Factors affecting the cutting effect of laser metal cutting machine

2025-05-10

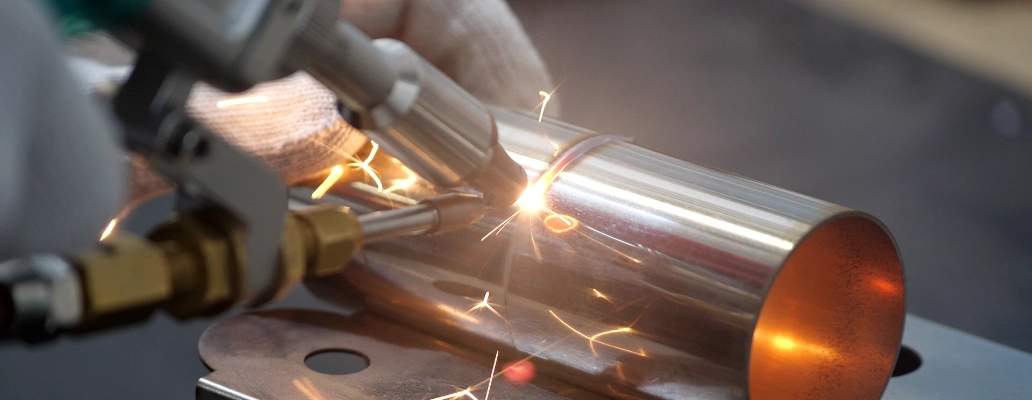

The cutting effect of the laser metal cutting machine will be affected by many factors, such as auxiliary gas pressure, laser power, cutting speed, focal position, etc. Below, Aore Laser will give you detailed answers to the above four factors

The influence of auxiliary gas pressure

In laser cutting processing, the auxiliary gas pressure plays a role in blowing away slag, cooling materials, and assisting combustion. Auxiliary gases include oxygen, compressed air, nitrogen, and inert gases.

Oxygen can participate in metal combustion, which can improve laser metal cutting machine cutting efficiency and is suitable for cutting most metals; inert gas and air are suitable for cutting some metal materials (such as aluminum alloys) and non-metallic materials, and can prevent material combustion.

Influence of laser fiber cutting machines laser power

Laser power has a great influence on cutting speed, kerf width, cutting thickness and cutting quality. The laser fiber cutting machines power size depends on the material properties and cutting mechanism. For example, materials with high melting point (such as alloys) and high reflectivity of the cutting surface (such as copper and aluminum) require a larger laser power.

Aore Laser reminds you that there is a laser power for the best cutting quality in laser cutting processing. Below this laser power, it may not be cut through or slag may appear; above this power, it will be overburned.Influence of cutting laser metal cutting machine speed

The ideal cutting speed will make the cutting surface present a relatively smooth line, and the material section will be smooth and burr-free. When the auxiliary gas pressure and laser power are constant, the cutting speed and the kerf width show a nonlinear inverse relationship. When the laser metal cutting machine cutting speed is relatively slow, the laser energy will act on the kerf for a longer time, which will lead to an increase in the kerf width, or the kerf below will be too wide, and the cutting quality and production efficiency will be greatly reduced.

Aore Laser reminds you that if you speed up the laser metal cutting machine cutting speed, the laser beam energy will act on the workpiece for a shorter time, which will reduce the heat diffusion and heat conduction effects, and the width of the slit will also be smaller. However, when the speed is too fast, the workpiece material being cut will not be cut through due to insufficient cutting heat input.

Influence of focal position

The focal position is the distance from the laser focus to the workpiece surface, which directly affects the roughness of the cut surface, the slope and width of the slit, and the adhesion of the molten residue. If the focal position is too advanced, the heat absorbed by the lower end of the workpiece being cut will increase. Under the condition of constant cutting speed and auxiliary gas pressure, the cut material and the melted material near the slit will flow in liquid form on the lower surface, and the melted material will adhere to the lower surface of the workpiece in a spherical shape after cooling; if the position lags, the heat absorbed by the lower end of the cut material will decrease, so the material in the slit cannot be completely melted, and some sharp and short residues will adhere to the lower surface of the plate.

Aore Laser reminds you that under normal circumstances, the laser fiber cutting machines focal position should be on the workpiece surface or slightly below, but different materials have different requirements. When cutting carbon steel, the cutting quality is better when the focus is on the plate surface; and when cutting stainless steel, the focus should be about 1/2 of the plate thickness for better results.