Choose your language

Request A Quote

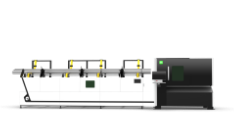

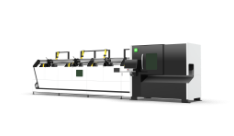

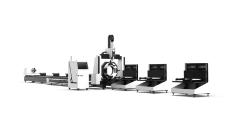

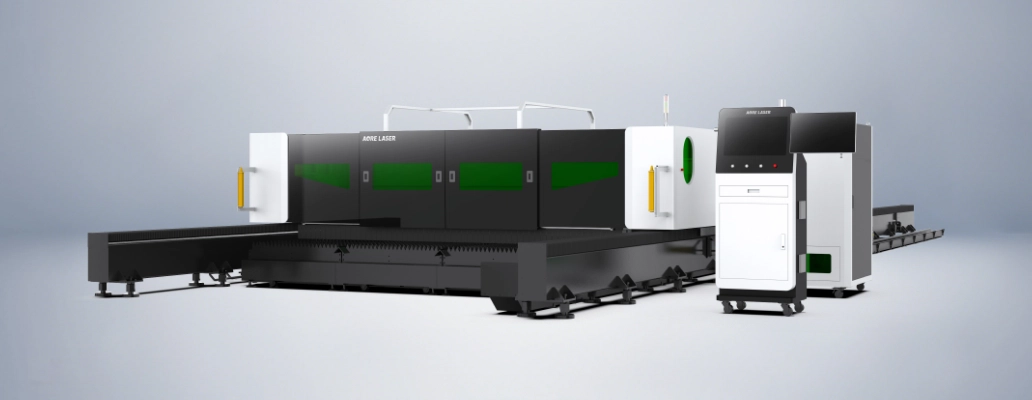

Essential Summer Maintenance for Fiber Laser Cutting Machines

As temperatures soar, your fiber laser cutter faces invisible threats that can trigger unexpected shutdowns and $10,000+ repair bills. Industry data shows over 60% of summer equipment failures stem from just two culprits: cooling system failures and condensation damage.

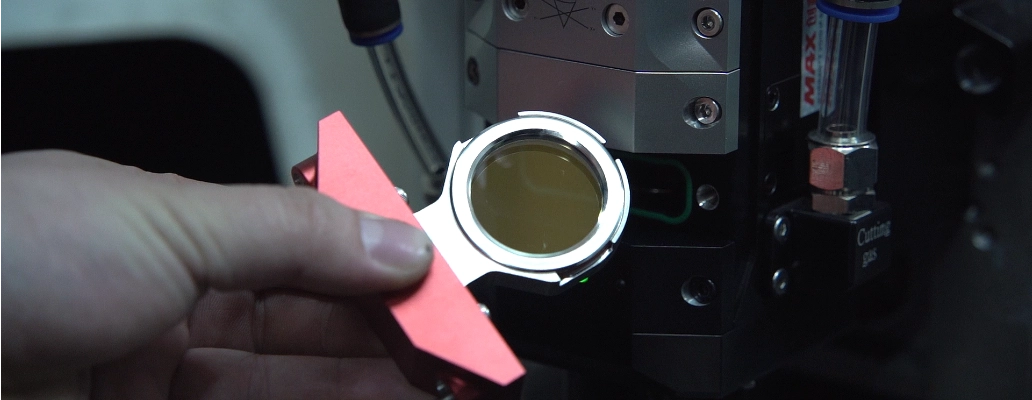

When fiber laser cutting machine is running in summer, it is easy to encounter a problem - condensation. Condensation refers to the phenomenon that when the ambient temperature drops below the "dew point temperature" of this environment, the moisture in the air gradually reaches a saturated state until water dew precipitates on the surface of the object. Condensation can cause moisture erosion of the electronic and optical modules inside the laser, causing corrosion, short circuit, failure and other problems, seriously affecting the performance and life of the laser.

Chiller maintenance tips:

Chillers are crucial to prevent laser condensation in summer, so an important measure to prevent condensation of lasers is to regularly inspect and perform daily maintenance on the chiller.

Fiber Laser Cutter Maintenance content

Before turning on the laser:

Check whether the cooling water circuit (laser cladding head and chiller) is connected normally and whether the water level is within the specified scale. If the water level is below the warning line, add cooling water.

Maintenance frequency:

once every two days

Check whether the water pipe interface has any abnormal phenomena such as leakage, bending, blockage, etc.

once every two days

Regularly remove and clean the dust screen of the chiller

Regularly clean the dust on the chiller condenser.

once every two days

Check whether the fiber laser cutting machines chiller cooling water is contaminated. If contaminated, please replace the cooling water in time.

Check whether the chiller's air inlet and outlet are ventilated smoothly to ensure that the chiller is used in a well-ventilated environment.

Regularly replace the chiller's circulating cooling water. It is recommended to use purified water or distilled water.

Real-World Impact: A Texas Case Study

A Houston metal fabricator reduced summer downtime by 78% after implementing:

Daily coolant temp/dew point checks

Quarterly chiller coil cleaning

Dual redundant chillers

Their ROI? $46,000 saved in 6 months.

Don’t let summer sabotage your productivity. A single hour of unplanned downtime costs manufacturers $260,000+ on average, Contact us for a free summer maintenance checklist to protect your fiber laser cutting machine today