Choose your language

Request A Quote

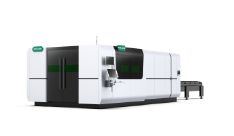

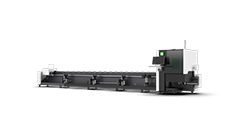

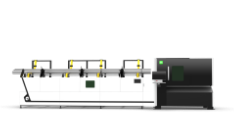

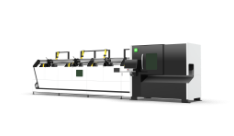

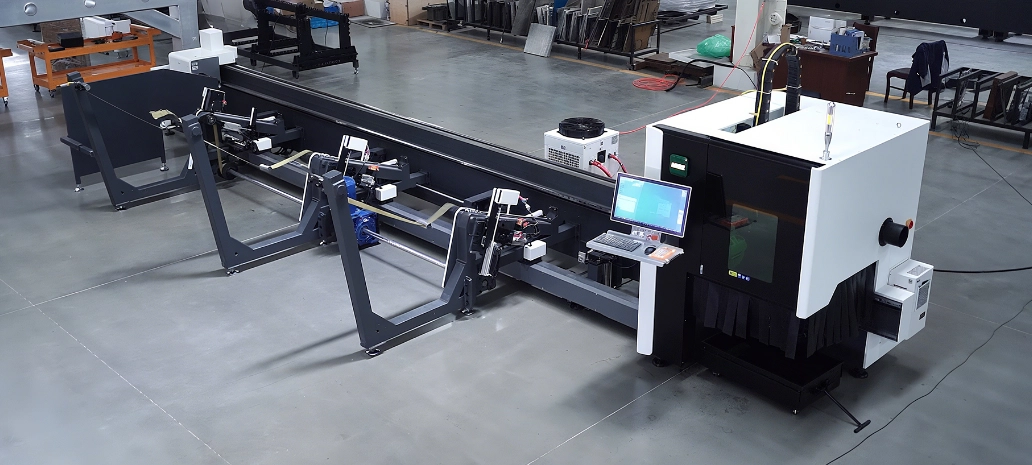

2025 High-efficiency Fiber Tube Laser Cutting Machine

Unlock a new level of productivity with the Aorelaser V12 high-speed tube laser cutting machine, In the competitive metal manufacturing industry, precision, speed, and automation are not luxuries, but necessities. If you are facing the following difficulties:

(1)Slow processing speed

(2)Unstable round/square tube cutting quality

(3)Increasing labor costs for complex profiles

The Aorelaser V12 high-speed tube laser cutting machine provides you with a solution. Designed for high precision and high efficiency, this system has completely changed the way manufacturers process structural tubes, pipes, and profiles.

Types of Tube Laser Cutting Machine:

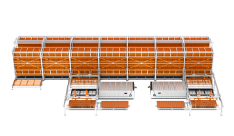

According to the classification of the number of chucks, the pipe laser cutting machine can be divided into single chuck, double chuck, three chuck and four chuck. According to the loading and unloading system, it can be divided into manual loading, semi-automatic loading and fully automatic loading.

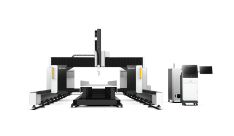

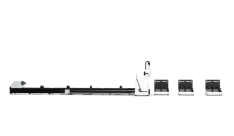

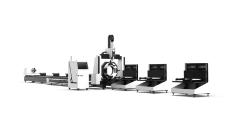

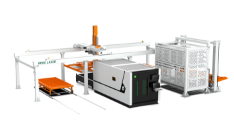

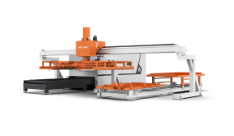

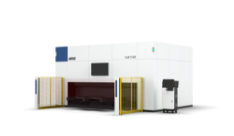

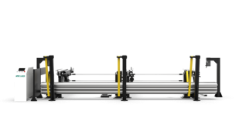

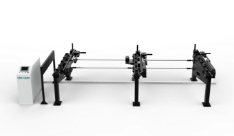

Three chuck pipe laser cutting machine:

TE Side-mounted heavy-duty laser pipe cutting machine:

Fully automatic pneumatic chuck that provides stable and efficient operation.

The automatic centering and quick clamping capabilities ensure high-speed cutting.

Incorporates a zero tail material cutting process, allowing for infinitely zero tail material cutting of heavy pipes and improving material utilization rates.

Pipe Laser Cutting machine's integral profile welded bed enhances rigidity and stability, while the automatic loading system enables safe, convenient, and efficient feeding of multiple tubes.

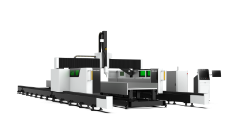

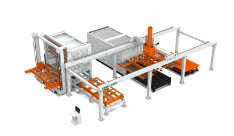

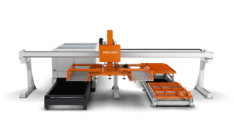

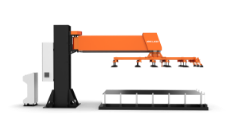

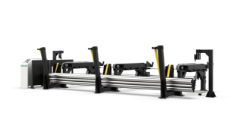

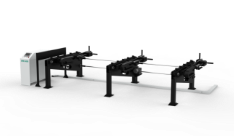

Double chuck Pipe Laser Cutting Machine:

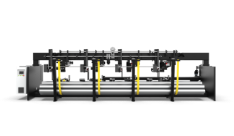

V12 high-speed tube laser cutting machine:

Ultra-Fast Cutting, Elevated Efficiency

Intelligent Support, Precise Stability

Minimal Tailing, Maximum Yield

Dynamic Support, Precision Guaranteed

About V12 high-speed fiber laser pipe cutting machine

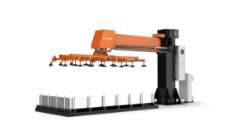

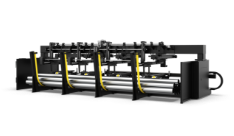

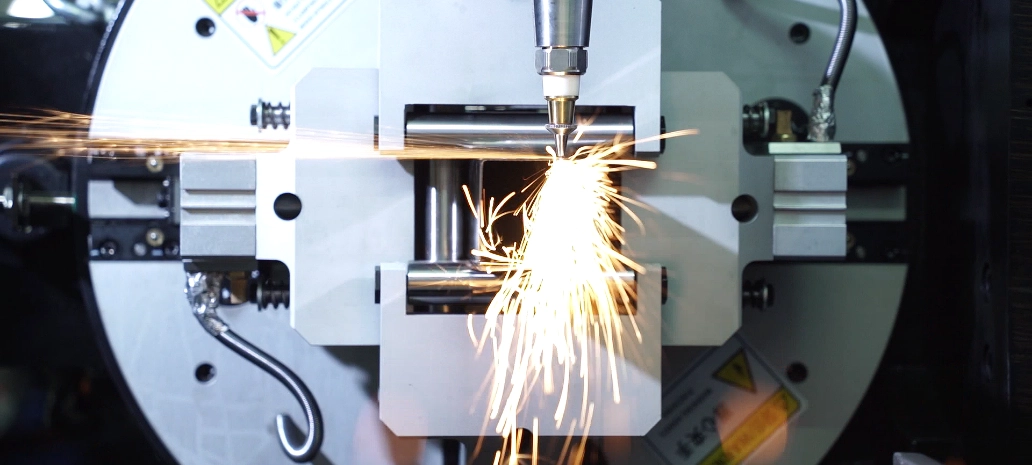

(1) 2G acceleration and 200 r/min chuck enable ultra-fast tube cutting. Shorter cycles, higher output, faster delivery.

(2) Dual adaptive and concave roller supports keep tubes steady at high speed, ensuring smooth cuts and high precision.

(3) Front-shift chuck minimizes tailing and material waste while reducing wear, boosting overall efficiency.

(4) Full-process support stabilizes long tubes during loading, cutting, and unloading, ensuring consistent accuracy.

(5) Efficient smoke and dust removal, environmentally friendly production.

(6) Provides one-key cutting function for common tube shapes such as square tube/rectangular tube/round tube/triangular tube/waist tube/flat steel, as well as some special-shaped tubes

(7) When cutting long workpieces, the chuck forward movement function is used to improve cutting accuracy, reduce chuck life loss, and achieve short tail material.

(8) Automatically adjust the focus to improve cutting effect.

Aorelaser: Your Partner in Industrial Laser Innovation

With years of laser R&D experience and a professional after-sales team, we provide:

On-site installation & operator training

24*7 after-sales service

Contact us now to get a free quote on the latest V12 machines, get a limited time discount!