Intelligent Control System

Supports automatic tube size detection, smart auto-focusing, fly-cutting, and efficient nesting for optimized processing.

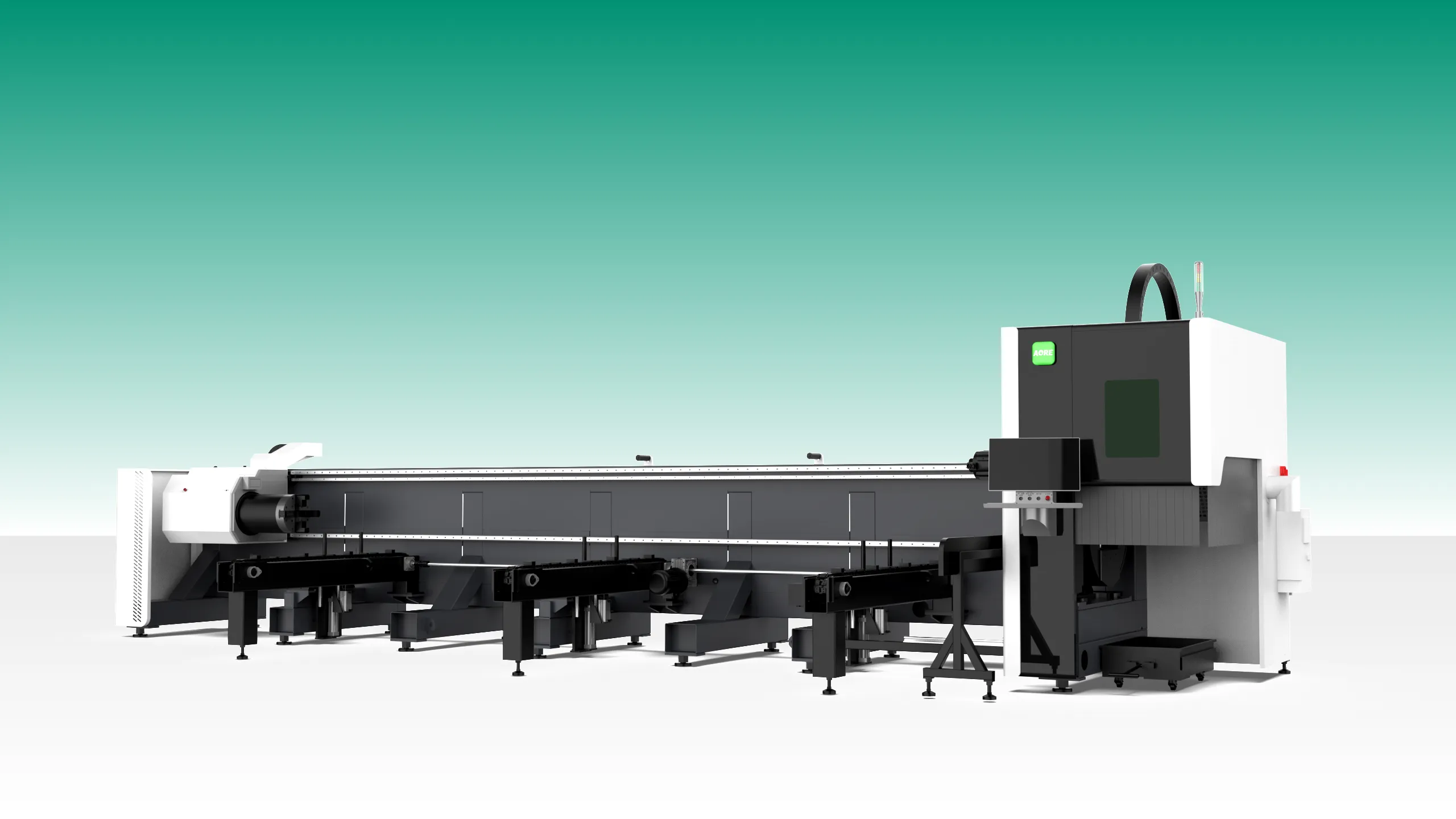

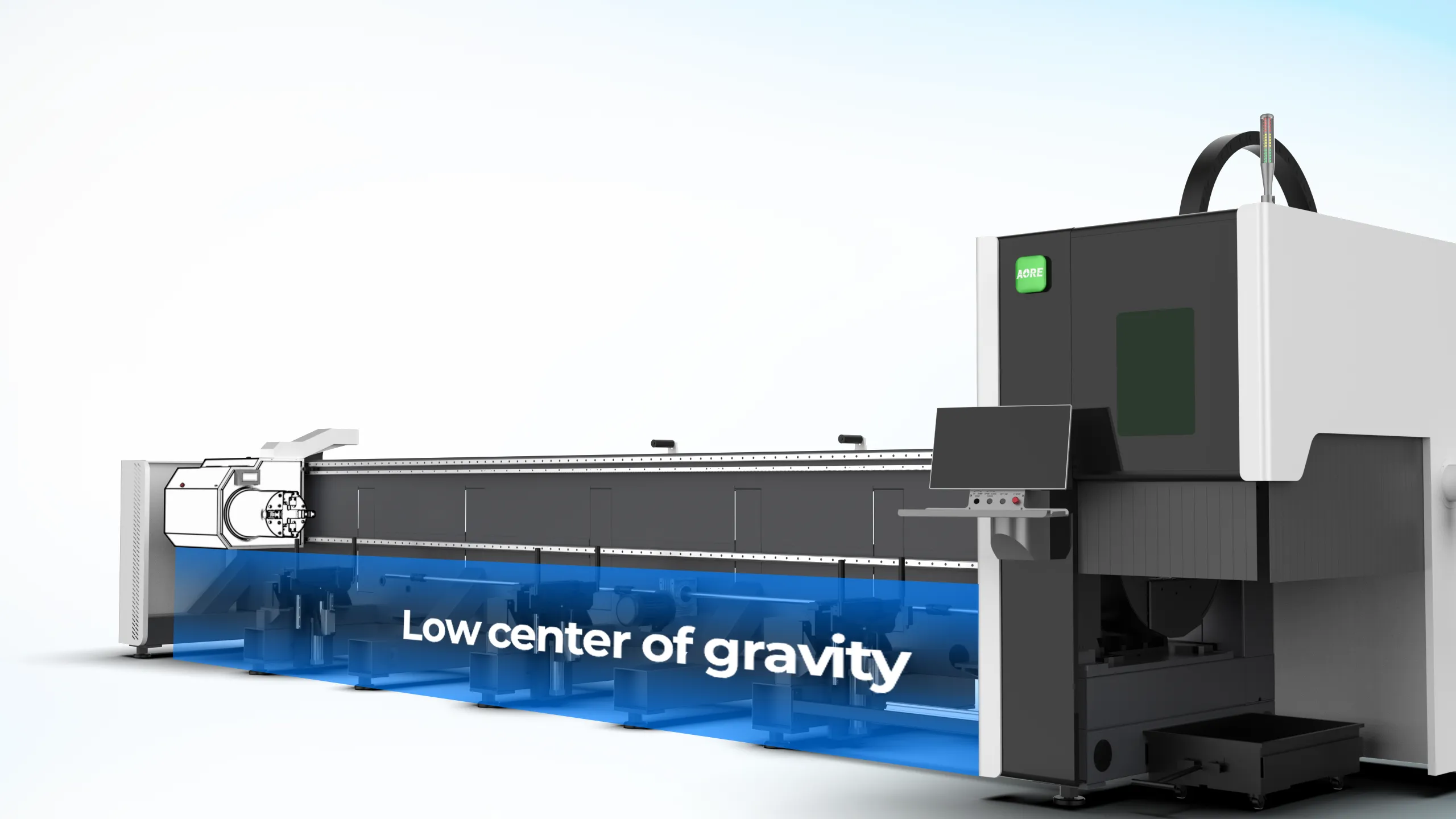

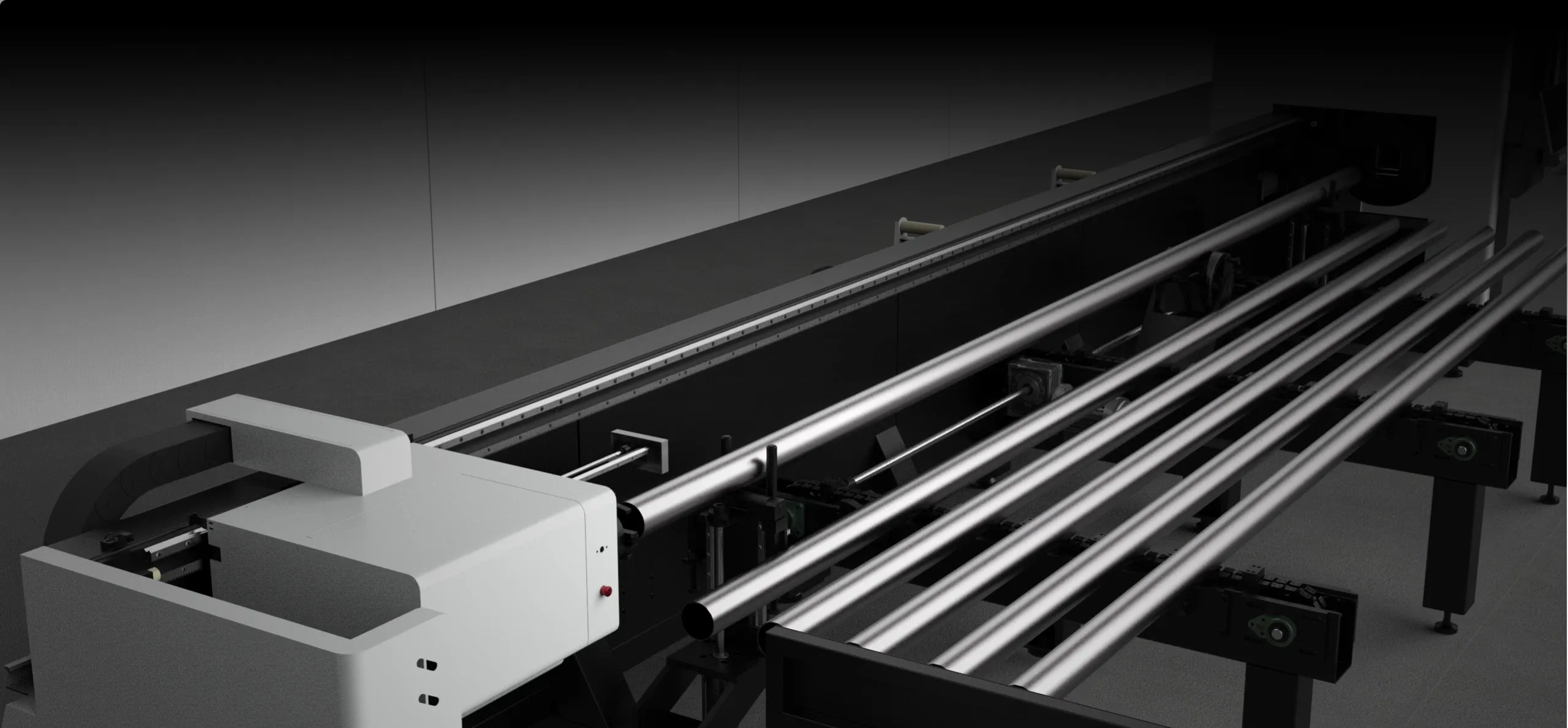

Side-Mounted Bed Frame

Lowers the center of gravity of the tube, significantly enhancing cutting stability.

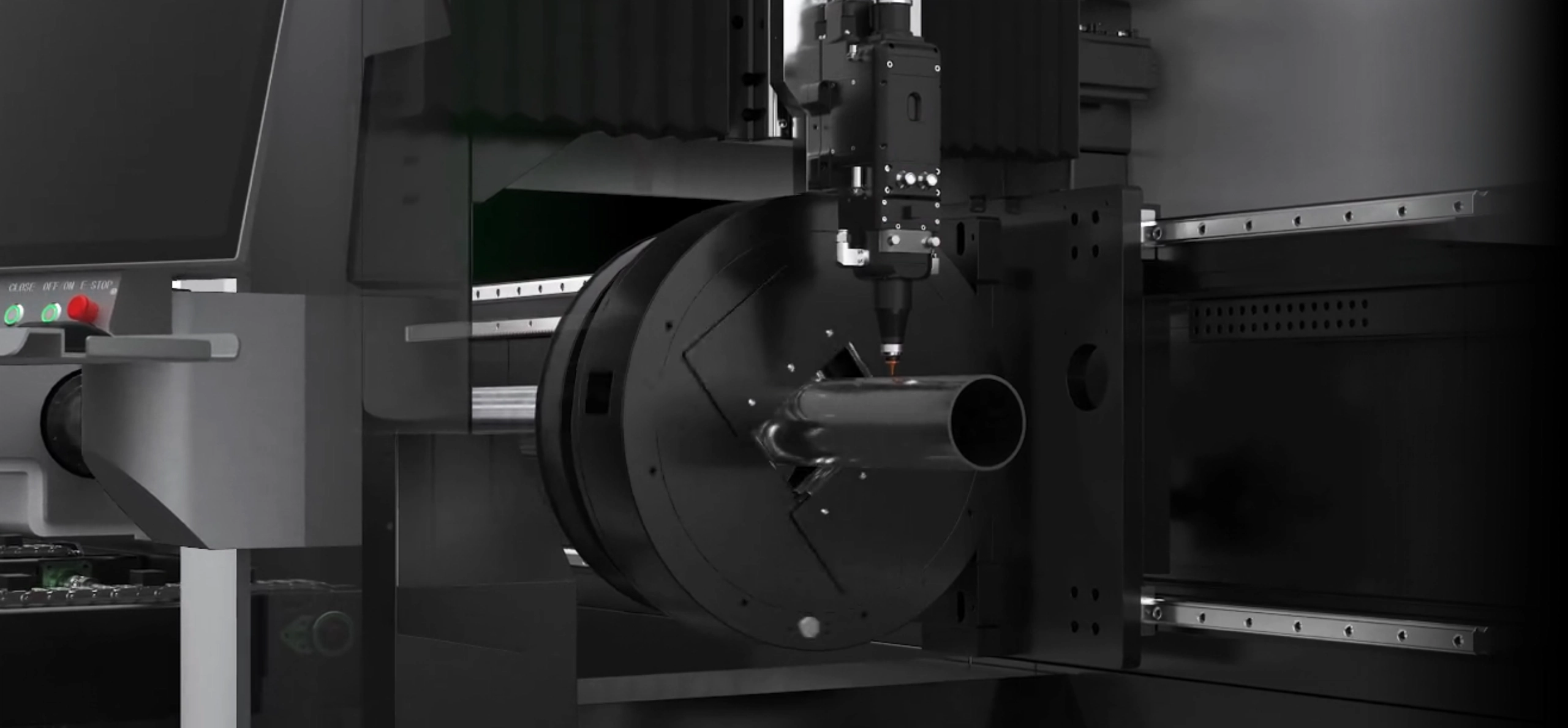

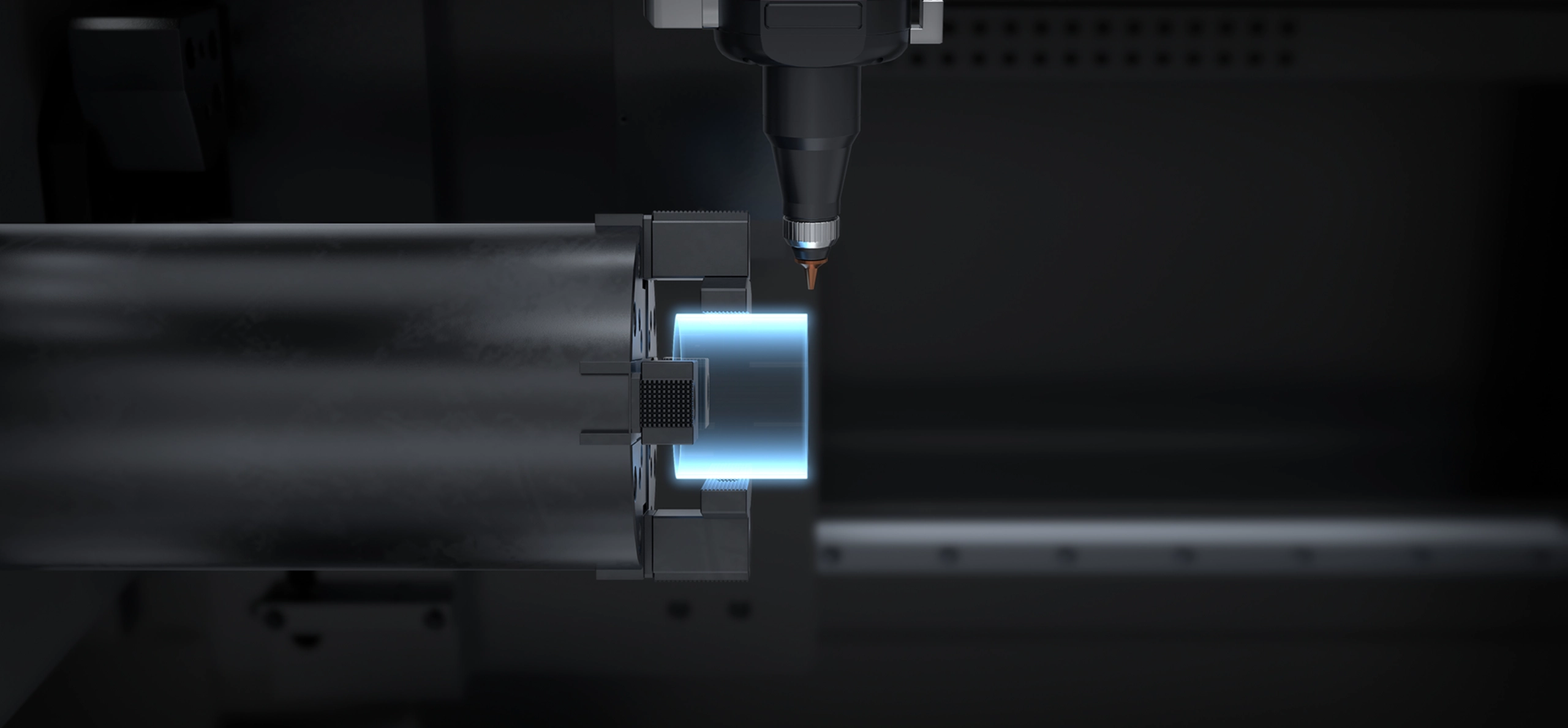

Electric Double Chucks for High Efficiency

It delivers greater transmission efficiency with a simplified design for easier disassembly and maintenance and supports intelligent identification and stable clamping of round, square, rectangular, and irregular tubes. Fast cutting response and reliable accuracy meet the demands of high-speed, high-quality production.

Forward Chuck Movement

Designed for long work-piece processing, the forward-moving chuck reduces unsupported tube length, enhancing clamping stability and cutting accuracy.

Smart Loading for Labor Savings

Equipped with an intelligent automatic loading, the machine enables fully automated material loading, significantly reducing manual intervention and boosting overall production efficiency.

Ultra-Short Scrap

Through optimized structural layout and cutting path design, the system achieves ultra-short scrap cutting, minimizing material waste. Compared to conventional solutions, it greatly improves material utilization, ideal for batch production scenarios where cost control is critical.

Intelligent Control System

Powered by a bus-type intelligent control system, the machine supports fly-cutting, smart nesting, and high-speed follow-up functions.

Applications

Steel Structure

Fitness Equipment

Metal Furniture

Construction Machinery

Pipeline Systems

Technical Parameters

| Model | TH6020 | TH6035 |

|---|---|---|

| Power | 1.5-6kW | 3-12kW |

| Processing Diameter | Φ15-Φ230mm □15*15-□230*230mm | Φ20-Φ350mm □20*20-□350*350mm |

| Max Load Capacity per Piece | 300kg | 900kg |

| Processing Length | 6300mm | 6300mm |

| Maximum Acceleration | 1.5G | 0.8G |