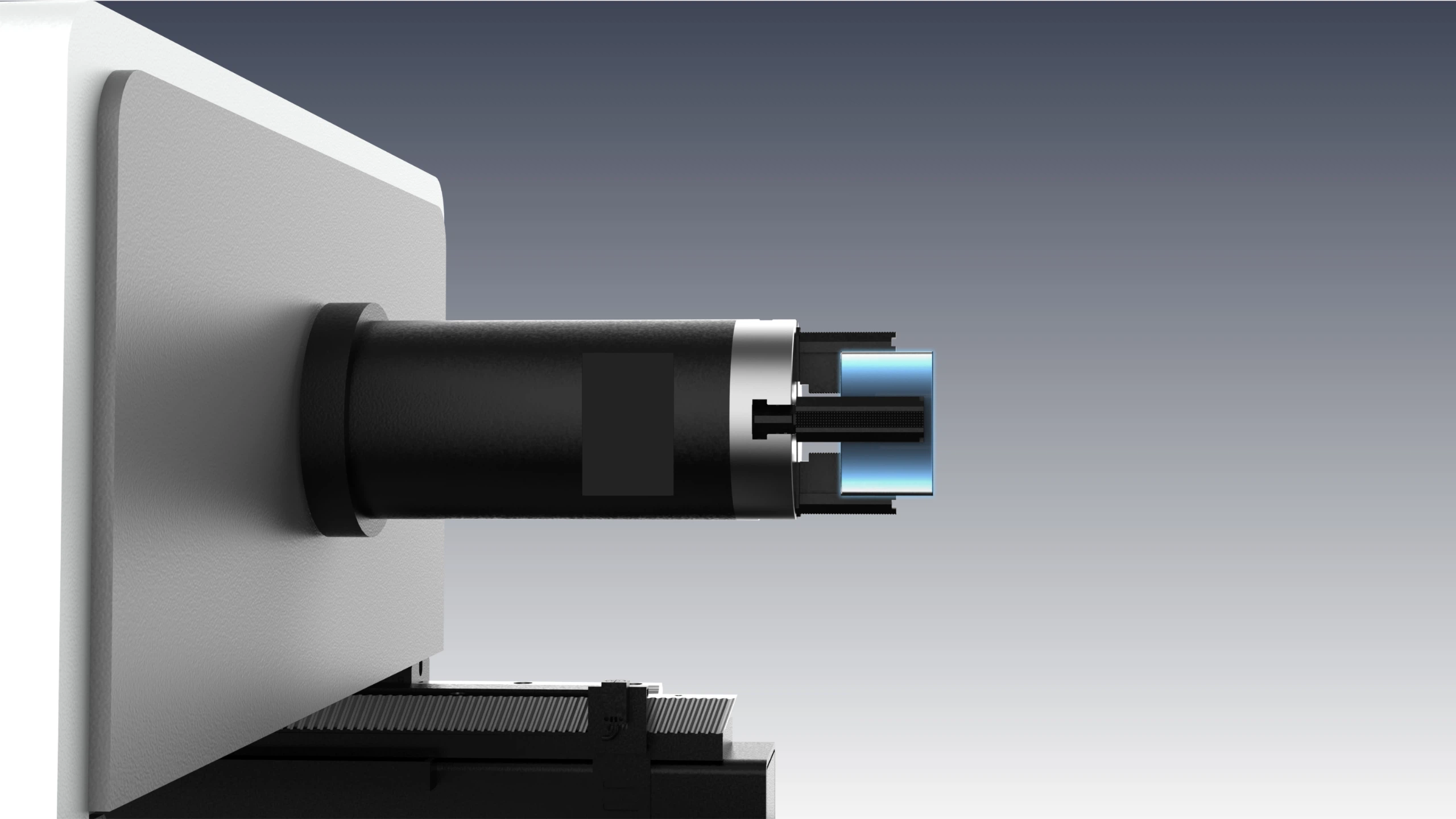

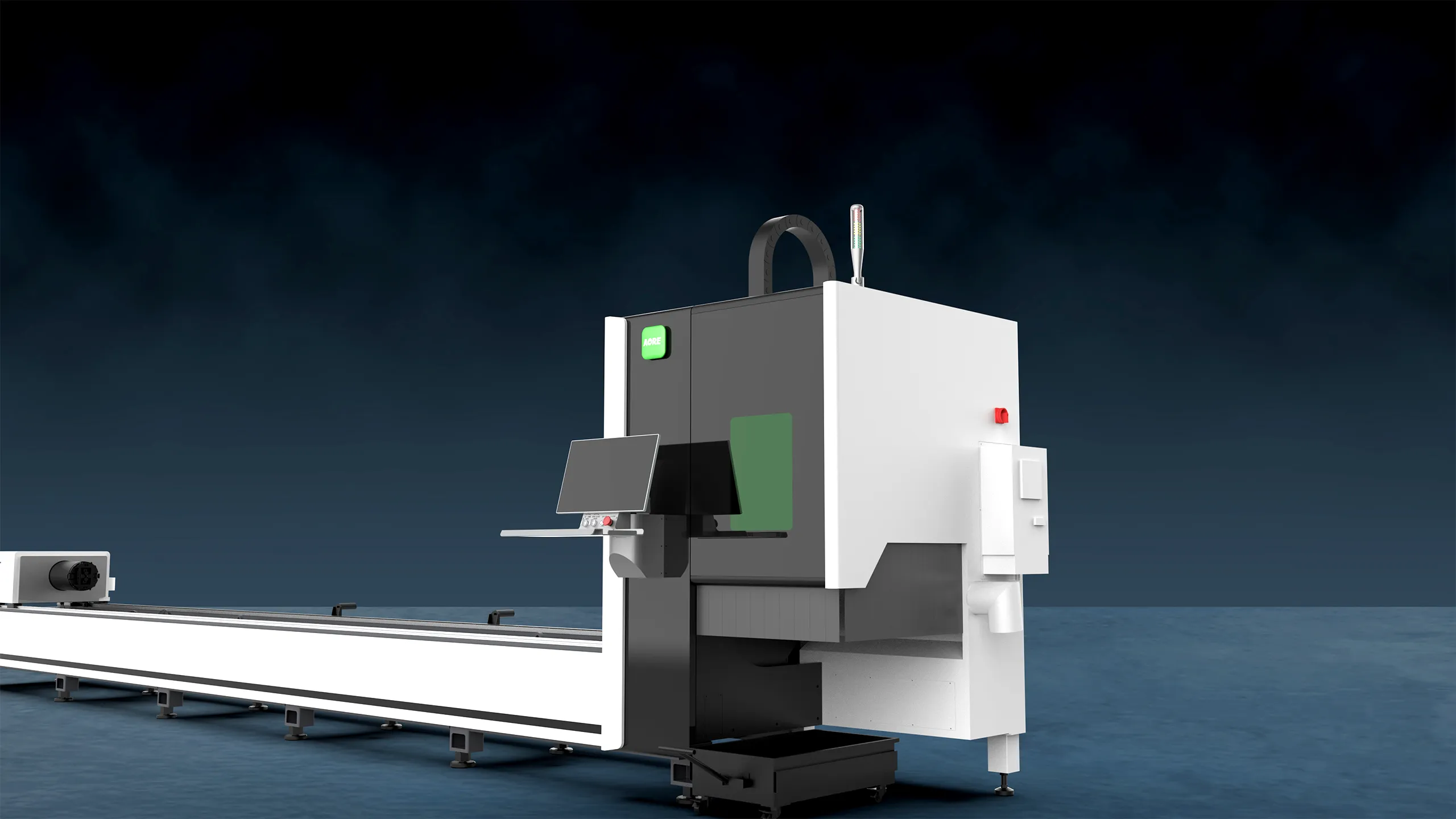

High-Power Laser Source

Enables high-speed. High-precision tube cutting with exceptional performance and reliability

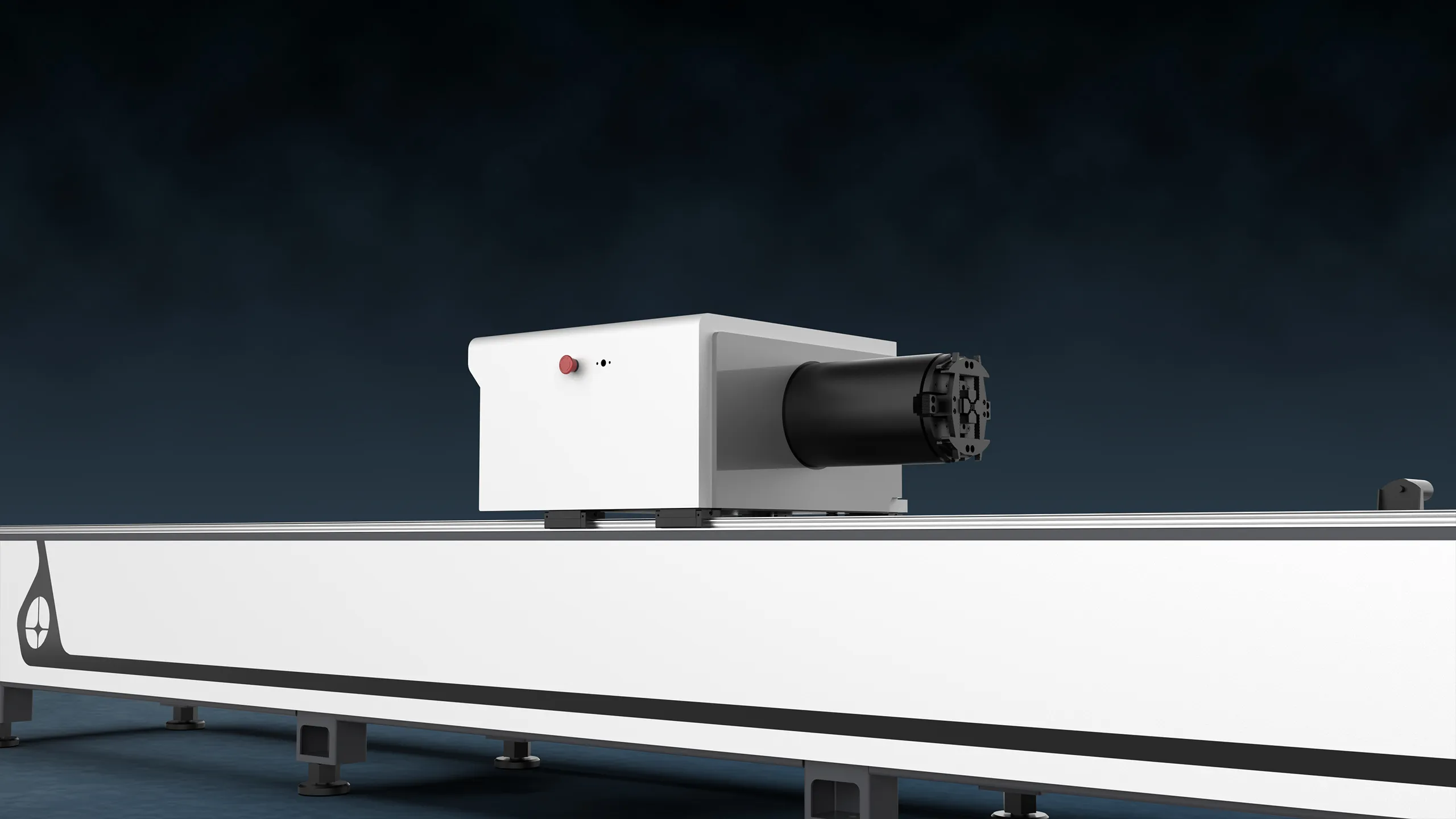

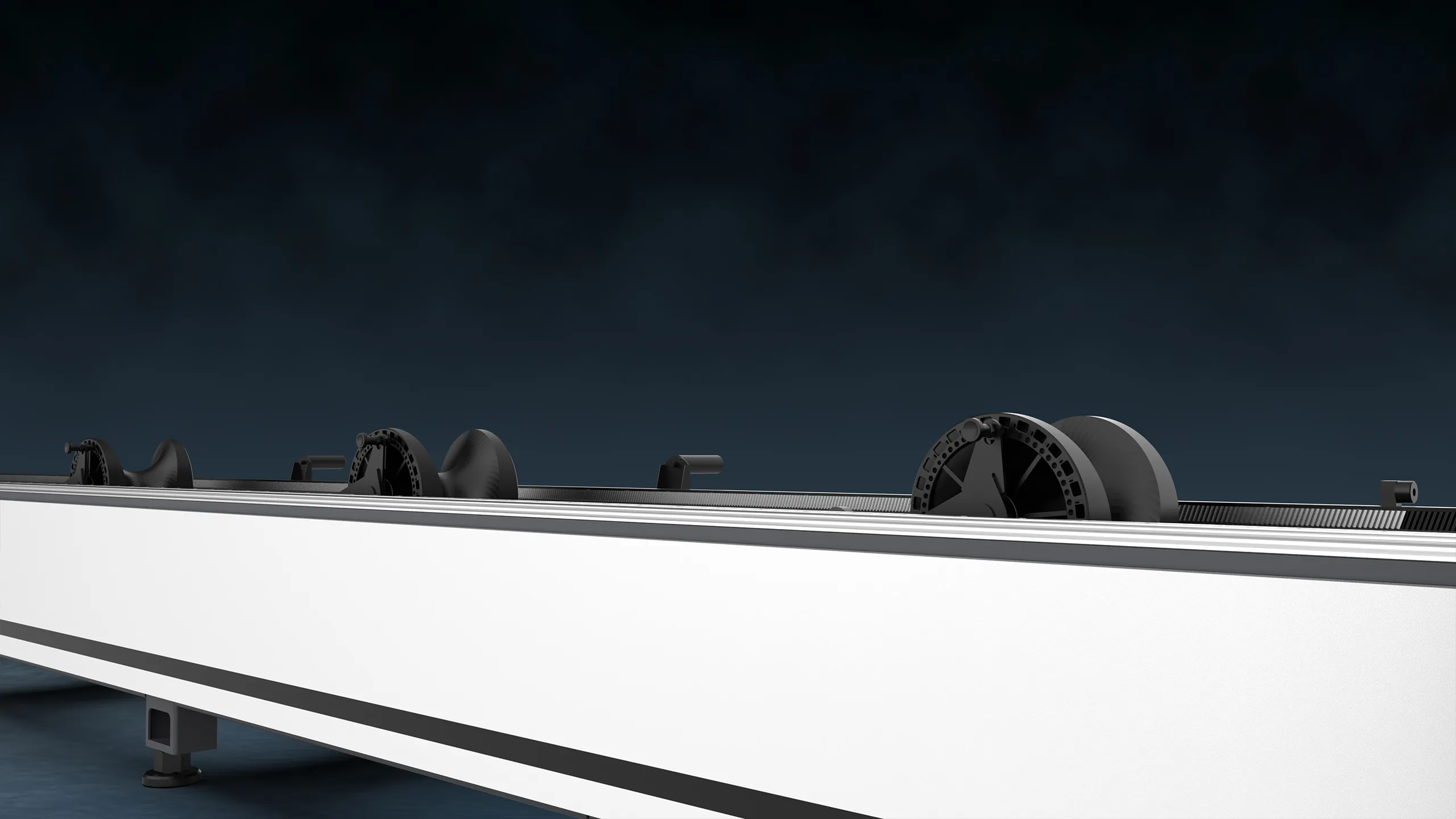

Flexible Chucks

Supports multi-chuck configurations and automation integration to meet customized production line requirements

Ultra-Short Tail Material

Maximizes cutting efficiency while minimizing raw material waste, significantly reducing per-unit processing costs.

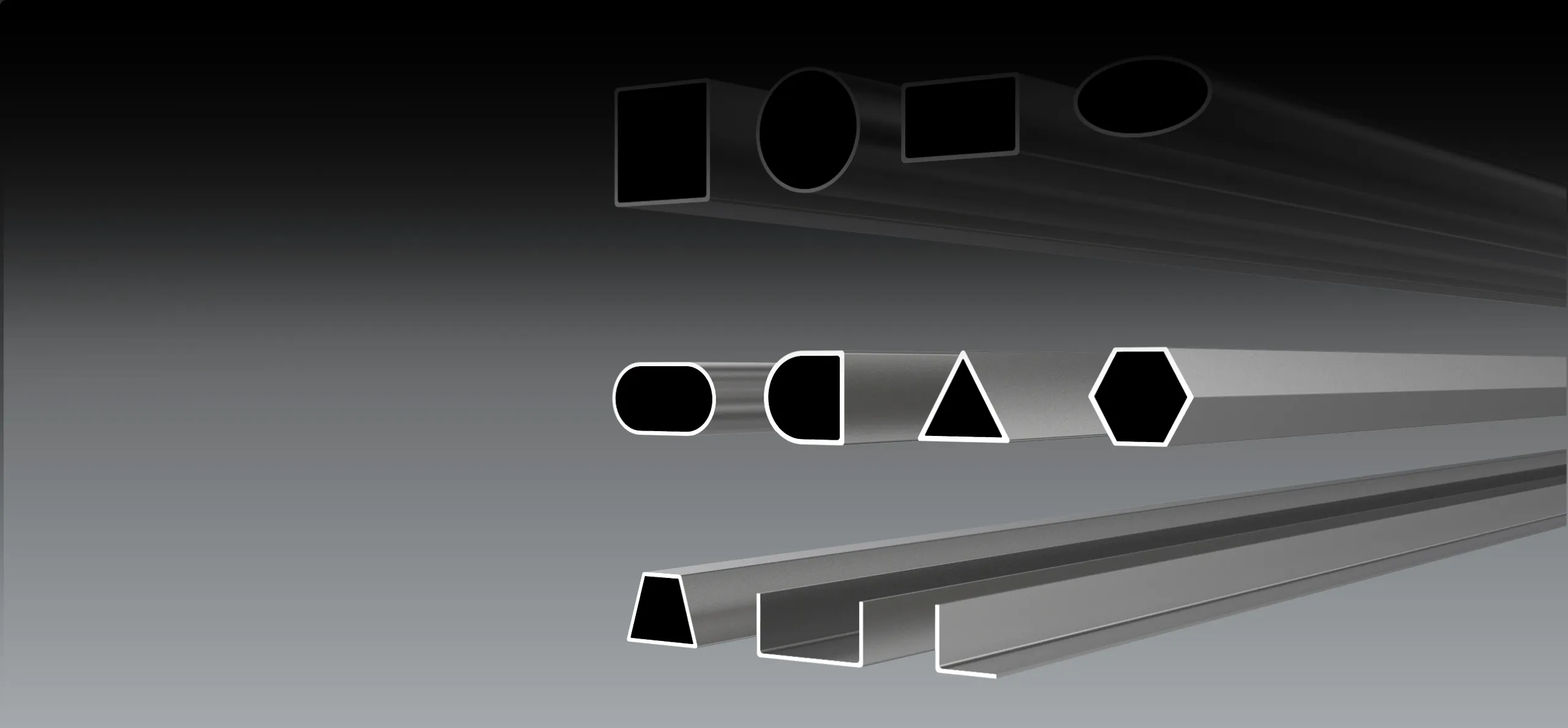

Versatile Cutting Applications

Supports cutting of tubes with complex geometries and cross-sectional shapes, offering flexible adaptability to a wide range of working conditions and processing requirements.

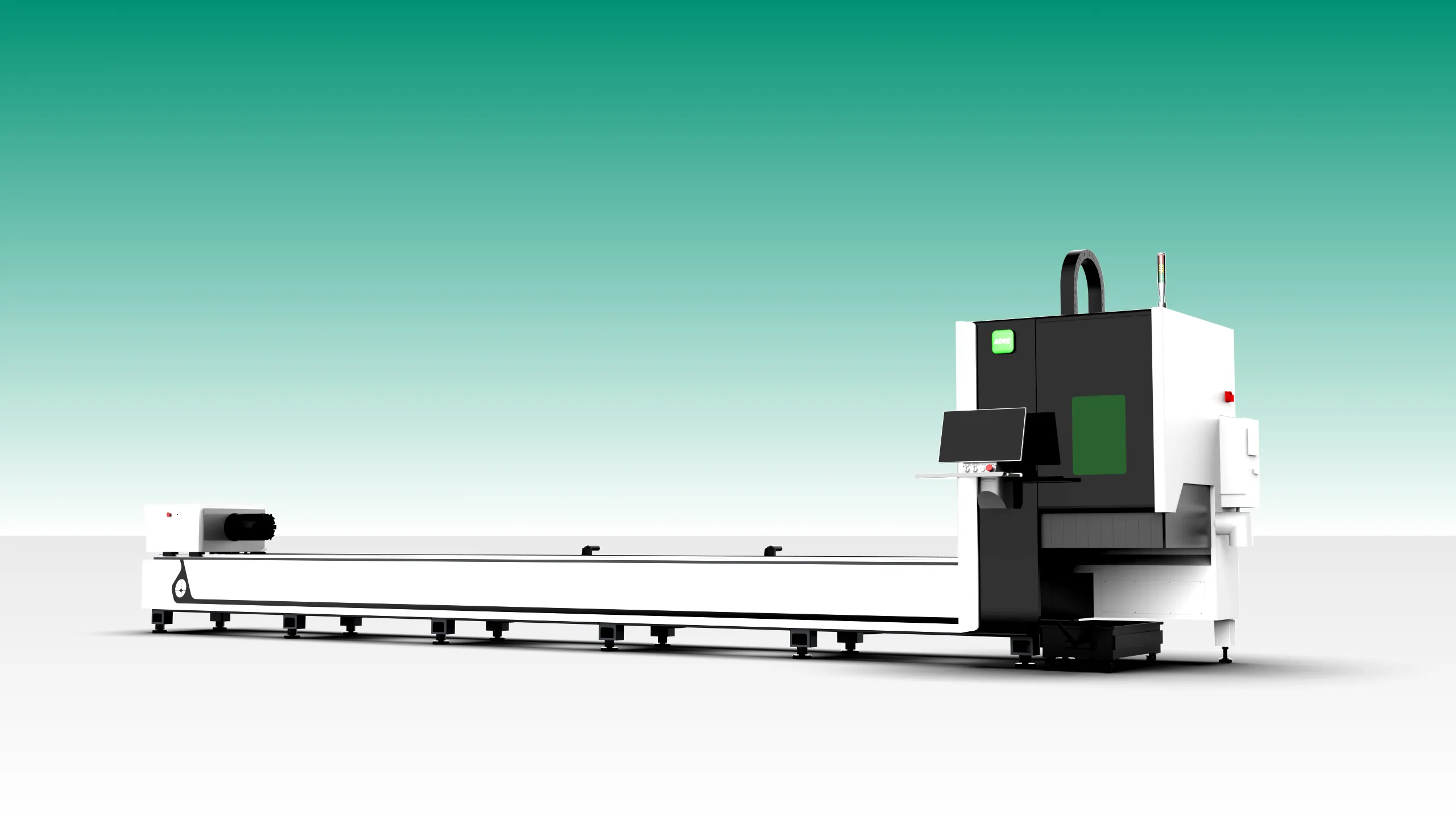

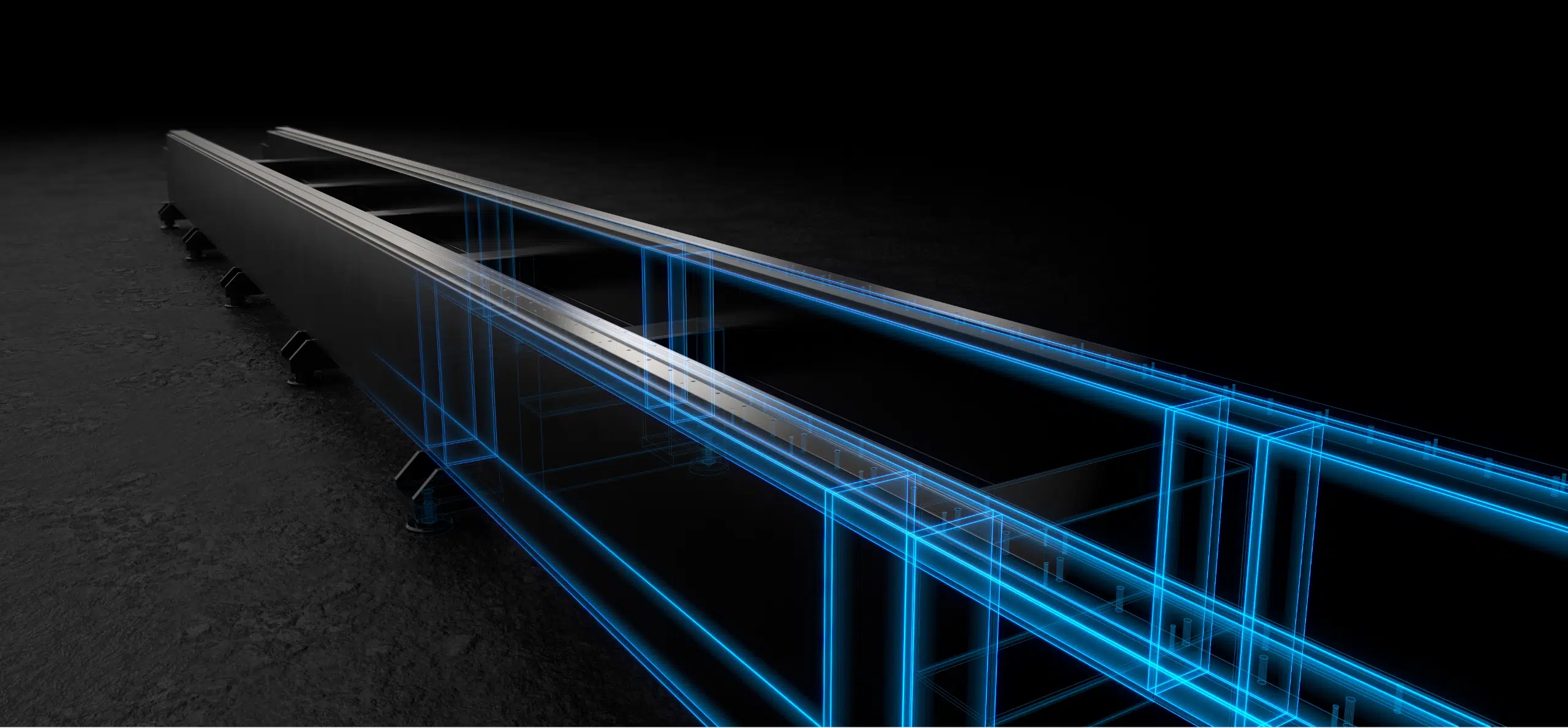

High-Rigidity Horizontal Bed Frame

Built with a robust, heavy-duty structure that ensures strong load-bearing capacity and cutting stability,particularly under high-speed operations involving large-diameter tubes.

Enclosed Safety Protection

The cutting area is equipped with a fully enclosed protective structure to effectively contain sparks and debris, safeguarding operator safety during operation.

Concave Roller Support

Features intelligent height adjustment to work in tandem with the chuck system, effectively preventing sagging or swinging of long tubes. Enhances cutting stability and precision for full-length processing.

Applications

Steel Structure

Automotive

Furniture

Construction Machinery

Pipeline Processing

Technical Parameters

| Model | TG6012 | TG6020 | TG6035 |

|---|---|---|---|

| Power | 1.5-3kW | 1.5-6kW | 3-12kW |

| Processing Diameter | Φ10-Φ120mm □10*10-□120*120mm | Φ15-Φ230mm □15*15-□230*230mm | Φ20-Φ350mm □20*20-□350*350mm |

| Max Load Capacity per Piece | 100kg | 300kg | 900kg |

| Processing Length | 6300mm | 6300mm | 6300mm |

| Maximum Acceleration | 1.5G | 1.5G | 0.8G |