Metal Processing Industry

Diverse tubes

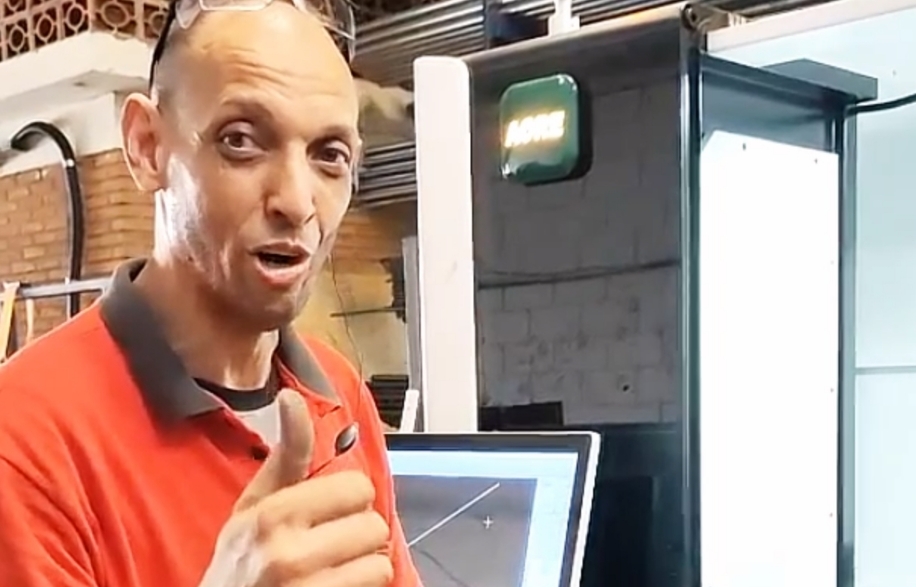

Processing small tubes with traditional methods often results in low efficiency, inconsistent quality, and high labor costs. For this São Paulo, based metal fabricator, increasing production speed without compromising a

AORE provided a tailored TM Series small tube laser cutting solution, purpose-built for high-speed, high-precision cutting of thin and small-diameter tubes. Compact in design and efficient in operation, the TM Series helped the customer streamline tube processing and achieve stable, scalable output with ease.

The introduction of AORE’s TM Series transformed the customer’s approach to small tube fabrication. Designed specifically for high-speed processing of narrow-diameter tubes, the TM Series delivered sharp, clean cuts with minimal thermal impact, ideal for producing precise, burr-free components.

With faster cutting cycles and improved consistency across batches, the customer saw immediate gains in productivity, quality, and operational efficiency. Manual handling was reduced, waste minimized, and throughput significantly increased, empowering the business to meet tighter deadlines with greater confidence.

What set AORE apart was not just the machine itself, but the end-to-end support provided. From equipment commissioning to technician training, AORE ensured a smooth onboarding process, enabling the customer to unlock value from day one.