Choose your language

Request A Quote

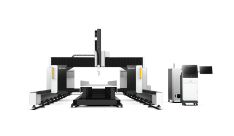

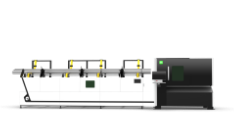

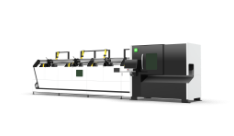

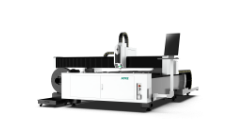

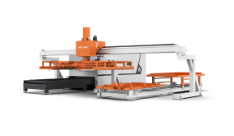

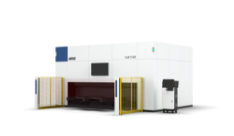

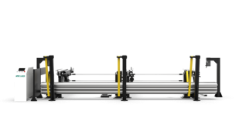

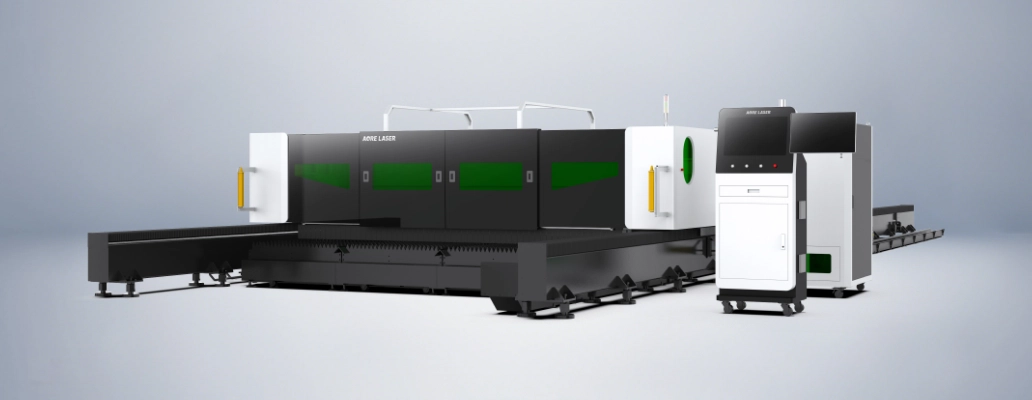

GR-H Fiber Laser Cutting Machine: Power Meets Precision for Industrial Metal Fabrication

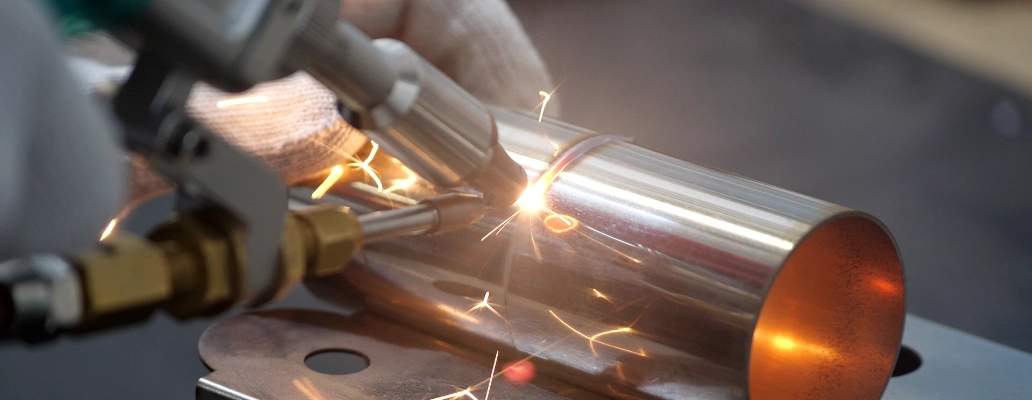

In today's competitive metal fabrication landscape, Are you looking for a machine that combines powerful power, precise cutting and efficient production? The GR-H Series CNC Fiber Laser Cutting Machines can solve it. The cnc fiber laser cutting machine is redefining what is possible for demanding sheet and plate cutting applications.

Designed for Thick Plate

At the heart of the GR-H is its high-power density laser source, which delivers extreme cutting capabilities:

Designed for Thick Plate: Easily cut thick carbon steel, stainless steel, and other ferrous metals with unprecedented performance. Maximize the scope of your projects with clean, dross-free cuts even on challenging thick plates.

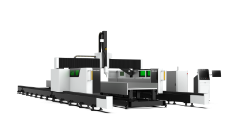

Extreme Cutting Speeds: Dramatically reduce cutting cycle times. The GR-H cuts significantly faster than lower-powered machines, especially when cutting thicker materials, increasing your shop’s output and productivity.

High-Quality Cutting: Designed to operate continuously in demanding factory environments, the GR-H fiber laser cutting machine ensures consistently high-quality results, shift after shift.

Breaking the pain points of industrial processing

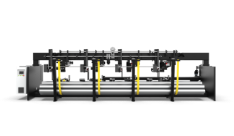

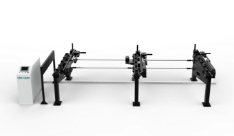

The contradiction between material diversity and equipment uniformity

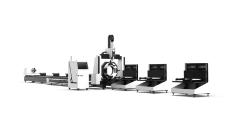

In steel structure processing, H-shaped steel, I-shaped steel, channel steel, angle steel and other profiles, as well as square tubes, round tubes and plates of different widths need to be frequently switched for processing. Traditional equipment can often only process a certain type of material, and enterprises need to purchase multiple equipment, which not only takes up a lot of plant space, but also has a high equipment idle rate. Taking bridge engineering as an example, a project may involve multiple working conditions such as profile cutting, plate beveling cutting and pipe marking at the same time, and the time consumption of equipment switching can account for up to 30% of the production cycle.

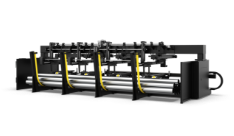

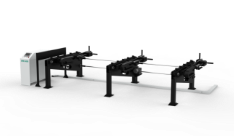

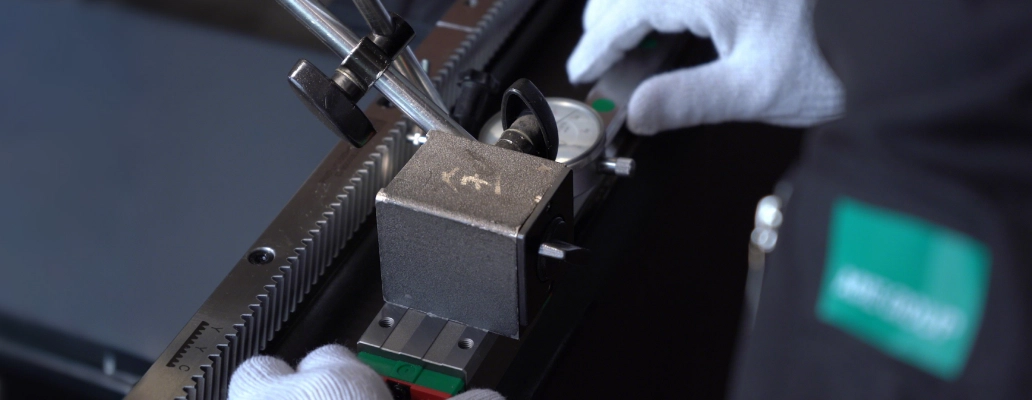

The dual challenge of efficiency bottleneck and precision error

The operating speed of traditional cutting equipment is generally lower than 50m/min. When facing the batch processing of large steel structures such as rail transit vehicle parts, the production capacity is difficult to meet the construction period requirements. At the same time, problems such as cutting misalignment and hole position deviation caused by manual positioning make the scrap rate as high as 8%-12%. Especially in the processing of key parts of engineering machinery, insufficient precision may directly affect the performance of the equipment.

Imbalance between safety protection and cost control

The lack of protection against cutting slag splash and laser radiation has led to frequent safety accidents in the workshop; when upgrading traditional equipment, the foundation reconstruction costs hundreds of thousands of yuan, and the production suspension cycle is as long as several months, which puts great pressure on small and medium-sized steel structure enterprises.

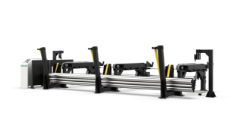

Engineered for Productivity & Uptime

The GR-H sheet metal laser cutting machine is designed to maximize your operational efficiency:

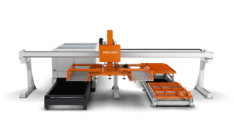

High-Speed Dynamics: Advanced servo systems and optimized acceleration ensure rapid positioning, minimizing non-cutting time.

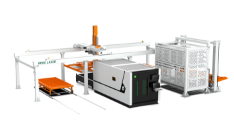

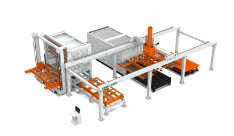

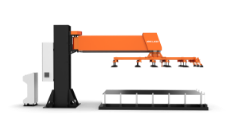

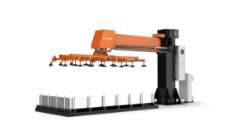

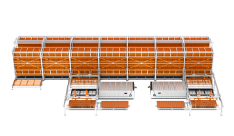

Intelligent Automation Ready: Seamlessly integrate with automated loading/unloading systems for true lights-out manufacturing potential.

Proactive Maintenance & Diagnostics: Smart monitoring systems provide real-time data and alerts, enabling predictive maintenance to minimize costly downtime.

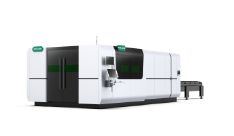

Proven Performance for Demanding Industries

Manufacturers worldwide trust the GR-H fiber laser cutting machine for critical applications in:

Construction Machinery & Heavy Equipment

Shipbuilding & Offshore Platforms

Mining & Agricultural Equipment

Pressure Vessels & Energy Infrastructure

Precision Sheet Metal Fabrication

Aerospace Composite Components

Say goodbye to wasted time and materials!

The GR-H CNC fiber laser cutting machine perfectly cuts thick plate and carbon steel with Positioning accuracy up to ±0.1mm. Maximize uptime and reduce waste. Get your custom quote!