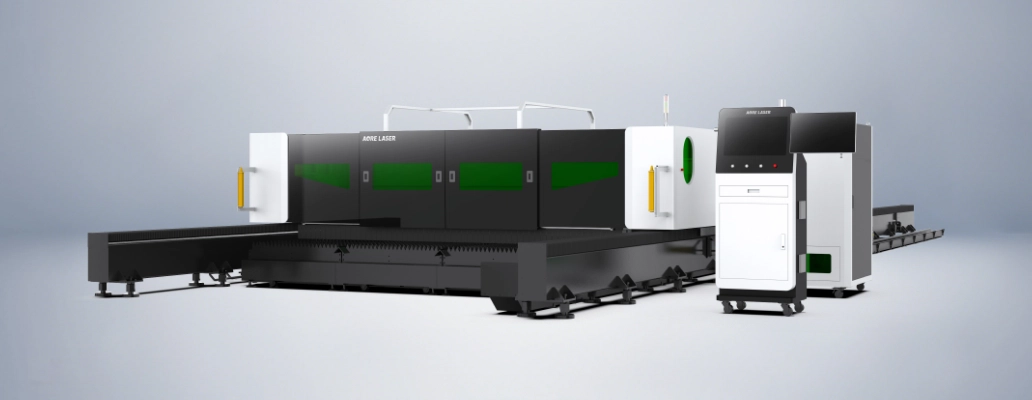

Laser Cutting Machine Repair Guide: Lenses, Water Flow Flying Cut Solutions

2025-08-08

Fiber Laser Cutting Machine Troubleshooting Guide

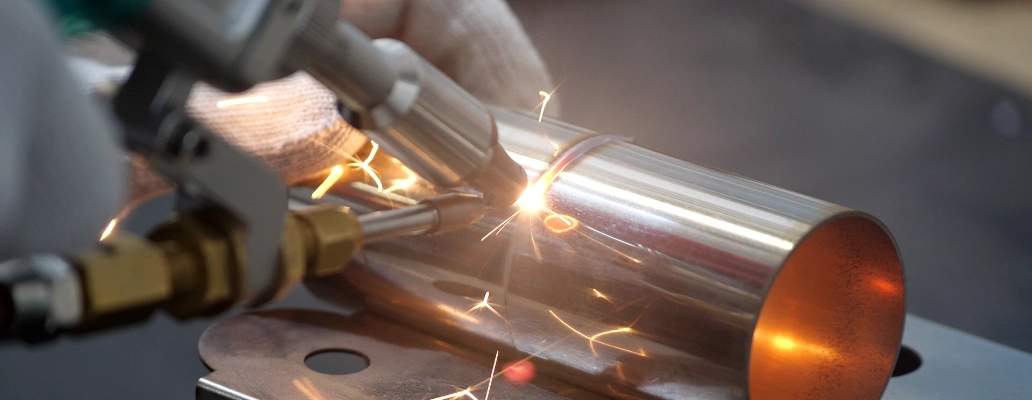

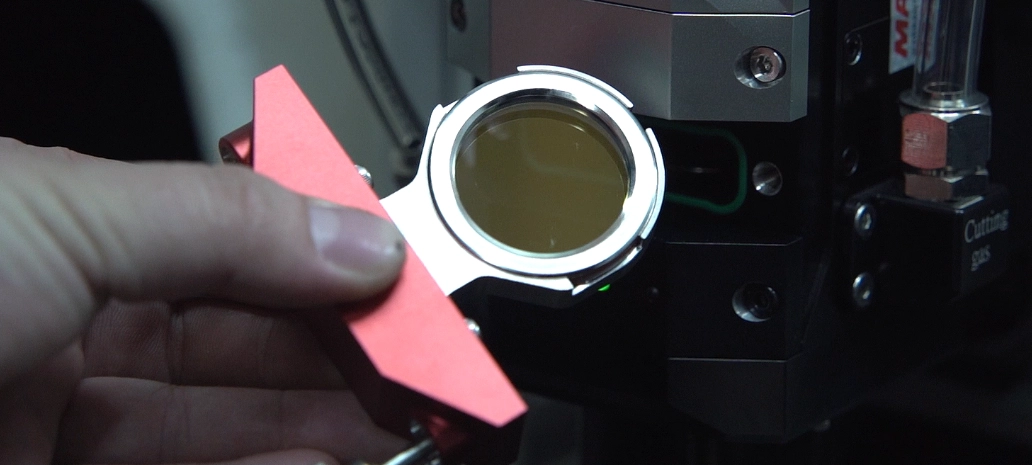

Problem 1: Frequent Protective Lens Burnout

Causes:

Contaminants on lens surface absorbing laser energy

Insufficient or misaligned assist gas flow

Cutting unsuitable materials with wrong parameters

Damaged or poor-quality lens holder

Incorrect focus position or power density

Diagnostic Steps:

For black spots: Check piercing parameters and focal position

Verify start delay in global parameters is set to 0

For white spots: Check air compressor maintenance and tank drainage

Inspect lens optical quality

Solutions:

Adjust start delay to at least 200ms

Drain air tank daily (2-3 times in hot weather)

Replace with original manufacturer lenses

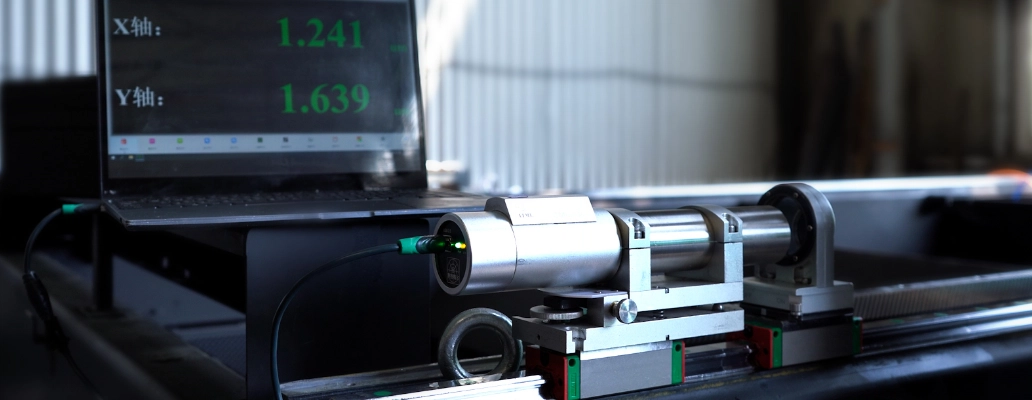

Problem 2: Flying Cut Interruptions

Causes:

Encoder direction error

Faulty encoder cable or feedback signal

Damaged control card

Solutions:

Reset encoder values by sending 10,000 pulses to X/Y axes

If display shows -10,000: Reverse encoder direction in platform config

If display shows 0: Check 15-core cable, then 62-pin connector, then control card

Problem 3: New Machine Water Flow Alarm

Causes:

Airlocks in cooling system

Partially closed water valves

Kinked coolant hoses

Low chiller coolant level

Solutions:

Bleed air from system by disconnecting hoses at laser head

Run pump until bubble-free flow is achieved

Check all valves are fully open

Inspect all hoses for kinks

Top up coolant to proper level

Maintenance Recommendations:

Daily: Drain air tank, inspect lenses

Monthly: Check chiller coolant level and temperature

Quarterly: Perform encoder calibration

For persistent issues, contact technical support with:

Machine model and serial number

Detailed description of problem

Any error codes displayed