Choose your language

Request A Quote

5 Key Factors to Choose the Right Fiber Laser Welding Machine

In the era of pursuing efficient and precise manufacturing, fiber laser welding technology is rapidly replacing traditional welding methods and becoming a star in the field of metal processing with its significant advantages such as concentrated energy, low heat impact, and beautiful and firm welds. Faced with a wide range of equipment on the market, how to choose a fiber laser welding machine that really suits your needs? It is crucial to master thefollowing 5 core factors:

Power (Laser Power): Match your material thickness and efficiency requirements

Core function: Power directly determines the material thickness and processing speed that the equipment can weld. The higher the power, the thicker the weldable metal and the faster the welding speed.

How to choose Fiber Laser Welding Machine:

Thin plate processing (0.1mm - 3mm): such as stainless steel tableware, electronic components, etc., 500W - 1000W power range is usually efficient enough.

Medium thickness (3mm - 8mm): such as kitchen and bathroom hardware, door and window frames, sheet metal chassis, etc., it is recommended to choose 1000W - 2000W power equipment to ensure melting depth and efficiency.

Thick plate applications (8mm and above): such as heavy machinery, pressure vessels, thick-walled pipes, etc., require high-power equipment of 2000W or even 3000W or above.

Aorelaser solution: Our HW handheld laser welding machine provides a powerful power configuration of 1500W - 3000W, flexibly covering a wide range of needs from thin plate precision welding to medium and thick plate efficient welding. Users can choose the appropriate power level according to the thickness of their main products to avoid insufficient power or waste of resources.

Operation Mode: Balance between flexibility and automation

Main types:

Handheld: Extremely flexible in operation, especially suitable for large workpieces, complex welds, on-site repairs, and small-batch multi-variety production. Quick to get started, relatively low equipment investment cost.

Automated/Robotic: Integrated into a robotic arm or workbench to achieve high-precision, ultra-high repeatability mass production with less manual intervention, but high initial investment and maintenance costs, and programming requires expertise.

Hybrid: Combines the flexibility of handheld with partial automation functions (such as swing welding heads).

How to choose:

Need maximum flexibility to handle a variety of workpieces? Handheld is the first choice.

Pursuing 24/7 continuous, large-volume, ultra-precision production? Consider automation solutions.

Limited budget and changing welding needs? Handheld provides an excellent cost-effective and adaptable starting point.

Cooling System: Guardian of Stable Operation

Core Function: Lasers generate a lot of heat when working. An efficient cooling system is the key to ensure stable output of lasers and extend the life of core components (especially laser sources).

Main Types:

Air Cooling: Compact structure, maintenance-free (no need to replace coolant), low operating cost. The heat dissipation capacity is relatively weaker than water cooling, and is usually suitable for medium and low power equipment or intermittent work.

Water Cooling: The heat dissipation efficiency is extremely high, which can effectively ensure the long-term continuous and stable operation of high-power lasers. However, the system is more complex and requires regular maintenance (such as water change, antifreeze, anti-scaling), and the size and noise are relatively large.

How to choose:

For handheld devices in the power range of 1500W - 3000W, a high-quality air cooling system (such as that used by HW-324) achieves the best balance in heat dissipation efficiency, maintenance-free and portability, and can fully meet the needs of routine production and maintenance.

For ultra-high power (>4000W) or demanding 24/7 continuous production lines, water cooling is still a necessary choice.

Aorelaser Advantages: HW is equipped with an efficient and intelligent air cooling system, with a dual fan design and optimized air ducts, strong and reliable heat dissipation, truly ready to use, worry-free, especially suitable for workshop environments.

Precision & Efficiency: Beam Quality and Intelligent Control

Key Indicators:

Beam Quality (BPP): The smaller the value, the stronger the beam focusing ability, the more concentrated the energy, the higher the welding accuracy, the smaller the heat affected zone, and the more beautiful the weld. This is especially important for thin plate welding and precision applications.

Pulse/Continuous Mode (Pulse/CW Mode): Continuous wave is suitable for high-speed deep penetration welding, while pulse wave can better control heat input and reduce spatter. It is suitable for thin plates, dissimilar metals, and precision spot welding/seal welding. Does the equipment support flexible switching or has high-frequency pulse capability?

Intelligent functions: Such as real-time weld tracking, power closed-loop control, waveform modulation, etc., can significantly improve welding quality and consistency, and reduce dependence on operator experience.

How to choose: Pay attention to the BPP value of the equipment (usually < 2.0 is better) to understand whether its working mode meets your material and application requirements. Intelligent functions are a powerful weapon to improve production efficiency and quality stability.

Aorelaser technical guarantee: HW-324 uses high-quality fiber laser source with excellent beam quality (BPP < 1.8). Supports continuous/pulse mode, wide pulse frequency range, and adapts to various welding needs. Built-in intelligent parameter database and real-time monitoring protection function help users easily weld perfect welds.

Safety protection (Safety Features): Compliance and responsibility

Core requirements: Laser is a high-energy Class 4 device. Strict safety protection is a mandatory requirement and a manifestation of corporate social responsibility.

Necessary protection:

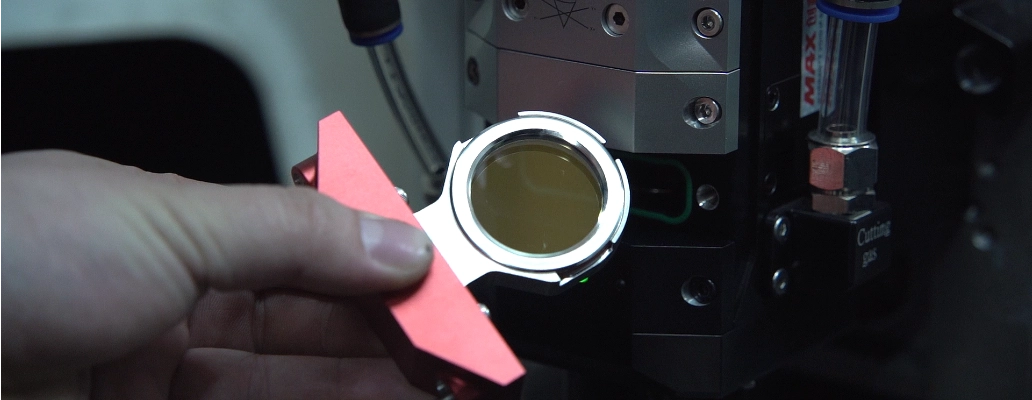

Laser protective glasses: Special protective glasses that match the wavelength of the equipment (usually 1080nm) and have a high enough optical density (OD) must be equipped.

Protective housing/interlock: Fixed equipment should have a protective cover and door lock interlock switch (light stops when the door is opened). Although handheld equipment does not have a housing, operators and on-site personnel must be required to wear protective glasses, and set up warnings and isolation in the work area.

Emergency stop button: Within reach to deal with emergencies.

Safety certification: Ensure that the equipment meets the safety standards of the place of sale/use (such as EU CE, North American NRTL certification, etc.).

How to choose: Absolutely no compromise! The equipment itself should have a complete safety design and certification. Suppliers must provide clear safety training and operating specifications.

Are laser welding machines any good?

Considering the above key factors, Aorelaser HW handheld fiber laser welding machine is your ideal partner for efficient and precise welding:

Multiple power options (1500W/2000W/3000W): Easily handle a variety of material thicknesses.

Extremely flexible and portable: Handheld operation breaks through space limitations and complex welds are easy to handle.

Efficient and intelligent air cooling: Stable and reliable, maintenance-free design greatly reduces operating costs.

Excellent beam quality: Achieve precise, beautiful and firm welding effects.

Multiple safety guarantees: Meet international standards, equipped with professional protection, and safe operation.

Intelligent and easy to use: Humanized design, short learning curve, and immediate production efficiency.

Investing in a suitable fiber laser welding machine is a key step to improve your production competitiveness, product quality and profitability. Clarify your core needs and carefully select according to these five factors. HW-324 is ready to inject powerful momentum into your business!

Maybe you like

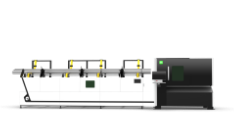

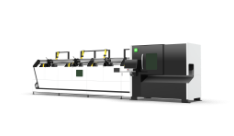

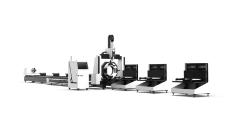

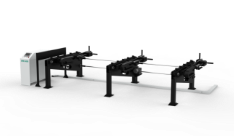

2025 High-efficiency Fiber Tube Laser Cutting Machine

2025-06-12

How to clean industrial laser cutting machine laser lenses?

2025-04-27

Factors affecting the cutting effect of laser metal cutting machine

2025-05-10

Buyer’s Guide: How to Choose the Best Tube Laser Cutting Machine

2025-05-16