Applications of Metal Laser Cutting Machines - Metal Furniture Industry

2026-02-11

Metal furniture, known for its durability and recyclability, has gained popularity among consumers, particularly in regions like North America and Europe. It is increasingly becoming the mainstream choice for residential, hospitality, and office settings. Additionally, surging consumer demand for personalized designs and complex shapes, combined with market competition, compels manufacturers to overcome traditional production bottlenecks. Rapid delivery, consistent quality, and controllable costs have become the core competitive advantages for metal furniture enterprises to establish themselves in the market. Laser cutting machines serve as the key driver to overcome these challenges and advance the manufacturing upgrade of metal furniture.

Core Challenges Faced by Traditional Metal Furniture Manufacturing Processes

The core processes in metal furniture manufacturing are sheet metal cutting and shaping. However, traditional cutting methods have long been constrained by numerous pain points, hindering enterprise development.

Cost Control and Stability Pressure Coexist:

Traditional punch press processing requires custom molds, and mold replacement is necessary when switching products, leading to significant mold waste. Plasma cutting offers low precision, resulting in burrs, severe thermal deformation, and labor-intensive post-grinding processes, compromising product consistency.

Low Efficiency and Limited Flexibility:

Traditional processing methods are inefficient, often failing to meet rapid delivery demands for large-area sheet blanking and complex pattern cutting. Numerous innovative designs remain unrealized due to traditional process limitations, trapping manufacturers in low-margin OEM competition.

As personalization and rapid delivery become core market demands, laser fiber cutters emerge as the optimal solution for metal furniture manufacturers to overcome these bottlenecks through its unique technical advantages.

Core Application Scenarios of Laser Cutting Machines in the Metal Furniture Industry

The flexibility and high precision of cnc fiber laser cutters enable it to play a central role in multiple scenarios of metal furniture manufacturing.

1. Cutting Patterns on Metal Tables and Chairs

Hollow patterns and linear designs are key elements enhancing the aesthetic appeal of metal furniture. While traditional methods struggle to achieve precise hollow effects, laser cutting effortlessly processes intricate patterns on chair legs and tabletops. The smooth cut edges and precise shapes ensure products combine practicality with decorative value.

2. Rapid Customization of Personalized Furniture

Personalized customization has emerged as a major revenue driver in the metal furniture industry—many clients seek to incorporate exclusive signatures, corporate logos, unique shapes, and other elements into their furniture. Traditional manufacturing methods often struggle to meet such demands due to mold limitations or insufficient precision. Laser cutting, however, enables rapid processing of personalized elements through flexible programming control.

3. Metal Sheets for Cabinet and Frame Assembly

The assembly precision of structural components like metal cabinets and frames directly determines furniture stability and durability. Traditional cutting methods' insufficient accuracy causes dimensional deviations in parts, leading to gaps, looseness, and other issues during assembly that compromise product quality. Laser cutting's high precision minimizes dimensional errors in sheet metal components, ensuring perfect fit for assembly requirements.

How to Select the Right Fiber Laser Cutter for Metal Furniture Operations?

Faced with numerous laser cutters on the market, metal furniture enterprises should align their choices with specific operational needs, focusing on the following key points to avoid blind investments:

1. Identify Core Processing Materials: Select equipment compatible with your primary materials. Different materials present varying cutting challenges and requirements—for instance, stainless steel cutting necessitates attention to the cutter's anti-reflection capabilities.

2. Confirm Common Sheet Thickness: The thickness of frequently processed sheets directly determines the required machine power. For thin sheet processing, medium-to-low power machines suffice; for thick sheet processing, high-power machines are recommended. Consult customer service for specifics—AORE's full-power-range laser fiber cutters accommodate varying thickness requirements.

3. Match Design Complexity: For intricate patterns and detailed shapes, prioritize high-precision models to ensure cutting accuracy and detail fidelity. For simple blanking operations, cost-effective standard models are suitable.

4. Align with production capacity needs: Standard models suffice for small-batch custom work, while automated loading/unloading systems are recommended for high-volume production to boost output.

5. Balance budget and service: Equipment procurement budgets should weigh cost-effectiveness against long-term operational costs, prioritizing brands with high stability and low maintenance expenses. Comprehensive after-sales support is equally critical.

AORE's Laser Cutting Solutions for Metal Furniture Processing

Based on the above selection criteria, AORE introduces the V12 High-Speed Laser Cutting Machine for Tubes and the PU Series Fully Protected High-Speed Sheet Metal Laser Cutting Machine. These two machines precisely address the tube and sheet processing demands in metal furniture manufacturing, targeting specific production challenges across different scenarios to deliver cost-effective solutions for enterprises.

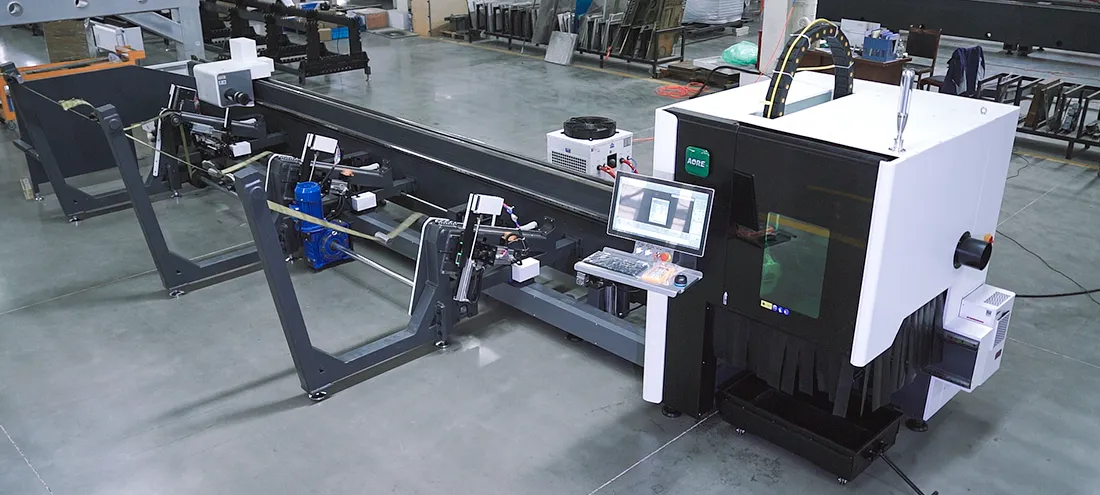

1. Tube laser cutting machine suitable for metal furniture manufacturing

For tube processing applications in metal furniture—such as table legs and frames—the AORE V12 High-Speed Tube Laser Cutter serves as an indispensable tool.

With 2G maximum acceleration and a 200r/min high-speed chuck, this machine achieves ultra-fast cutting, significantly shortening processing cycles and accelerating order fulfillment.

Its dual-support system with adaptive concave rollers minimizes vibration during high-speed tube processing. The dynamic support design ensures stability throughout long-tube processing, guaranteeing cutting precision for tighter component joints and enhanced furniture structural integrity.

The front chuck design limits tailstock length to 30mm, minimizing material waste and directly reducing raw material costs—perfectly aligned with metal furniture manufacturers' demand for cost control.

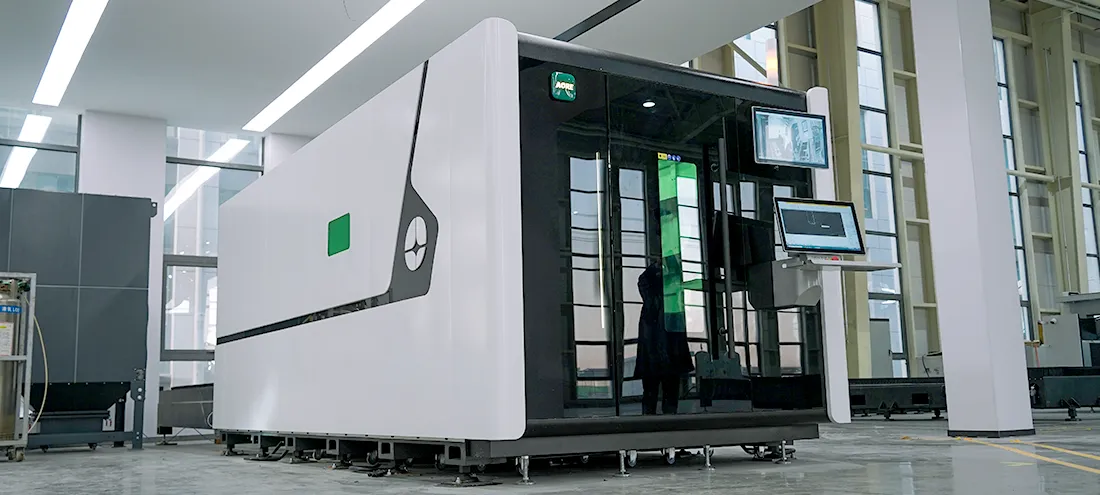

2. Sheet metal laser cutter suitable for metal furniture manufacturing

For sheet metal applications in metal furniture—such as screens, partitions, cabinet panels, and decorative patterned sheets—the PU Series fully-enclosed high-speed sheet metal laser cutter delivers efficient, precise processing that comprehensively boosts production efficiency.

This series operates at speeds up to 180m/min, boosting production efficiency by 50%-80% compared to traditional sheet cutting equipment, effortlessly handling peak season order demands.

Regarding precision, the PU series fiber laser cutting machine can precisely cut complex artistic patterns and intricate hollow shapes, perfectly meeting the processing needs of high-end custom furniture such as metal screens and decorative walls, directly improving product quality and aesthetics.

Addressing dust concerns during metal furniture panel cutting, the PU series features a zoned dust extraction system with ≥95% efficiency. An optional enclosed downward suction dust collector effectively captures cutting dust and fumes, optimizing the production environment and safeguarding operator health. The optional intelligent safety light curtain system provides real-time, all-angle protection, ensuring zero-risk production and meeting corporate safety requirements.

Both machines build upon AORE's R&D team's technical expertise, catering to all scenarios in metal furniture manufacturing. Enterprises can flexibly select models based on their primary production needs—whether focused on tube processing, sheet processing, or both—along with material type, thickness, and capacity planning. AORE's professional team also offers one-on-one consultation services to help businesses precisely match equipment requirements.

Advantages of CNC Laser Cutters in the Metal Furniture Manufacturing Industry

Compared to traditional cutting methods, laser cutting offers comprehensive advantages in metal furniture manufacturing—each delivering concrete cost savings and efficiency gains for businesses.

No Mold Dependency, Lower Customization Costs: For the metal furniture industry's common small-batch custom orders and personalized requests, steel laser cutting machines require no molds. Simply import design drawings into the system, and processing begins within minutes. This saves substantial economic and time costs while significantly lowering customization barriers.

Effortless Cutting of Complex Shapes: Laser cutting effortlessly handles intricate curves, cutouts, and artistic patterns, precisely replicating any design blueprint. This frees metal furniture designers from compromising due to process limitations, enabling direct realization of innovative designs and substantially boosting product competitiveness.

Smooth, burr-free edges elevate product quality: Laser cuts deliver high precision with smooth, burr-free edges and minimal heat-affected zones, preventing material deformation. Cut components can proceed directly to assembly, eliminating the trimming steps required in traditional processes. This not only reduces labor costs but also ensures consistent appearance and stable quality for every product, helping businesses build a premium brand image.

High material utilization reduces waste: Laser cutting machines feature intelligent nesting systems that optimize layout based on sheet dimensions, maximizing raw material usage. Compared to traditional cutting methods, this significantly improves material utilization rates. This advantage directly lowers raw material costs and boosts corporate profit margins.

Conclusion

Amid market trends demanding personalization, rapid delivery, and high quality, steel laser cutting machines not only overcome design limitations of traditional processes, boost production efficiency, and reduce overall costs, but also empower enterprises to stand out from homogeneous competition. They facilitate upgrades to higher-end segments of the industrial chain, enabling companies to gain global market competitiveness through technological advancement.

AORE laser cutting machines, with its precise cutting accuracy, high-efficiency production capacity, and comprehensive customized solutions, stands as the ideal partner for metal furniture manufacturers. Whether you need to push design boundaries, boost production efficiency, reduce operational costs, or optimize product quality, AORE delivers tailored laser cutting solutions. Take action now and unlock new possibilities in metal furniture manufacturing!