Automotive Industry

The automotive industry is undergoing a profound transformation. The growing use of lightweight materials, rapid adoption of electrified platforms, and the shift toward multi-variety, low-volume production are driving an urgent need for high-speed, high-precision, and intelligent manufacturing technologies. AORE Laser provides end-to-end laser cutting and welding solutions for complete vehicle manufacturing, empowering efficient, precise, and flexible production.

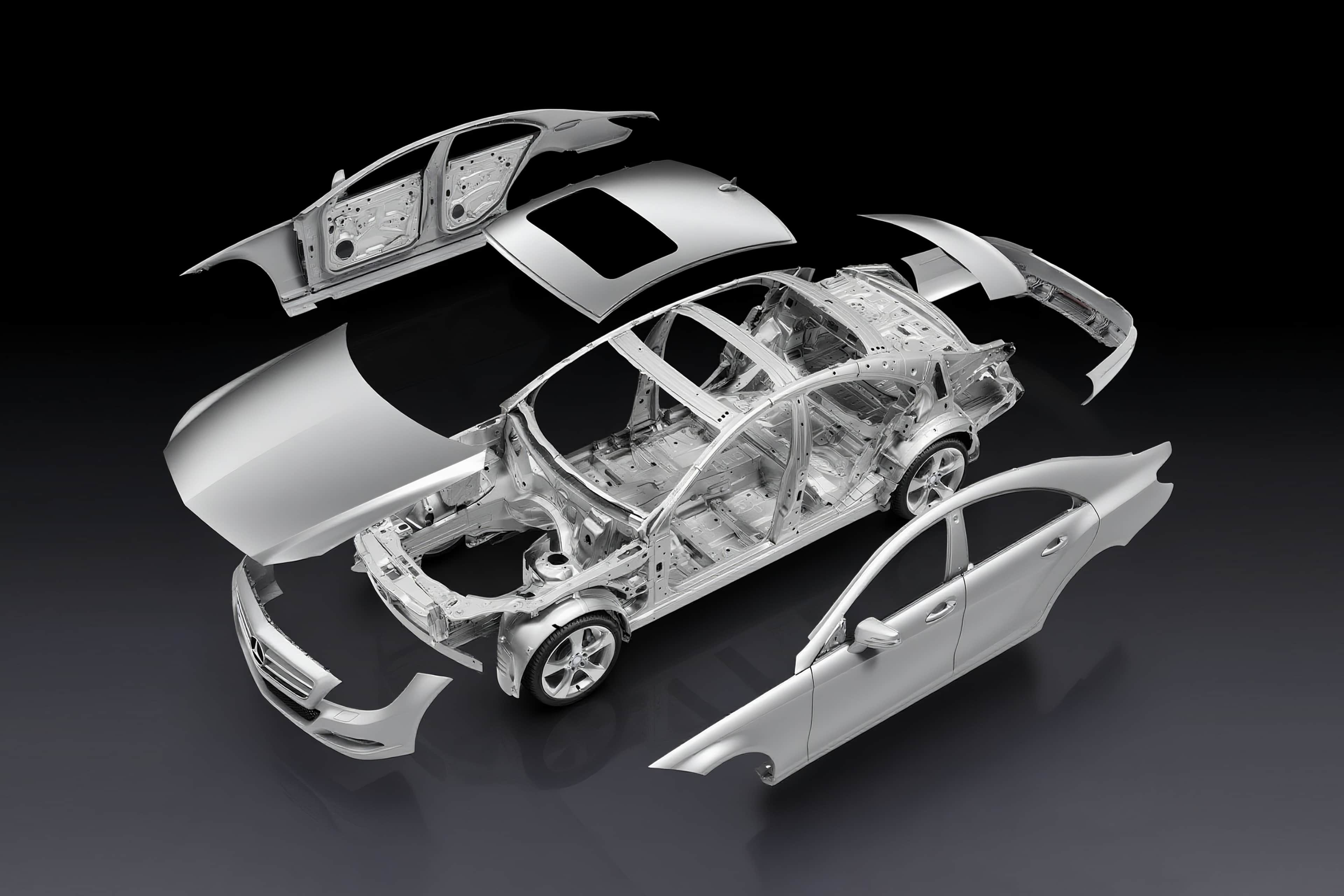

Body Panels and Sheet Metal Parts

Challenge:

In automotive manufacturing, body panels and sheet metal components demand exceptional precision and surface quality. The complexity of large, contoured structures increases the difficulty of forming and cutting, while lightweight design trends require compatibility with diverse materials. Additionally, growing model variety accelerates production changeovers, placing greater demands on flexible manufacturing and process consistency.

Solution:

AORE’s laser solutions enable precise, burr-free cutting of diverse and complex body panels and sheet metal components across different vehicle models. Even large-format sheet parts are handled with ease through customizable cutting platforms, ensuring stable, high-precision processing. High-speed operation reduces cycle times and delivers consistent edge quality, enhancing the overall finish of exterior components.

Chassis Frames and Tubular Structures

Challenge:

Chassis and structural frame manufacturing in the automotive industry relies heavily on high-strength tubes and complex profiles, demanding greater cutting power, precision, and consistency. As lightweighting and safety requirements grow, processing thick-walled and intricate components becomes increasingly challenging. Moreover, large production volumes and strict standards make traditional methods inefficient and costly, falling short of today’s flexible manufacturing demands.

Solution:

AORE’s tube laser cutting systems are equipped with multiple processing technologies to handle various tube types with high speed and accuracy. The solutions support efficient batch production while minimizing material waste and ensuring dimensional precision.

E-Drive

Challenge:

As NEVs move toward higher efficiency, longer range, and environmental sustainability, lightweight design becomes a key priority. The extensive use of aluminum alloys, ultra-high-strength steel, and composites imposes higher demands on laser processing performance.

Solution:

AORE’s intelligent laser processing solutions are optimized for high-efficiency cutting of reflective and lightweight materials such as aluminum alloys. Clean edge quality eliminates the need for post-processing, reducing defects and improving overall production reliability.

3D Complex Components

Challenge:

Irregular 3D geometries make batch processing difficult to control with precision.

Solution:

AORE’s 5-axis 3D laser solutions enable full 360° flexible cutting of complex shapes, significantly shortening lead times for intricate parts. The high cutting accuracy improves assembly fit and reduces the need for secondary rework.