Choose your language

Request A Quote

What materials can be cut with a CNC laser cutter?

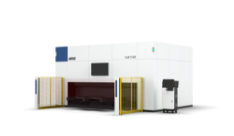

In the world of precision metal fabrication, fiber laser cutting machines have become the gold standard. As a powerful type of CNC laser cutting machine, they offer unmatched speed, accuracy, and versatility. But a common question from manufacturers and fabricators is: "What exactly can I cut with this technology?" Let's dive into the capabilities of the modern metal laser cutting machine, specifically focusing on the dominant fiber laser cutter.

1. What is a CNC Laser Cutting Machine?

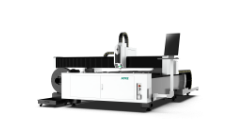

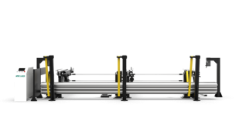

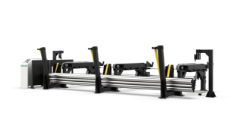

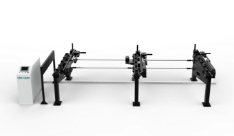

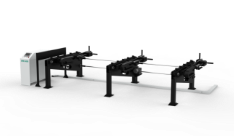

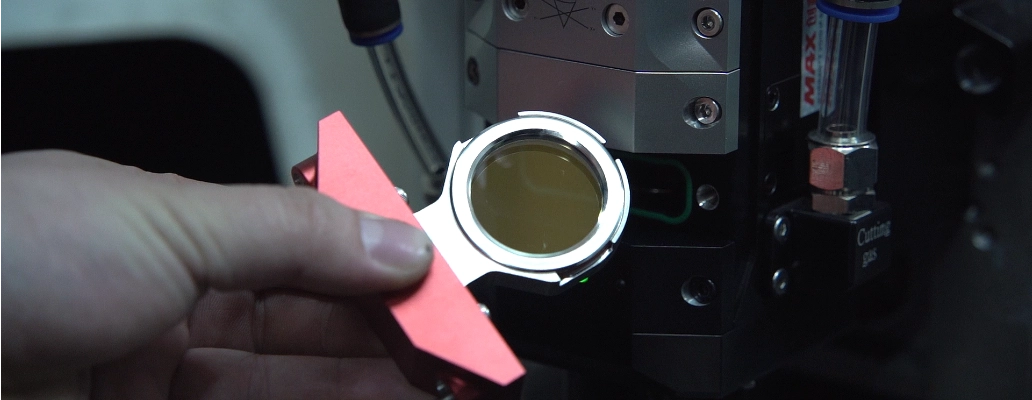

A CNC laser cutting machine is a computer-controlled system that uses a high-powered, focused laser beam to cut, engrave, or mark materials. "CNC" stands for Computer Numerical Control, meaning the machine follows precise digital instructions (typically from a CAD file) to guide the laser head. The two main types are CO2 lasers and fiber laser cutting machines. Fiber laser cutters generate their laser beam within a fiber optic cable doped with rare-earth elements (like ytterbium), delivering the beam directly to the cutting head. This design makes them significantly more efficient, reliable, and powerful, especially for cutting metals, compared to traditional CO2 lasers. They are the premier choice for industrial metal laser cutting.

2. What Materials Can Be Cut with a CNC Laser Cutter? (Especially Fiber Lasers)

The versatility of fiber laser cutting machines is remarkable. They excel primarily with metals but can handle other materials too. Here's a breakdown:

Metals (Where Fiber Lasers Truly Shine):

Mild Steel: The most common application. Cuts cleanly and efficiently.

Stainless Steel: Produces excellent, oxidation-free edges, ideal for food, medical, and architectural applications.

Aluminum: Including various alloys. Fiber lasers handle reflective materials like aluminum much better than CO2 lasers.

Copper: Requires higher power but can be cut effectively with fiber lasers (beware high reflectivity with pure copper).

Brass: Similar to copper, cuts well but requires careful parameter settings.

Titanium: Used extensively in aerospace and medical industries. Cuts well with appropriate gas (usually argon).

Tool Steel: Harder steels used for tooling can be cut.

Galvanized Steel: Common in construction and appliances.

3. How Thick of Steel Can a 1000W Laser Cut?

A 1000W fiber laser cutting machine is a popular workhorse for light to medium-duty fabrication. For mild steel, its cutting capacity is typically:

Clean Cutting: Up to approximately 6-8 mm (0.24 - 0.31 inches). This provides good quality edges suitable for most applications without secondary finishing.

Maximum Cutting: Up to about 10-12 mm (0.39 - 0.47 inches). However, cuts at this thickness will be significantly slower, have a rougher surface finish (more dross), wider kerf, and require optimized gas settings (usually Oxygen for thickness). Quality diminishes noticeably near the max limit.

4. How Thick Can a 4000 Watt Laser Cut?

A 4000W fiber laser cutting machine represents a significant step up in power, handling thicker materials and cutting thinner gauges much faster than a 1000W machine. For mild steel:

Clean Cutting: Up to approximately 16-20 mm (0.63 - 0.79 inches). Excellent quality and speed within this range.

Maximum Cutting: Up to about 25-30 mm (1.0 - 1.2 inches). Similar to the 1000W, expect reduced speed, quality, and increased dross at maximum thickness, often using Oxygen assist gas.

5. What is the Cutting Capacity of a 12kW Laser?

A 12kW fiber laser cutting machine sits at the high end of industrial power, designed for heavy-duty fabrication and processing thick plate extremely efficiently. For mild steel:

Clean & Productive Cutting: Up to approximately 30-35 mm (1.2 - 1.4 inches) with excellent speed and quality using Nitrogen gas.

Robust Cutting: Can efficiently cut up to 40-50 mm (1.6 - 2.0 inches). While still using Nitrogen for cleaner cuts, speeds remain good.

Maximum Cutting (Oxygen Assist): Using Oxygen, a 12kW fiber laser cutting machine can cut mild steel up to 80-100 mm (3.1 - 4.0 inches) or even slightly beyond. However, cuts this thick will have a noticeably rougher, oxidized edge and be much slower. The primary advantage of high power here is productivity on thick plate (20-40mm) rather than just pushing the absolute thickness limit.

Important Factors Affecting Cutting Thickness:

Material Type: Stainless steel cuts slightly thicker than mild steel at the same power. Aluminum cuts thinner than steel. Copper and brass require more power than steel for equivalent thickness.

Material Quality: Clean, homogeneous material cuts better.

Assist Gas: Nitrogen provides clean, oxide-free cuts (best for stainless, aluminum) but requires more pressure/purity. Oxygen allows cutting thicker steel but creates an oxidized edge. Air can be used for thinner, non-critical mild steel cuts to reduce cost.

Cutting Speed: Thicker materials require slower speeds.

Lens Focus & Nozzle: Optimal setup is crucial for maximizing capacity and quality.

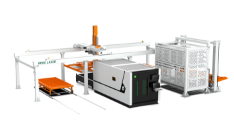

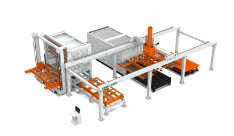

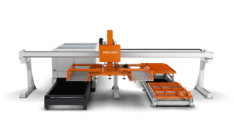

Machine Quality & Stability: A robust machine platform ensures precision, especially at high power and on thick materials.

Conclusion

Modern fiber laser cutting machines are incredibly versatile CNC laser cutters, dominating metal laser cutting across countless industries. From thin, intricate designs in sheet metal to thick structural plate, the range of materials – especially metals like steel, stainless, aluminum, and more – they can process is vast. Understanding the relationship between laser power (like 1000W, 4000W, or 12kW) and its cutting capacity for different materials and thicknesses is key to selecting the right CNC laser cutting machine for your specific fabrication needs. Whether you're producing delicate components or heavy industrial parts, there's a fiber laser solution capable of delivering precision and efficiency.