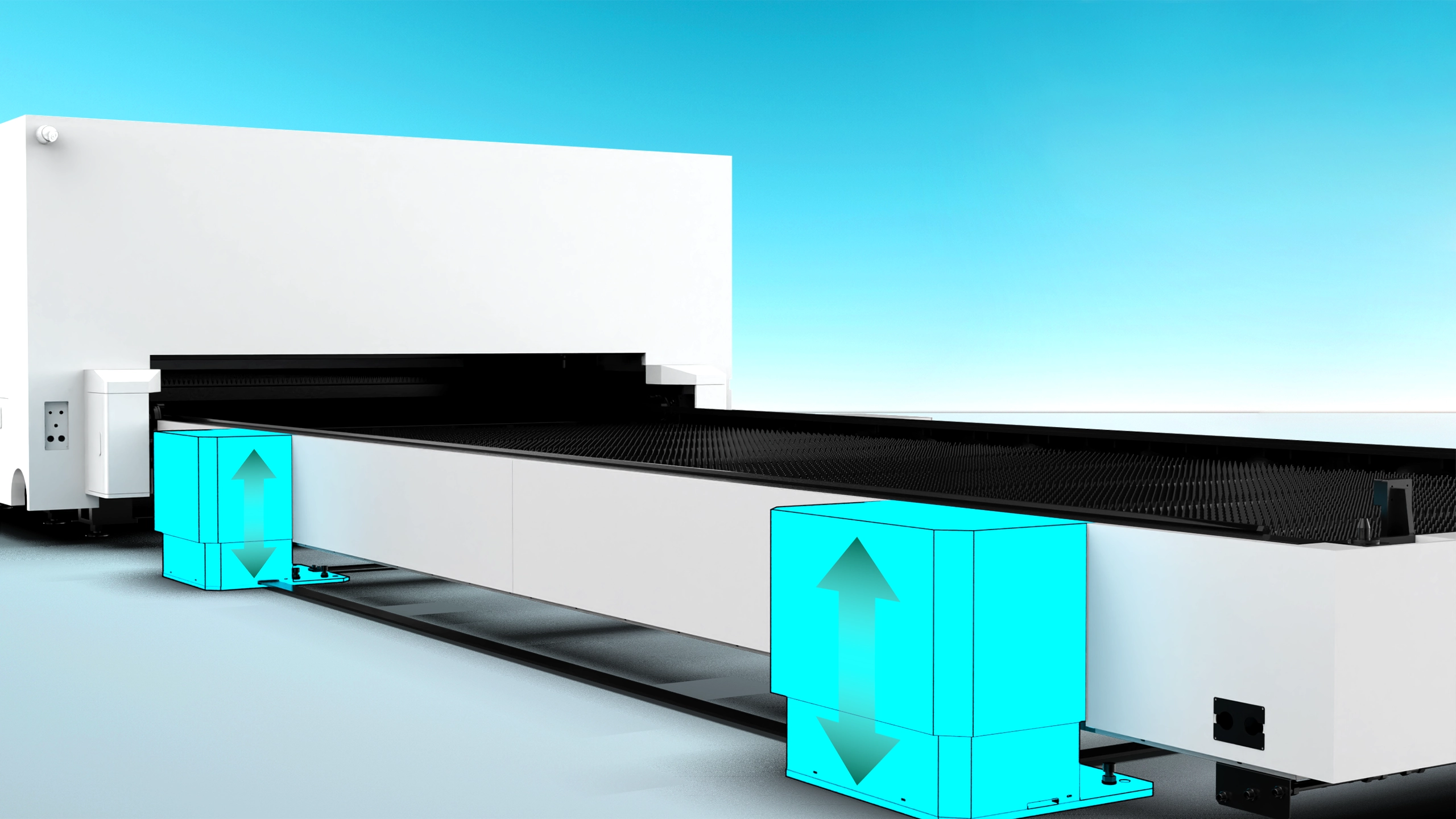

Hydraulic Lifting Bed

The hydraulic lifting structure enables smooth and precise height adjustment, ensuring stable support for heavy sheets and easier material handling. Ideal for thick plate cutting and enhanced operational safety.

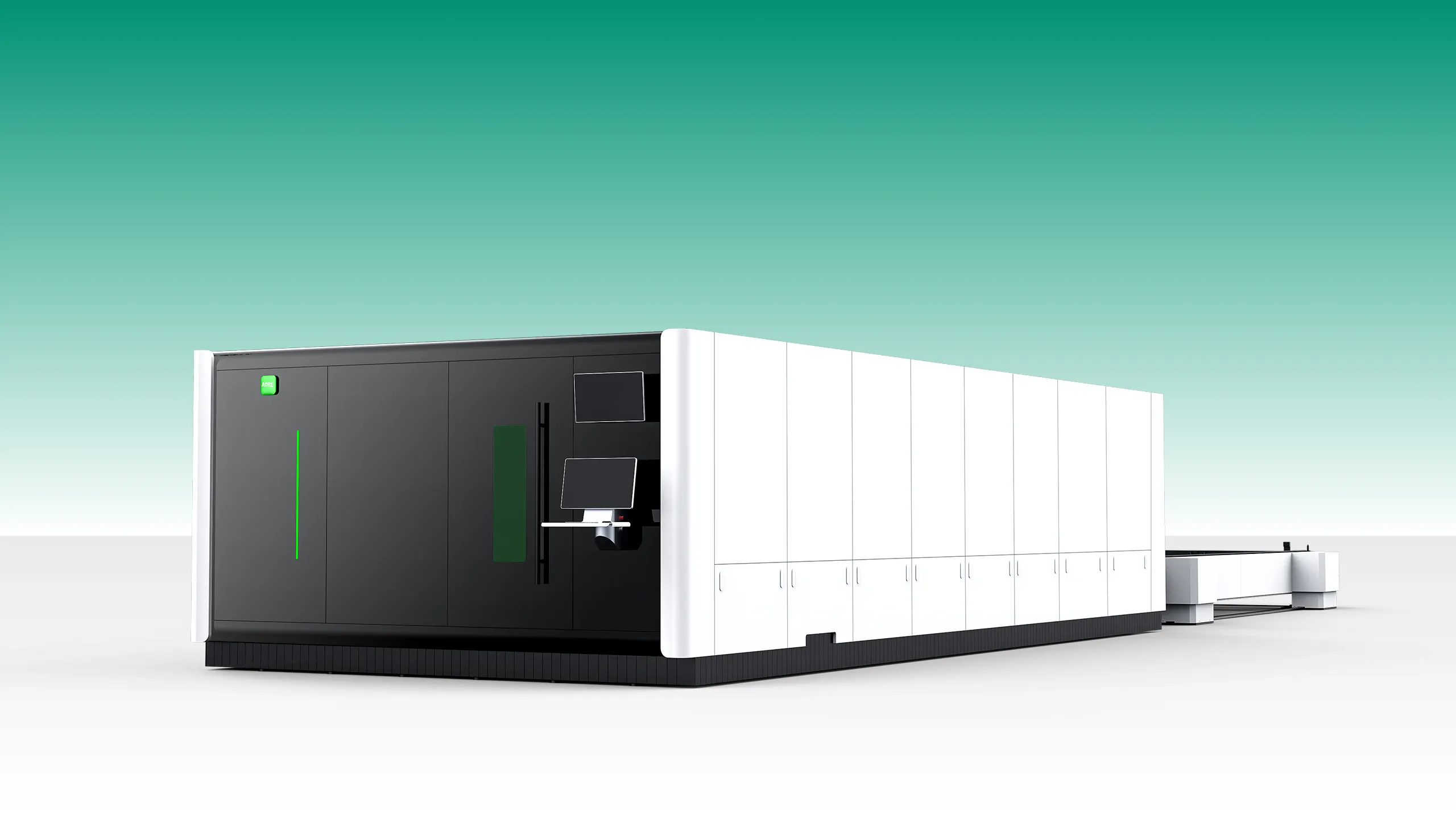

High-Rigidity Frame for Long-Lasting Precision

Upgraded structure with anti-burning design minimizes thermal deformation, enabling smoother high-speed operation and stable cutting accuracy.

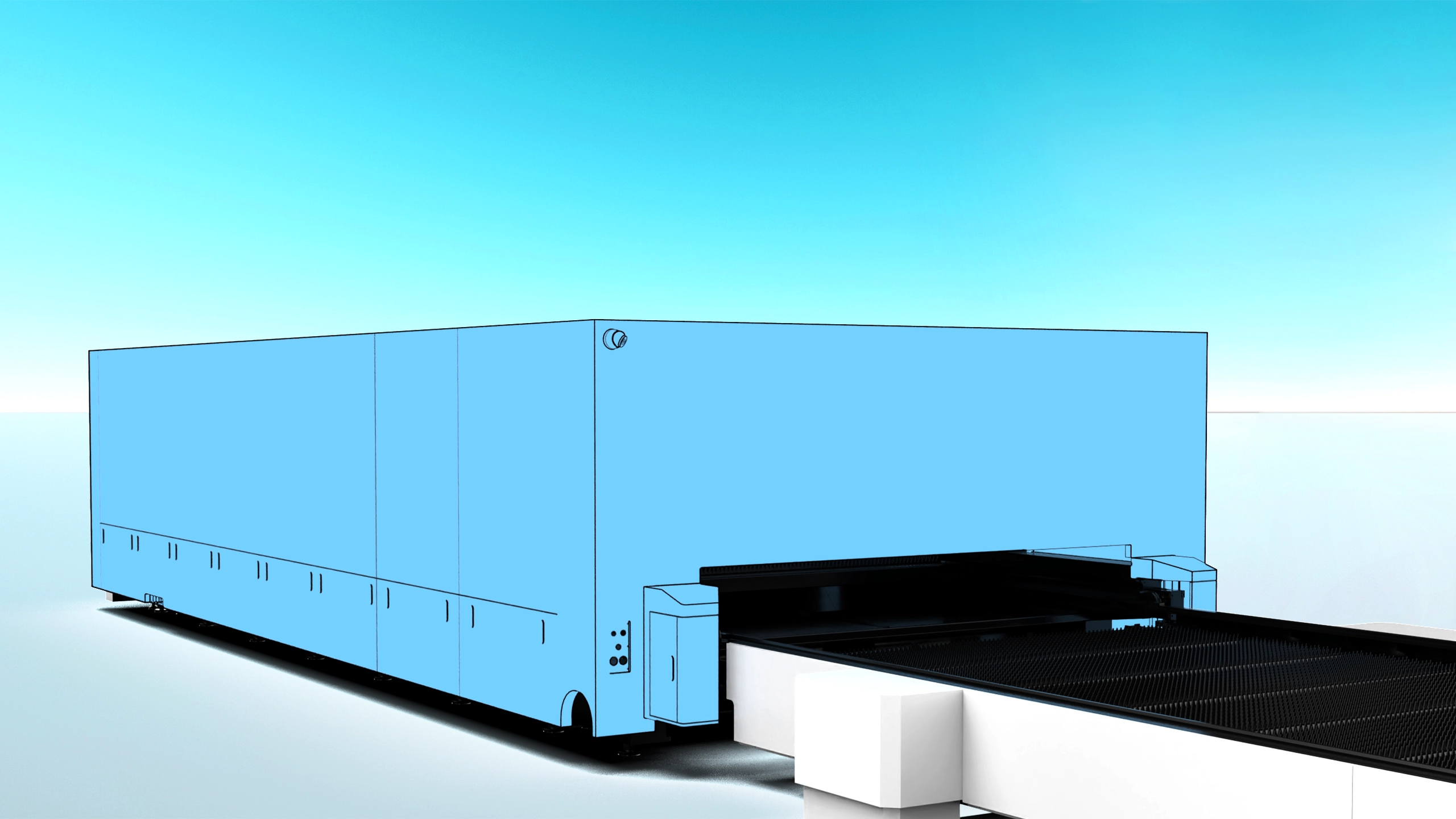

Fully Enclosed Safety Protection

Integrated with high-efficiency fume extraction to ensure both operator safety and eco-friendly production.

Focus on thick plate groove processing

Efficiently achieve ± 45 ° groove cutting, V-shaped, Y-shaped, X-shaped, K-shaped and other grooves, forming them in one processing, effectively reducing processing steps and improving efficiency.

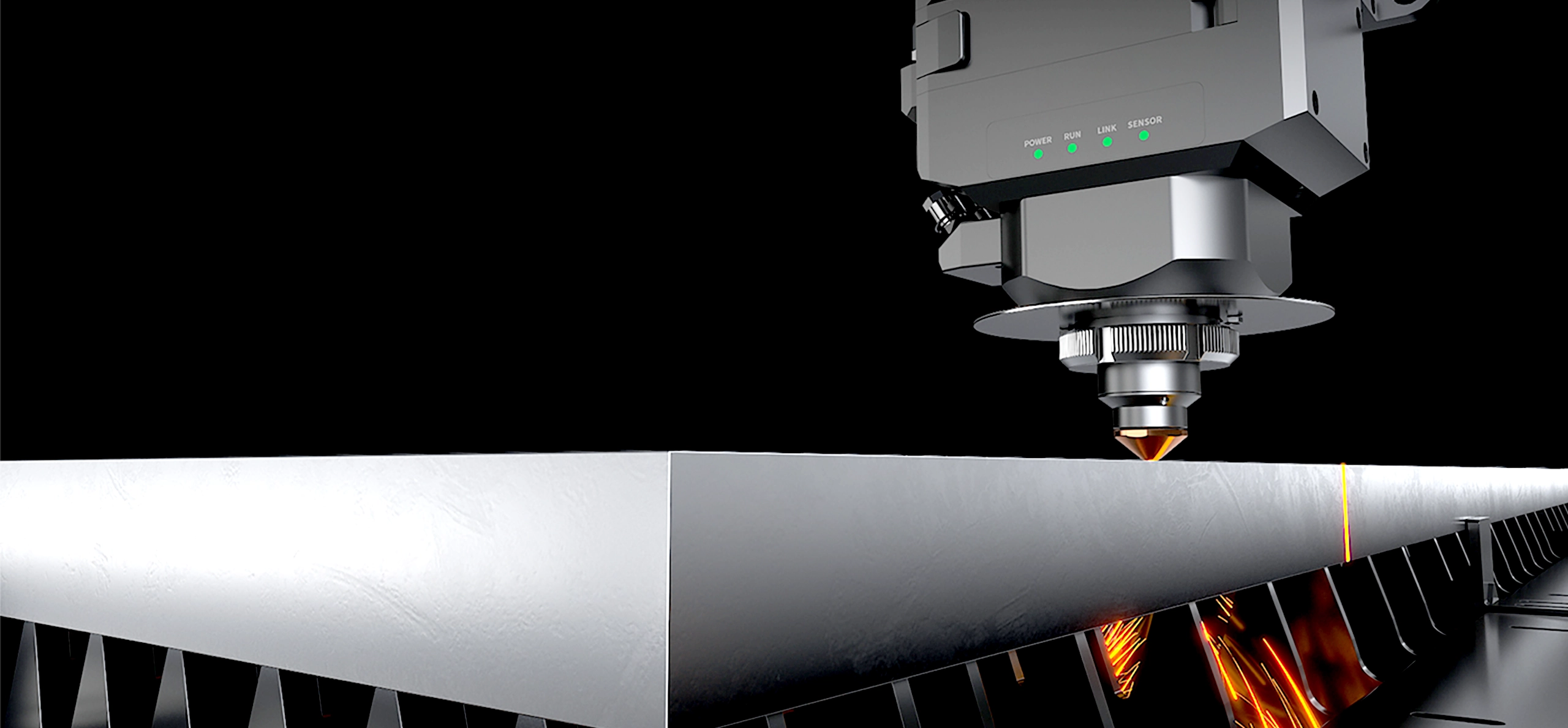

Thick plate cutting process

Easy cutting of ultra thick metal sheets, equipped with high-power lasers to achieve deep penetration, high-speed cutting, and stable processing.

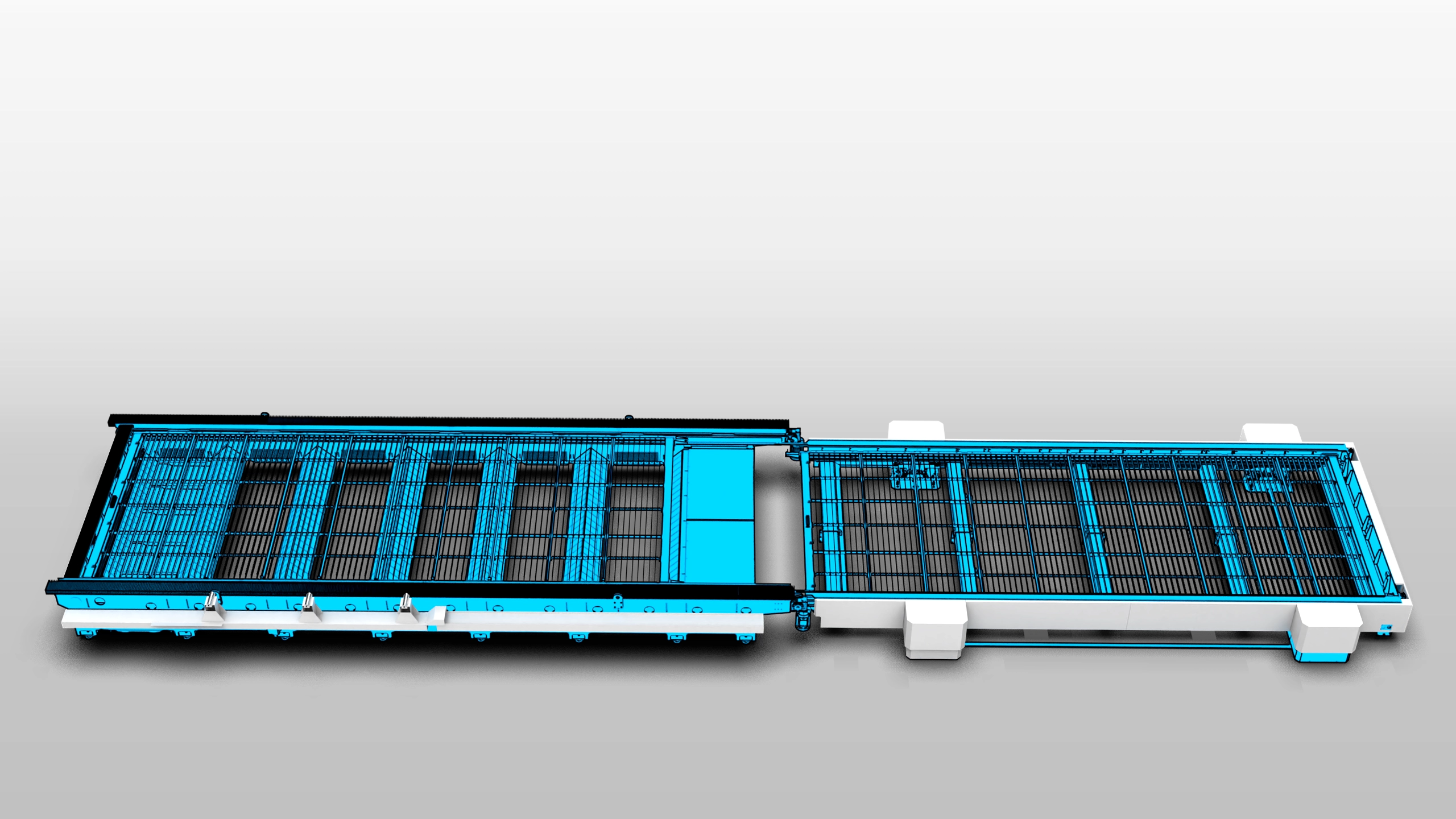

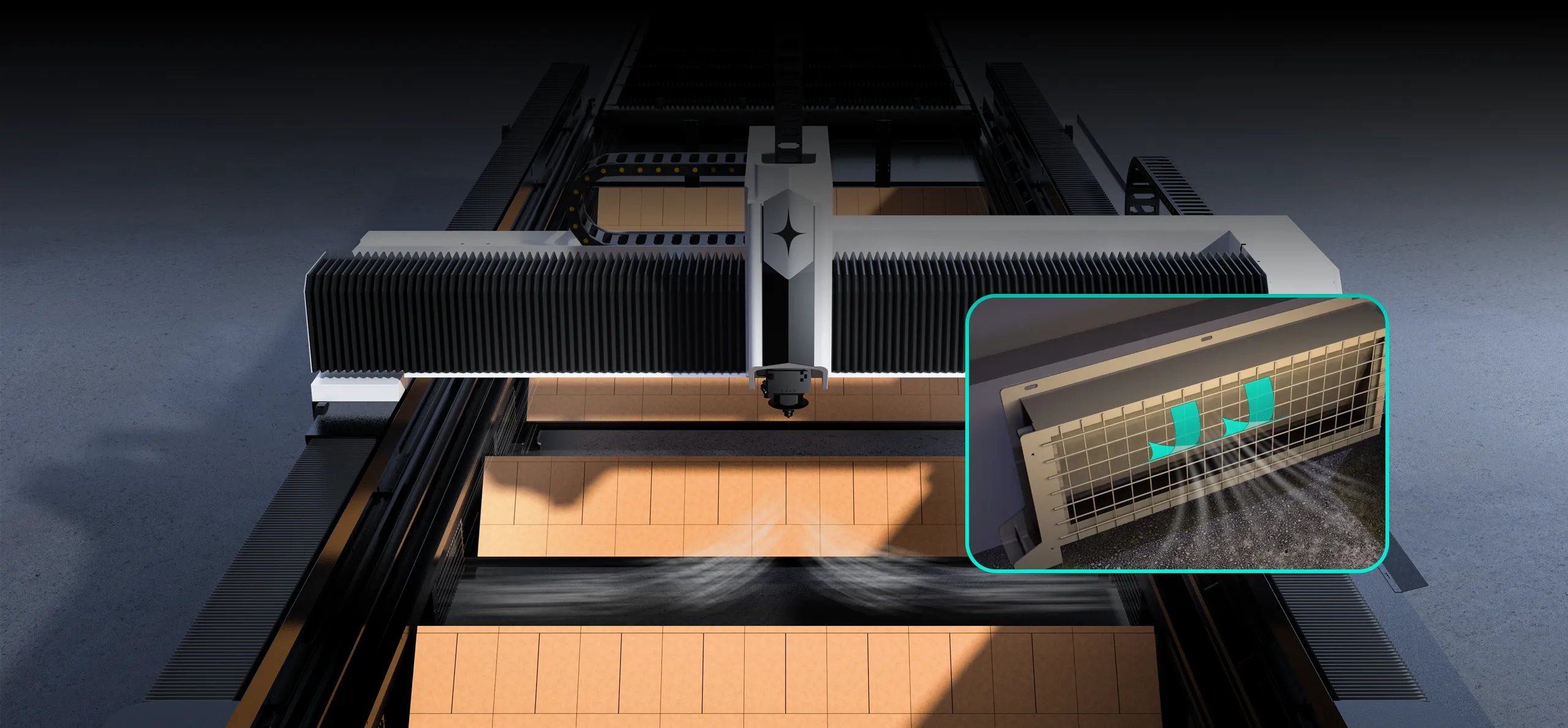

New anti burning and insulation technology, fearless of thermal deformation

The bed body is made of mineral fireproof material, which can effectively reduce the probability of thermal deformation during machine tool processing and improve the service life of the equipment.

Strong ventilation and dust removal

Hydraulic lifting bed design, the worktable is closer to the exhaust port, with strong exhaust effect and significant dust removal.

Applications

Shipbuilding

Steel Structures

Bridge Construction

Construction Machinery

Heavy Equipment Manufacturing

Technical Parameters

| Model | PB3015 | PB6020 | PB8025 |

|---|---|---|---|

| Power | 8-40kW | 8-40kW | 8-40kW |

| Processing Format | 3850*2200mm | 6850*2700mm | 8850*3200mm |

| Maximum Speed | 115m/min | 115m/min | 115m/min |

| Maximum Acceleration | 1.2G | 1.2G | 1.2G |

| Positioning Accuracy | ±0.3mm | ±0.3mm | ±0.3mm |