Tube laser cutting machine: Everything You Need to Know

2025-11-27

In manufacturing, laser tube cutting machines have revolutionized traditional processing methods. Using a high-energy-density laser beam, laser tube cutting machines can precisely process complex shapes, significantly improving production efficiency and product quality.

What is a Laser Tube Cutting Machine?

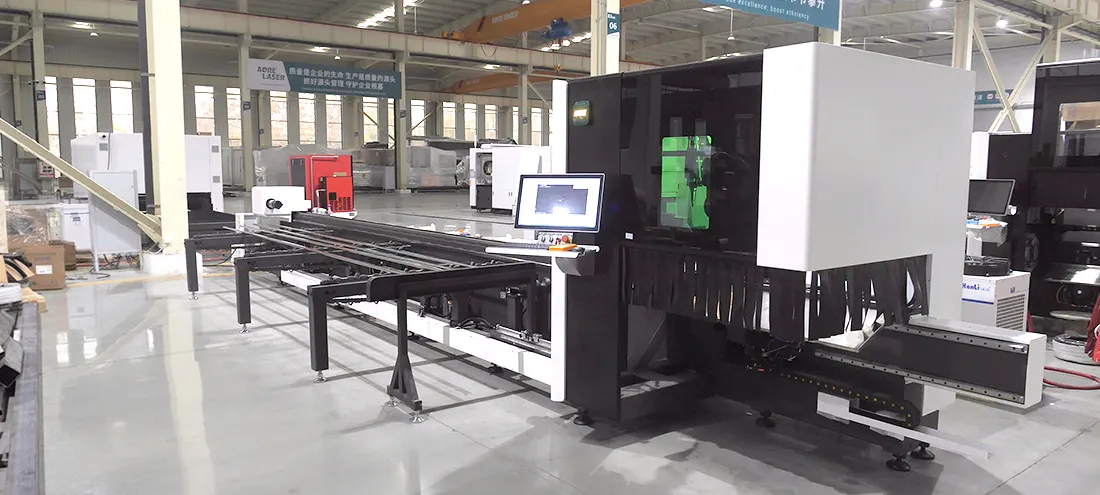

A tube laser cutting machine (also called laser tube cutting machine or laser cutting machine for tube) is an automated device specifically designed for cutting metal tubes, integrating laser technology, a CNC control system, and precision mechanics designed to cut metal pipes and profiles with high precision.

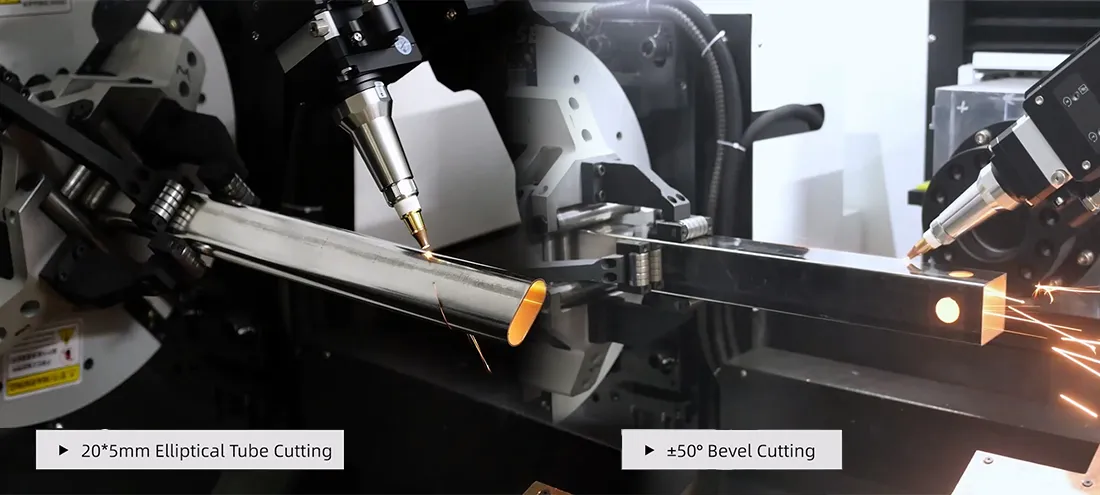

It uses a focused laser beam to perform cutting, beveling, slotting, drilling on round tubes, square tubes, rectangular pipes, oval tubes, and other customized profiles.

Compared to traditional sawing or mechanical cutting, laser tube cutting machines offer advantages such as faster speed, higher precision, higher efficiency, and full automation.

Core Working Principles

A modern CNC laser tube cutting machine operates based on three core mechanisms:

Core Working Principles

A modern CNC laser tube cutting machine operates based on three core mechanisms:

1. High-Energy Laser Source

Fiber laser power:1 .5kW – 60kW+

Cuts carbon steel, stainless steel, aluminum, iron, brass, copper

Stable beam quality ensures smooth kerf and minimal heat impact, reducing material waste.

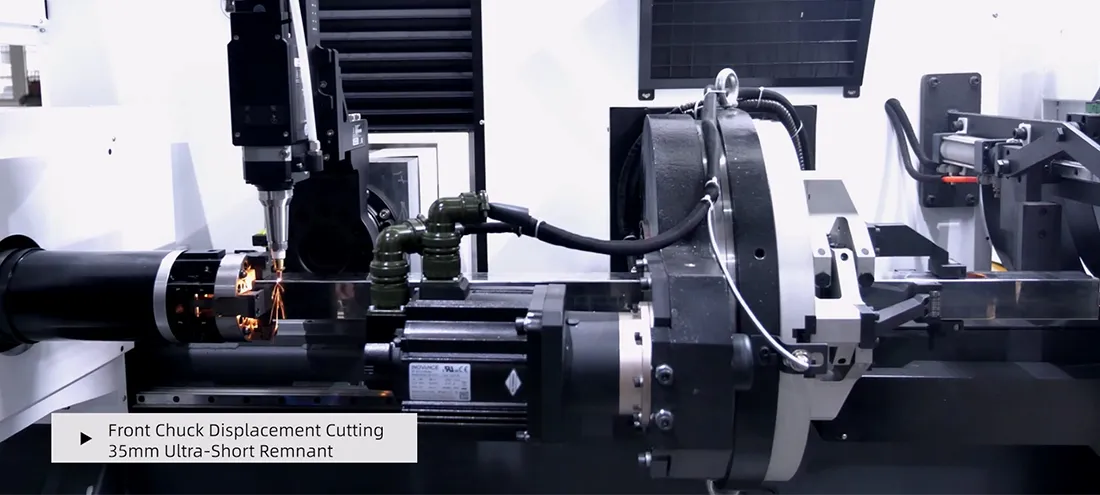

2. Rotary Chuck + Automatic Feeding(optional)

Automatically clamps and rotates the tube

Supports long tube cutting (6m–12m)

High repeatability positioning

3. Intelligent CNC System

Imports CAD/CAM drawings, Automatic nesting

Real-time compensation

Smart anti-collision and kerf optimization

This combination enables precise and repeatable cutting for industrial-scale production.

Why Choose a Tube Laser Cutting Machine?

1. High Precision

Laser cutting accuracy can reach ±0.05 mm, enabling high-end fabrication. with smooth, burr-free cuts.

2. High Speed

laser tube cutting machine Up to 3–5x faster than traditional mechanical cutting. requiring no secondary processing.

3. Multi-Process Integration

One tube laser cutting machine with multiple functions, Replace drilling, sawing, milling, grinding. Processing flexibility, Can cut round pipes, square pipes, and irregularly shaped pipes.

4. Complex Shapes Made Simple

Supports: Holes, Slots, Bevel cuts, Patterns, No mold costs, Software programming allows for product switching, saving on mold costs.

5. Automation & Low Labor Cost

Automatic loading/unloading enables true unattended cutting. ntelligent material routing system maximizes material utilization.

Why Choose Our Pipe Laser Cutting Machines

Choosing a laser tube cutting machine is not just buying equipment; it's choosing an efficient and reliable partner for your business's future. Choosing Aore Laser will bring you value far exceeding your expectations:

1. Superior Cutting Precision and Perfect Quality

We use high-quality lasers and a precise control system to ensure precision in every cut. Whether it's round tubes, square tubes, irregularly shaped tubes, or channel steel, we achieve burr-free, smooth-cut, high-quality cuts.

This reduces grinding and processing steps, improves product yield, and makes your products more competitive in the market.

2. Powerful Professional Tube Cutting Software and Automation Capabilities

Our laser tube cutting machine is equipped with intelligent software specifically developed for tube cutting, offering simple and intuitive operation. It can easily handle complex shapes and efficiently perform common-edge cutting. It supports automatic loading and unloading, enabling 24/7 uninterrupted production.

This significantly reduces reliance on skilled workers, shortens programming time, reduces material waste, comprehensively improves production efficiency, and lowers unit costs.

3. Machine Stability and Durability

Aore Laser's tube cutting machine utilizes a heavy-duty bed structure and high-quality core components (such as imported German lasers, precision lead screws, and servo motors). Rigorous testing ensures stable operation even under heavy loads and prolonged periods.

This minimizes equipment failures and downtime, guaranteeing continuous operation of your production line.

4. Wide Material and Pipe Compatibility

Our laser tube cutting machine can cut various metal pipes, including carbon steel, stainless steel, aluminum alloys, and brass. It boasts a wide range of pipe compatibility, from thin tubes to large square and rectangular tubes and I-beams, offering versatility. It meets your diverse and complex production needs, improving equipment utilization and return on investment.

5. Professional and Timely Pre-sales and Global After-sales Service Network

We not only sell equipment but also provide complete solutions. From needs analysis and equipment selection to installation and commissioning, we offer professional advice. We have established a rapid-response global service system to ensure timely resolution of problems.