The Ultimate Guide to Laser Cleaning Machines: How They Work, Benefits

2025-08-15

Tired of the mess, waste, and limitations of traditional industrial cleaning? Looking for a cleaner, smarter, and more powerful solution? Laser cleaning machines, as a revolutionary "light cleaning" technology, are rapidly becoming the preferred solution for leading companies worldwide. Demand for efficient, non-destructive, and environmentally friendly surface cleaning is growing in industrial manufacturing, cultural heritage preservation, precision machining, and other fields. Traditional methods like sandblasting and chemical cleaning are not only inefficient and can damage substrates, but also pose environmental pollution and health risks.

What is a Laser Cleaning Machine?

A fiber laser cleaning machine is an advanced cleaning device that uses a high-energy-density, short-pulse laser beam to target surfaces. Laser cleaning technology is revolutionizing surface treatment and repair in countless industries. By harnessing the focused energy of light, it offers unparalleled precision, efficiency, and environmental performance.

Energy Focusing: A laser generates a high-intensity pulsed laser beam.

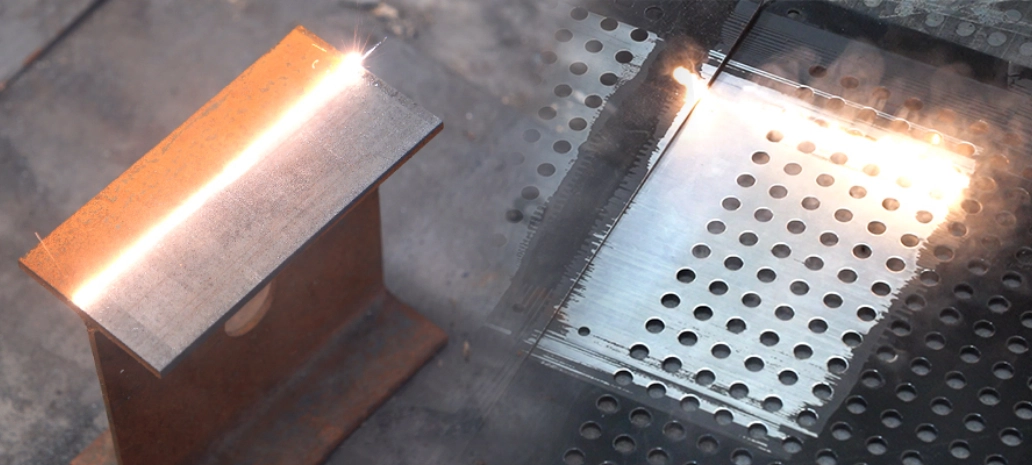

Precise Irradiation: The beam is transmitted via a galvanometer system or optical fiber, precisely focusing it onto the surface to be cleaned (such as rust, paint, oil, oxide layers, coatings, etc.).

Energy Absorption Difference: Contaminants (such as rust and paint) have a much higher absorption rate for specific wavelengths of laser light than the substrate material (such as metal).

Instantaneous Reaction: The contaminant layer absorbs a large amount of laser energy in a very short period of time, causing a rapid increase in temperature, resulting in vaporization, ablation, or instantaneous expansion and delamination.

Substrate Protection: The substrate material absorbs little laser energy, resulting in minimal temperature increase and, therefore, no damage.

Advantages of fiber laser rust remover

Non-contact & Non-abrasive:

This eliminates the physical contact with the workpiece, completely avoiding the scratches, deformation, or stress damage caused by traditional mechanical cleaning methods (such as grinding and sandblasting). It is particularly suitable for precision parts, molds, artifacts, and electronic components.

High Precision & Selectivity: Precisely control the spot size (micrometer level) and energy to achieve micro-area cleaning, removing only the targeted contaminants while leaving the substrate intact.

Eco-friendly & Clean:

No Chemical Solvents Required: Eliminates the costs and risks of using, storing, and handling toxic chemicals.

No Consumables: Eliminates the continuous consumption of grit, abrasive media, and other materials.

Minimal Waste: Produces primarily gaseous or fine particulate pollutants, which are easily collected and treated by efficient dust removal systems, complying with environmental regulations.

Versatile & Easy to Operate:

Processes a wide range of materials: metals (steel, aluminum, copper, titanium), composites, stone, ceramics, rubber, and more.

It removes a wide range of contaminants, including rust, mill scale, paint/coatings, oil/grease, carbon deposits, weld slag/oxidation color, mold release agents, and patina from historical artifacts.

It's suitable for a wide range of applications, from heavy machinery restoration to precision aerospace component cleaning. One solution, unlimited applications.

The portable device offers flexibility for on-site use (e.g., onboard ships and large equipment maintenance).

Suitable for Automation: Easily integrates with robotics and CNC systems for fully automated, highly consistent cleaning processes, improving production line efficiency.

Lower Operating Costs & ROI:

While the initial investment is higher, the elimination of ongoing consumables, chemicals, waste disposal, equipment wear and maintenance, and high environmental compliance costs significantly reduces project downtime and labor costs. It delivers consistent, high-quality cleaning results from batch to batch, resulting in a high return on investment and ongoing cost savings.

How to Choose the Right fiber Laser Cleaning Machine?

Purchasing a laser cleaning machine is a significant investment and requires a comprehensive evaluation based on your specific needs:

Define Your Primary Application:

What is the cleaning objective? (Rust removal? Paint stripping? Oil removal? Oxidation removal? Antique restoration? Mold cleaning?)

What is the material being cleaned? (Steel? Aluminum alloy? Copper? Composite? Stone?)

Contaminant type and thickness? (Thin paint layer? Thick rust? Stubborn carbon deposits?)

Cleaning accuracy requirements? (Rough cleaning of large areas? Micron-level fine finishing?)

Cleaning efficiency requirements? (Small batches? High-volume production lines?)

Working environment? (Fixed workshop? Mobile? Space constraints?)

Click on our other articles for more information: Choosing the Right Laser Welding Machine

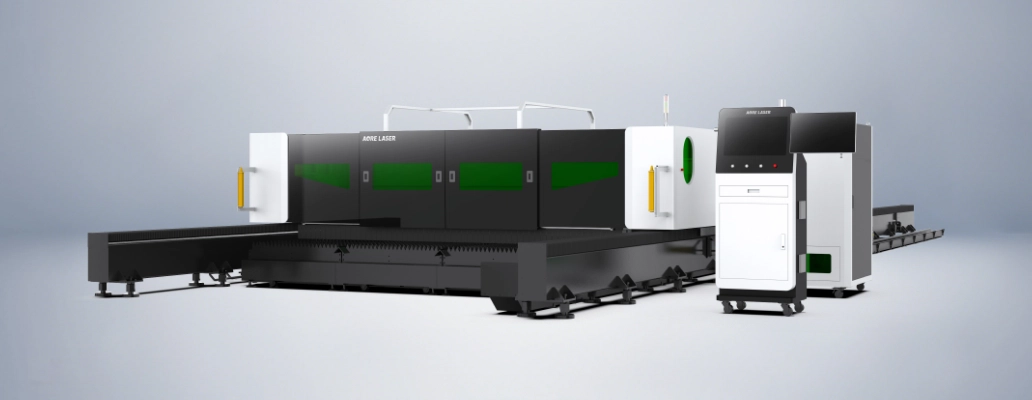

About AORE laser cleaning machine:

LC Series Handheld Laser Cleaning Machine: Efficient · Non-Destructive Cleaning · Intelligent

High-Stability Laser Source

Delivers consistent, high-efficiency performance, ensuring stable machine operation

Intelligent Control System

Supports parameter customization to accommodate various materials and cleaning process requirements.

Handheld Operation Head

Compact and ergonomic design offers flexibility for multi-scenario applications and supports agile, on-site manufacturing needs.

Professional Cleaning System

Integrates multiple cleaning modes with one-click smart operation for efficient and simplified cleaning tasks.

All-in-One Functional System

Integrated with welding, cutting, cleaning, and weld seam cleaning, it offers easy operation and meets the needs of diverse application scenarios.