Laser Welding Machines: A Complete Guide to Cost, Strength, and Selection

2025-11-13

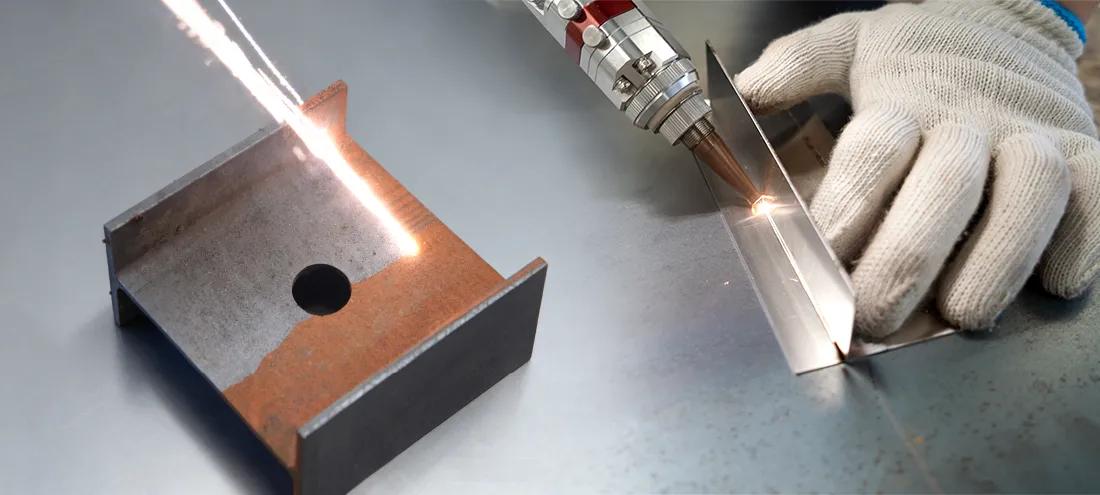

Laser welding technology represents the future of high-precision, high-efficiency joining. Compared to traditional welding methods, laser welding achieves a perfect combination of minimal heat-affected zone, extremely high welding speed, and superior weld quality through a highly concentrated energy source. This guide will directly answer your core questions about strength, cost, and performance, and help you gain a comprehensive understanding of different types of laser welding equipment.

1. Are Laser Welding Machines Really Good?

When people ask, "Are laser welding machines any good?", they want to know their actual value. The answer is yes; the advantages of laser welding machines are revolutionary, mainly reflected in:

Exceptional Precision: The laser beam can be precisely controlled to achieve micron-level welding, suitable for tiny and complex parts.

Extreme Speed and Efficiency: Welding speed is several to tens of times faster than traditional methods, significantly increasing productivity.

Beautiful Welds: The weld formation is beautiful and smooth, requiring little or no post-processing.

Minimal Heat Affected Zone: Concentrated heat minimizes the overall thermal impact on the workpiece, preventing deformation and changes in material properties.

Non-contact processing: Non-contact welding, no tool wear, suitable for fragile materials.

2. Main Types of Welding Machines

Choosing the right welding machine for your business is crucial. Here are four of the most common welding machine types to help you make a quick decision.

2.1. Electric Arc Welding Machine

Key Features: Simple equipment, low cost, flexible operation, suitable for outdoor work.

Applicable Scenarios: Construction sites, pipeline repair, steel structure installation, etc.

2.2. MIG/MAG Gas Shielded Welding Machine

Key Features: Fast welding speed, high efficiency, easy to learn and automate, aesthetically pleasing welds.

Applicable Scenarios: Automotive manufacturing, metal furniture, mass production of mechanical parts.

2.3. TIG Argon Arc Welding Machine

Key Features: High welding precision, optimal weld quality, wide range of weldable materials (e.g., stainless steel, aluminum).

Applicable Scenarios: Precision instruments, pipeline welding, aerospace, food-grade equipment.

2.4. Laser Welding Machine

Core Features: Extremely high speed, minimal deformation, high degree of automation, representing high-end manufacturing.

Applicable Scenarios: Power batteries, consumer electronics, medical devices, and automotive parts.

3. How Strong is Laser Welding Machine? Compared to Traditional Welding

Is laser welding as strong as MIG? This is a crucial question. The answer is: In most cases, a properly designed laser weld has strength equal to or better than a MIG (gas shielded metal arc) weld.

Strength Comparison Analysis:

Deeper and Narrower Welds: Laser welding has an extremely high depth-to-width ratio, enabling deeper penetration while requiring significantly less heat input than MIG welding.

Smaller Heat-Affected Zone: Laser welding concentrates heat in a very small area, maximizing the preservation of the material's original strength and reducing the risk of deformation.

Weld Consistency: The laser welding process is controlled by robots or precision machine tools, avoiding the uneven welding defects that may occur in manual MIG welding, thus ensuring a consistently high-strength connection.

4. Comprehensive Cost Analysis of Laser Welding Machines: Investment and Return

Cost is at the heart of the decision-making process. We need to distinguish between two concepts: equipment purchase cost (How much does a laser welding machine cost?) and overall operating cost (How much does laser welding cost?).

4.1 Laser Welding Machine Cost

The price range for laser welding machines is wide, mainly depending on the type, power, and configuration.

Hanheld laser welding machine price: $4300 - $9800

Automatic laser welder machine price: $12000 - $17000

Robot fiber laser welding machine price: $48000 - $58000

4.2 Overall Operating Cost

In the long run, the overall cost of laser welding may be far lower than that of traditional welding:

Labor Costs: Simpler operation, especially handheld welding, requiring no top-tier technicians and with shorter training times.

Post-processing Costs: Almost no deformation, saving significant time and materials spent on correction, grinding, and polishing.

Energy Costs: Fiber lasers have high electro-optical conversion efficiency (>30%), making them more energy-efficient than MIG welders (~60%).

Material Efficiency: Precise welding reduces the consumption of welding wire (if wire feeding is required) and shielding gas.

Efficiency Improvement: Faster speed and higher output per unit time reduce the cost per piece.

Conclusion: Although the initial investment is higher, laser welding brings significant returns on investment in the long run by saving manpower, time, and materials.

5. How to Choose the Right Laser Welding Machine for You?

Choosing the right equipment depends on your specific needs. First, we need to understand what a metal laser cutting machine is, the differences and advantages of fiber laser welding machines over traditional welding methods; second, we need to understand the precautions for selecting a laser welding machine; finally, choose a machine that suits your needs and budget.

6. FAQ

Q1: Is a handheld laser welding machine safe?

Very safe. The equipment is equipped with multiple safety features, including an emergency stop button, laser safety goggles, and anti-accidental touch design, ensuring operator safety.

Q2: What materials can the laser welding machine weld?

It has a wide range of capabilities, including but not limited to: carbon steel, stainless steel, aluminum, copper, titanium alloys, and other common metals and their alloys.

Q3: What power do I need?

Power depends on the material thickness. For welding stainless steel up to 3mm thick, a 1500W handheld laser welding machine is sufficient; however, for deep penetration welding or high-speed welding, a fiber laser welding machine of 2000W or higher is required.